B21, China Town Mall, Midrand

Manufacturing Automatic Solar Strut Channel Roll Forming Machine Bracket Solar Panel Structure making machine

- Section : Electrical & Tools

- Category : Solar Production Lines

- SKU : 1600821686233

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 05 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What materials can the solar strut channel roll forming machine process?

The solar strut channel roll forming machine is suitable for processing materials with a thickness of 0.3 to 0.8 mm.

2. What is the productivity rate of this machine?

The machine has a productivity rate of 10 to 15 meters per minute.

3. What is the width range of the feeding material?

The feeding material width can range from 914 mm to 1250 mm.

4. How many roller stations does the machine have?

The machine can have between 11 to 18 roller stations, or it can be customized based on customer requirements.

5. What is the voltage requirement for this machine?

The machine operates on a voltage of 380V, 50Hz, and 3 phases.

6. What is the weight of the machine?

The total weight of the machine is approximately 11.5 tons.

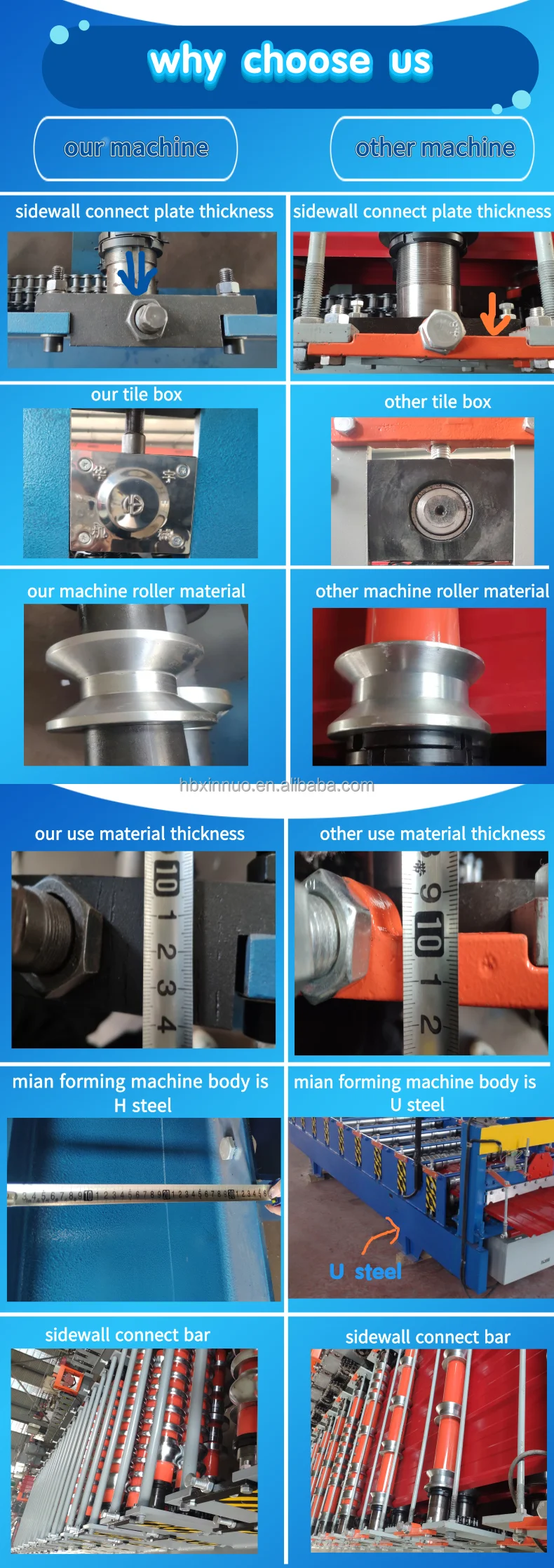

7. What type of steel is used for the rollers?

The rollers are made from 45# steel, ensuring durability and strength.

8. Can the machine be customized?

Yes, the machine can be customized according to the customer's specifications regarding speed, thickness, and the number of roller stations.

9. What is the delivery time for the machine?

The estimated delivery time for the machine is about 20 days.

10. How is the machine packaged for delivery?

The main machine is shipped nude in the container, while the computer control box is packed with a wooden frame for protection.

11. What is the motor power of the machine?

The machine is equipped with a motor power of 22 kW.

12. What is the wall thickness of the main forming machine?

The wall thickness of the main forming machine is between 12 mm and 18 mm steel plate.

13. How does the company ensure the quality of the machine?

The company employs professional engineers to check the quality of each component, ensuring that every step, from roller production to final assembly, meets high standards.

14. What kind of after-sales service is provided?

The company offers after-sales service, ensuring that if customers encounter issues with the control system, they can receive timely assistance.

15. What environmental standards does the machine meet?

The electrostatic spraying equipment used in the machine complies with the environmental protection regulations of the Chinese government.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading