B21, China Town Mall, Midrand

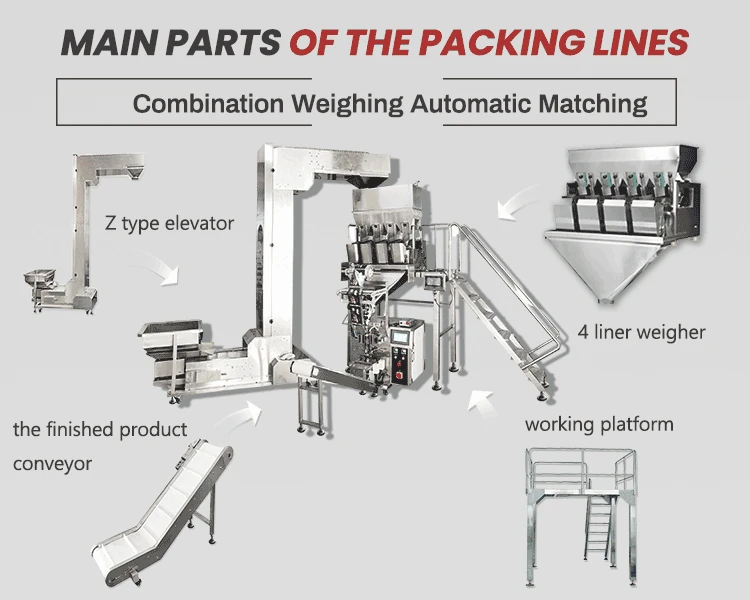

Linear Weigher for Efficient Packaging

- Section : Machinery

- Category : Blister Packaging Machines

- SKU : 1600978388825

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 11 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the Linear Weigher for Efficient Packaging and what are its main benefits?

The Linear Weigher is an automatic weighing machine designed to streamline packaging of middle-granule products. Benefits include faster throughput, reduced manual labor, consistent portioning, improved packaging efficiency, and a hygienic stainless-steel construction suited to multiple industries.

2. Which industries and products is this Linear Weigher best suited for?

It's suitable for food (rice, coffee beans, nuts, raisins, candies), beverage ingredients, chemicals in granule form, and textiles where granular dosing is required. The machine is optimized for medium-size granules and particulates.

3. What packaging types and materials can the Linear Weigher handle?

It supports a wide range of packaging formats including bottles, stand-up pouches, bags and films. It can work with common packaging materials such as plastic, paper, metal, glass and wood-based containers or carriers.

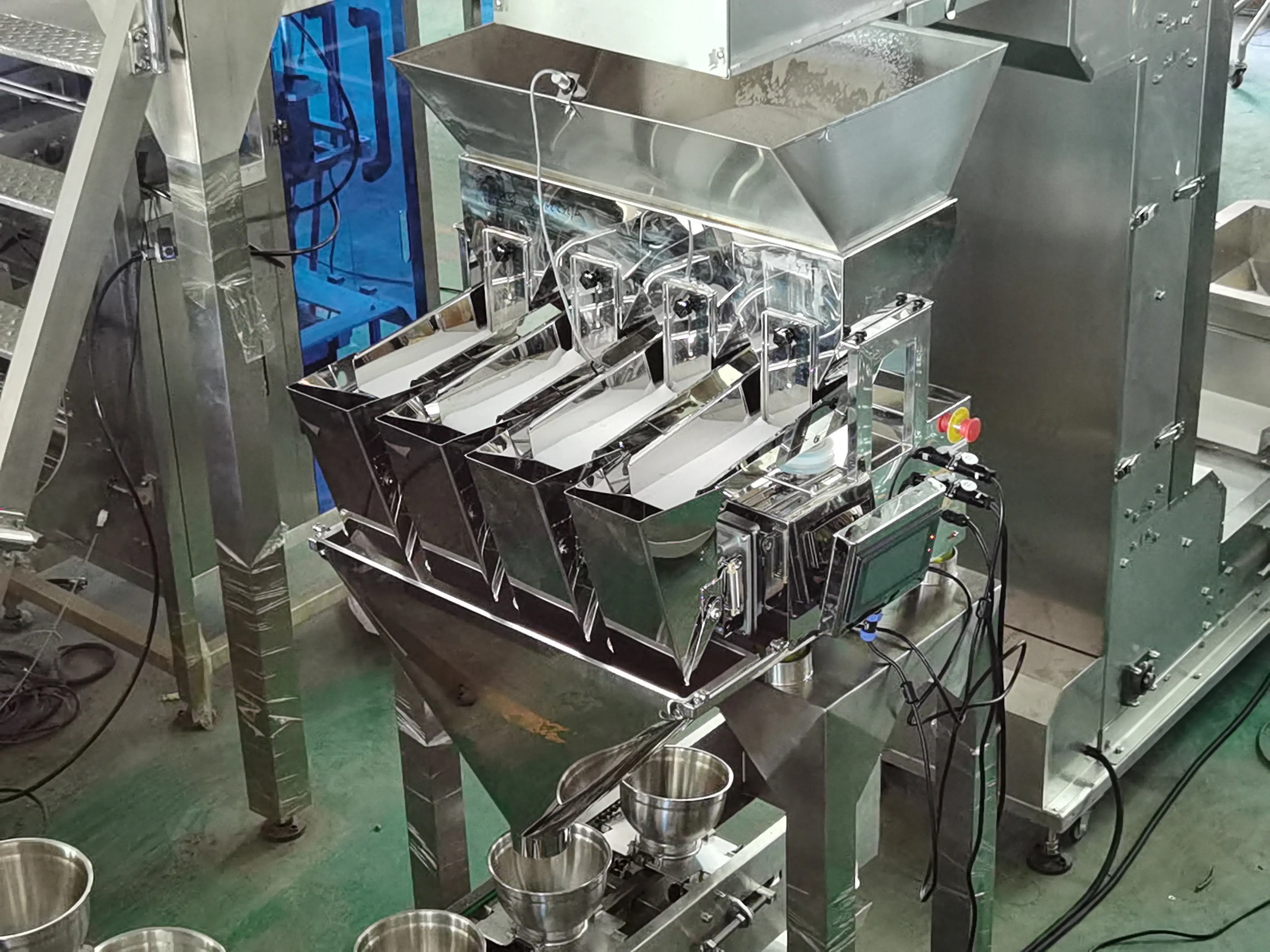

4. What are the machine's construction materials and hygienic features?

The frame and product-contact parts are made from 304 stainless steel, offering good corrosion resistance and hygienic properties. The design facilitates cleaning and meets typical food-industry hygiene expectations.

5. What are the model specifications (volume, controls and interface)?

Typical model details include a 3 L dosing volume and a 7-inch touch-screen HMI. The machine is PLC-controlled for reliable automation and straightforward recipe and parameter management.

6. How accurate and consistent is the weighing?

The Linear Weigher uses PLC-controlled dosing and precise motor-driven feeds to deliver consistent portioning. Actual accuracy depends on product characteristics and target weight; consult the supplier for measured performance data for your product.

7. What are the typical throughput and speed parameters?

Throughput depends on product bulk density, target weight, packaging type and operator settings. The machine is designed for efficient, continuous automatic operation—suppliers can provide estimated packs-per-minute rates based on your product and weight range.

8. Can the Linear Weigher integrate with my existing production or packaging line?

Yes. The PLC control, standardized communications and mechanical interfaces make it possible to integrate with upstream feeders and downstream former/sealer/conveyor systems. Integration options and I/O mapping should be confirmed with the manufacturer or integrator.

9. How user-friendly is the machine and what training is required?

The 7-inch touch-screen HMI and PLC control are designed for ease of use and quick recipe recall. Basic operator training—usually provided by the supplier—covers start/stop, selecting recipes, simple troubleshooting and routine cleaning.

10. How easy is it to change over between different products or bag sizes?

The machine supports quick changeovers by adjusting dosing parameters and making minor tooling or guide changes. The exact time depends on product differences and required mechanical adjustments; modular options can reduce changeover times further.

11. What cleaning and maintenance procedures are recommended?

Regular cleaning of product-contact surfaces with appropriate food-safe detergents is recommended. Routine maintenance includes checking and tightening fasteners, inspecting sensors, lubricating bearings/motors per the manual, and verifying PLC and HMI operation. The 304 stainless construction eases washdown and sanitation.

12. What safety features does the Linear Weigher include?

Standard safety features typically include emergency stop buttons, safety guards around moving parts, interlocks on access panels and compliant electrical protections. Specific safety equipment and certifications vary by supplier and region.

13. Are there optional modules or customizations available?

Yes. Common options include different feeders or vibratory inlets for challenging products, metal detection, checkweighing, printing/labeling interfaces, additional conveyors, custom tooling for special packages and upgraded controls or communications protocols.

14. What are the power and installation requirements?

Power, air and floor-mounting requirements vary by model and region. The machine requires a stable electrical supply and may require a small compressed air line for pneumatic components. Exact electrical specs, footprint and utility needs should be obtained from the supplier or installation guide.

15. What warranty and after-sales support can I expect?

Warranty terms and after-sales support vary by manufacturer and distributor. Many suppliers offer a standard warranty (commonly 12 months), spare parts availability, installation support and optional service contracts. Confirm warranty scope, response times and available training with your vendor before purchase.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading