B21, China Town Mall, Midrand

Winnowing Coriander Seed Cleaning Machine

- Section : Machinery

- Category : Planters & Seeders

- SKU : 1600973156680

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 03 Feb, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

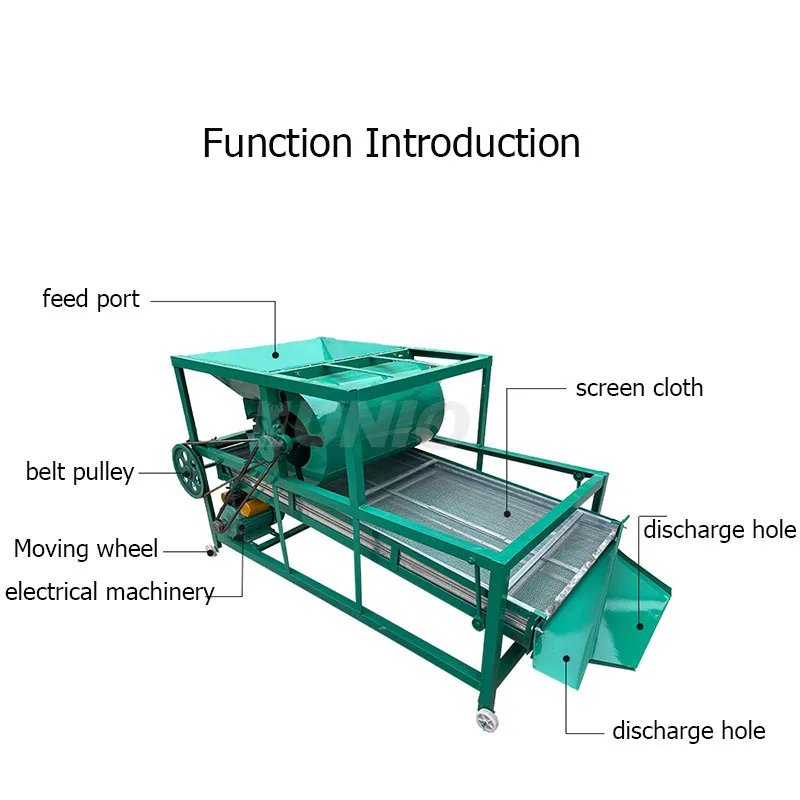

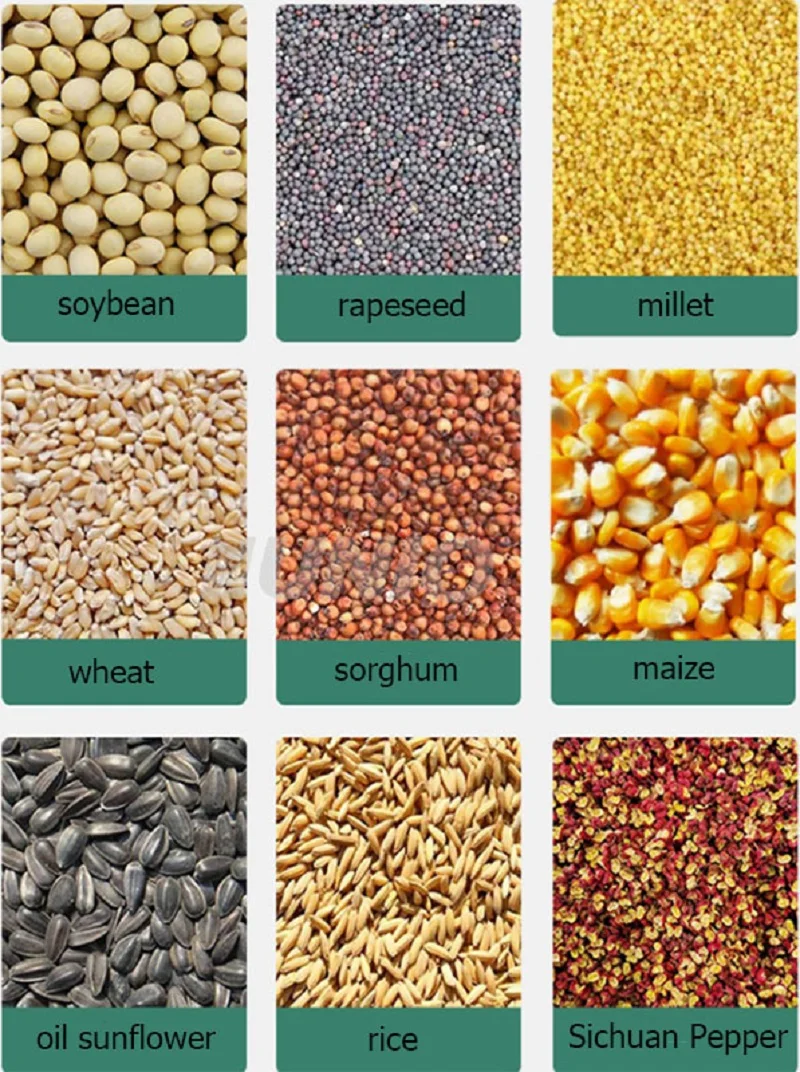

1. What is the Winnowing Coriander Seed Cleaning Machine used for?

This machine is used for selection, grading and removal of impurities from seeds and grains — including coriander, wheat, rice, corn, soybeans, cotton seed and various oilseeds. It separates dirt, debris, bad grains and small stones to improve product quality.

2. What cleaning efficiency can I expect for coriander seeds?

Typical screening and impurity-removal rates are above 95% for seeds and grains. Exact performance for coriander depends on seed condition and screening setup; a trial with your material is recommended for precise results.

3. Which models are available and how do I choose the right one?

Available models are UO-S1, UO-M1 and UO-L1. Their nominal throughputs are approximately 1000 kg/h, 2000 kg/h and 3000 kg/h respectively. Choose based on your required hourly capacity and available floor space.

4. What are the power and electrical requirements?

All models use a rated power of 3.0 kW and run at 1440 RPM. They support 220 V or 380 V supply options — confirm voltage with the supplier to match your site.

5. What is the physical footprint and weight of each model?

UO-S1 dimensions: 1500 × 900 × 900 mm, weight ~80 kg. UO-M1: 2000 × 900 × 900 mm, weight ~110 kg. UO-L1: 2000 × 1300 × 900 mm, weight ~130 kg.

6. What are the screen sizes and can they be changed for coriander seed sizes?

Standard screen panel dimensions are: UO-S1 700 × 1000 mm, UO-M1 700 × 1500 mm, UO-L1 970 × 1500 mm. Hole (mesh) sizes can be configured to suit coriander seed size — contact the supplier to specify the required mesh.

7. Is the motor included in the price?

The listed information states that the price excludes the motor. Confirm motor inclusion and final pricing with the supplier before ordering.

8. What throughput can I expect specifically for coriander compared with other grains?

Throughput varies by seed density and how the machine is set up. As a guideline from similar grains: wheat/rice ~2000 kg/h, corn/soybean ~3000 kg/h, and lighter oilseeds/cotton 500–1000 kg/h. Coriander will typically fall closer to the wheat/rice range but test with your product for an exact figure.

9. How do I install and set up the machine?

Place the machine on a level, stable floor, provide the correct voltage supply (220 V or 380 V), mount/confirm the motor if supplied, connect intake and discharge chutes as needed, adjust screen and air settings (if applicable), then run a test batch and fine-tune feed rate and screen selection.

10. What routine maintenance is required?

Regularly clean screens and the machine interior to prevent blockages, inspect and lubricate bearings and moving parts per supplier guidance, check and tighten fasteners, and replace worn screens or vibration components as needed. Always disconnect power before maintenance.

11. Are spare parts and service available?

The supplier offers spare parts and multiple models; contact them directly to order replacement screens, fasteners, motors or to arrange service. Keep model and serial details ready when requesting parts.

12. Can I get a sample test or demo with my coriander?

Yes — most suppliers recommend sending a representative sample or requesting an on-site/ video demo so the machine can be tuned to your coriander seed size, moisture and impurity profile. Ask the supplier about sample testing options and any associated costs.

13. What safety precautions should operators follow?

Always isolate power before servicing, keep hands and loose clothing away from moving parts, use appropriate guards, train operators on proper feed rates and emergency stops, and follow local electrical and machine-safety regulations.

14. How is the machine packed and shipped?

Packaging and shipping terms vary by supplier and destination. Contact the supplier for details on packing method, freight options, lead time and any export documentation required.

15. How do I get a quote or more technical help?

Contact the equipment supplier directly with your required model (UO-S1 / UO-M1 / UO-L1), desired capacity, voltage, and any special configuration (screen mesh size, motor inclusion). They can provide pricing, lead time, customization and technical support.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals