B21, China Town Mall, Midrand

Plastic Mobile Cover Plastic Injection Molding Machine list YIZUMI Hydraulic Injection Moulding Machine

- Section : Machinery

- Category : Manufacturing Machinery

- SKU : 1600214666393-1723023718

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 05 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the maximum clamping force of the YIZUMI Hydraulic Injection Moulding Machine?

The maximum clamping force of the YIZUMI Hydraulic Injection Moulding Machine is 1200 kN.

2. What are the dimensions of the machine?

The dimensions of the machine are 4.82 meters in length, 1.3 meters in width, and 2.05 meters in height.

3. What is the shot volume of the injection unit?

The shot volume of the injection unit is 46.9 cm³.

4. What is the injection pressure that this machine can achieve?

The machine can achieve an injection pressure of 170 MPa.

5. How many temperature control zones does the machine have?

The machine has 4 temperature control zones.

6. What is the weight of the machine?

The weight of the machine is 4000 kg.

7. What type of control system does this machine use?

The machine uses the Mirle MK500 control system, which provides enhanced performance and stability.

8. Does the machine support hot runner systems?

Yes, the machine expansion of hot runner interface is available, supporting 60 sets of hot runners.

9. What is the maximum injection speed of the machine?

The maximum injection speed of the machine is 94 mm/s.

10. Can the injection unit handle different materials?

Yes, the new universal screw and barrel unit optimizes color mixing and plasticizing efficiency, making it widely applicable.

11. What is the purpose of the low-pressure mold protection feature?

The low-pressure mold protection control unit ensures the effective protection of the mold during the injection process.

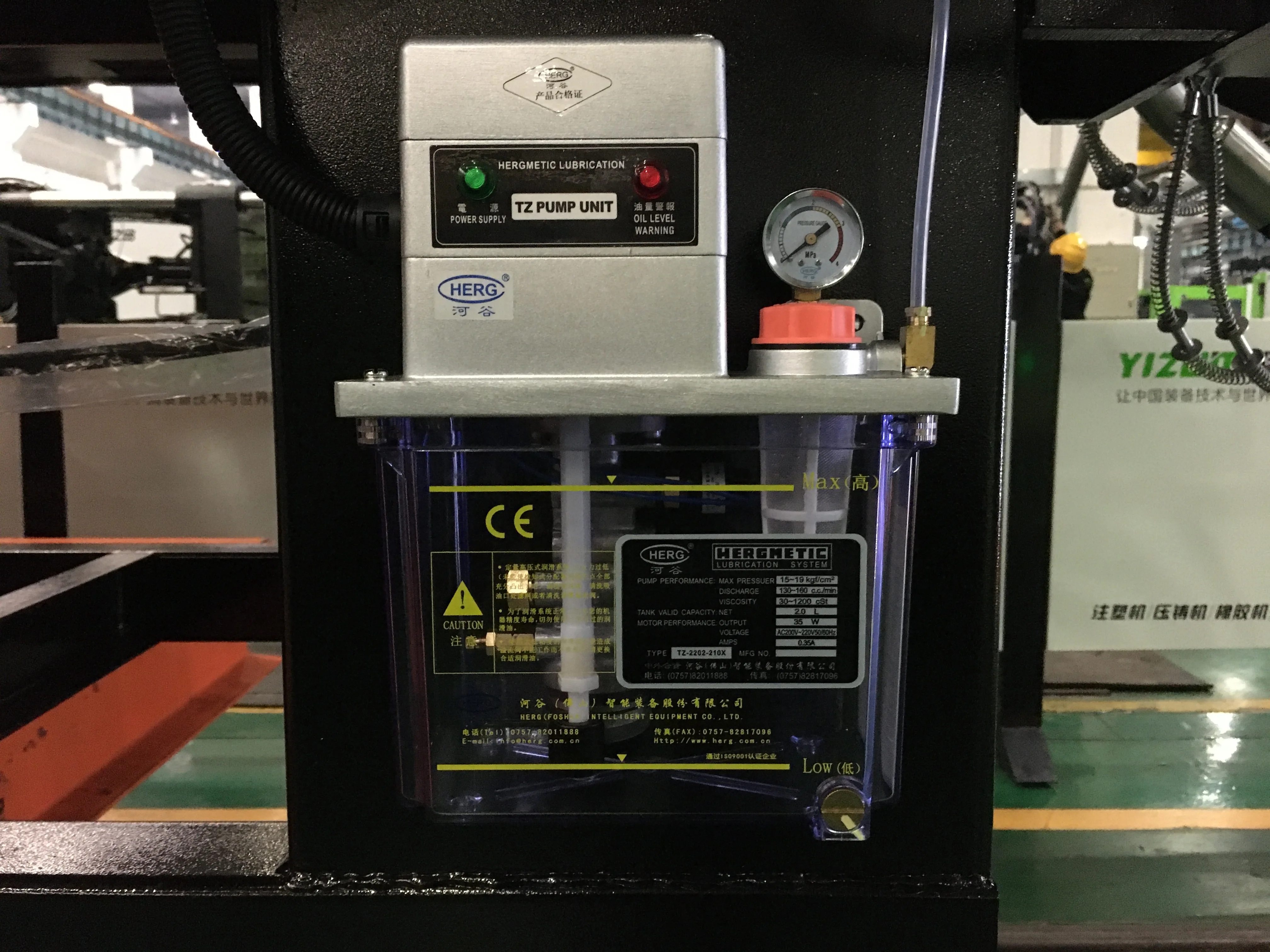

12. How does the centralized lubrication module benefit the machine?

The centralized lubrication module provides easier maintenance and ensures all moving parts are correctly lubricated, reducing wear and prolonging the machine's life.

13. What is the significance of the anti-tilt platen support design?

The anti-tilt platen support design increases the smoothness of motion, lowers friction, improves efficiency, and prevents the platen from tilting, thus protecting the mold.

14. What is the maximum mold thickness supported by the machine?

The machine supports a mold thickness ranging from 145 mm to 450 mm.

15. What is the purpose of the manual lubrication pump in the design?

The manual lubrication pump provides an additional means for operators to lubricate the machine, ensuring optimal performance and reliability.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading