B21, China Town Mall, Midrand

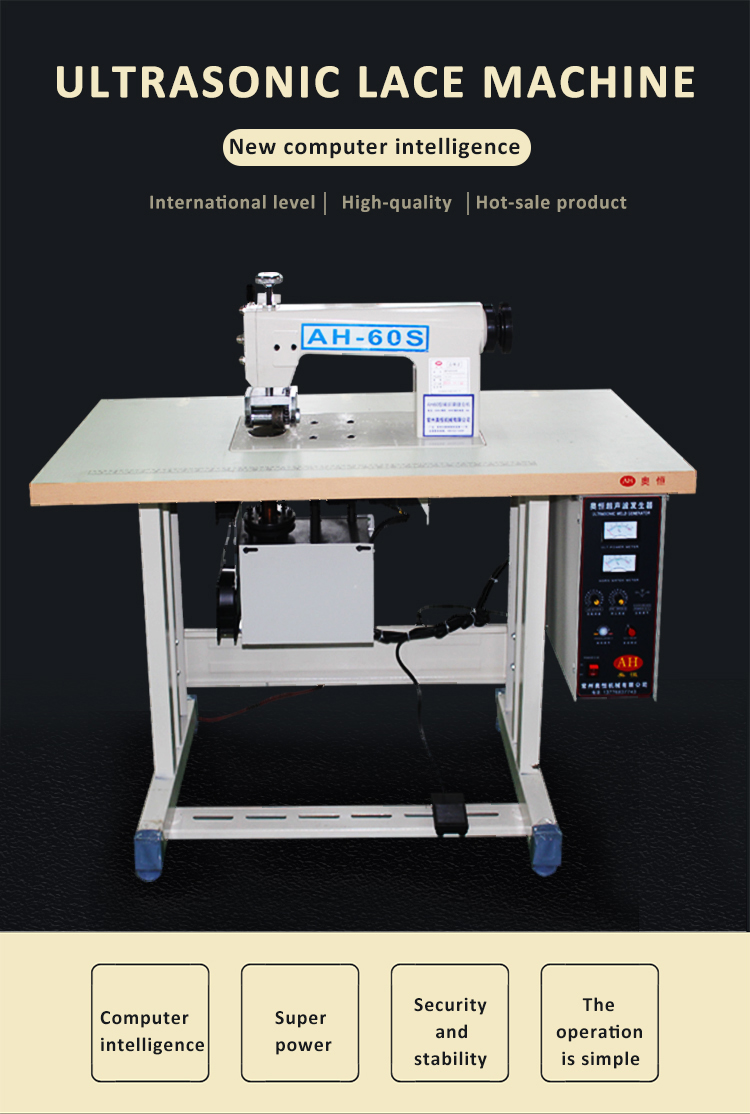

AH-60S industrial surgical gown lace cutting ultrasonic sewing machine

- Section : Machinery

- Category : Sewing Machines

- SKU : 1600117313756

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 05 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the AH-60S industrial surgical gown lace cutting ultrasonic sewing machine?

The AH-60S is an ultrasonic lace machine designed for cutting and sealing/attaching lace and trim used in surgical gowns and similar medical garments using 20 kHz ultrasonic technology.

2. What are the main specifications of the AH-60S?

Output frequency: 20 kHz; Input power: adjustable 1500–2000 W; Running speed: 0–20 m/min; Pattern width: 0–60 mm; Pattern diameter: 50–60 mm; Net weight: 75 kg; Machine size: 11200 × 600 × 1200 (units as supplied); Power supply: 220 V ±5 V, 50/60 Hz, 6 A.

3. Which materials is the AH-60S compatible with?

It is intended for thermoplastic and synthetic textiles commonly used in surgical gown trims and lace (for example non-woven and synthetic lace). For specialized materials or blends, test samples are recommended.

4. How do I adjust the cutting/sealing power?

Input power is adjustable between 1500 and 2000 W. Power adjustments are made via the machine's control interface—refer to the operator manual for step-by-step instructions and recommended settings for different materials.

5. Can I vary the production speed?

Yes. The running speed is variable from 0 to 20 m/min and can be adjusted on the machine to match material feed and desired seam quality.

6. What pattern sizes can the machine produce?

Pattern width can be set from 0 to 60 mm. The specified pattern diameter range is 50–60 mm (confirm exact use of diameter with your supplier if needed).

7. What are the electrical and installation requirements?

Working power supply required is 220 V ±5 V, 50/60 Hz, 6 A. Ensure a stable grounded power source and adequate space for the machine footprint and operator access.

8. How large is the machine and how much does it weigh?

Net weight is 75 kg. Machine dimensions are provided as 11200 × 600 × 1200 (please confirm units and required clearance with the supplier prior to installation).

9. Does the AH-60S use thread or blades?

No thread or conventional cutting blades are required for the ultrasonic cutting/sealing process—the machine uses ultrasonic vibrations to cut and seal edges.

10. What routine maintenance does the machine require?

Regular checks and cleaning of the sonotrode/horn and tooling, inspection of electrical and pneumatic connections, periodic calibration of the ultrasonic generator, and replacement of worn sonotrodes or tooling as needed. Follow the manufacturer maintenance schedule.

11. Are spare parts and service available?

Spare parts such as sonotrodes, horns, and generator components are typically available from the manufacturer or authorized dealers. Contact your supplier for parts lists, lead times, and service options.

12. Is operator training required?

Yes. Proper operator training is recommended to safely set up parameters, perform maintenance, and troubleshoot the ultrasonic system to ensure consistent quality and safe operation.

13. What safety precautions should operators follow?

Follow standard electrical and machine-safety procedures: ensure the machine is properly grounded, keep hands clear of the tooling during operation, use safety guards where provided, and follow the manufacturer's safety instructions and lockout/tagout procedures for maintenance.

14. What kind of cut/seal quality can I expect on surgical gown lace?

Ultrasonic cutting typically produces clean, sealed edges that prevent fraying and produce consistent bonds on compatible thermoplastic trims. Final quality depends on correct power, speed, and tooling settings for the material.

15. Who do I contact for technical support or warranty information?

For technical support, warranty details, and purchase-related questions, contact the machine supplier or manufacturer directly. They can provide documentation, spare parts, maintenance guides, and after-sales service.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading