B21, China Town Mall, Midrand

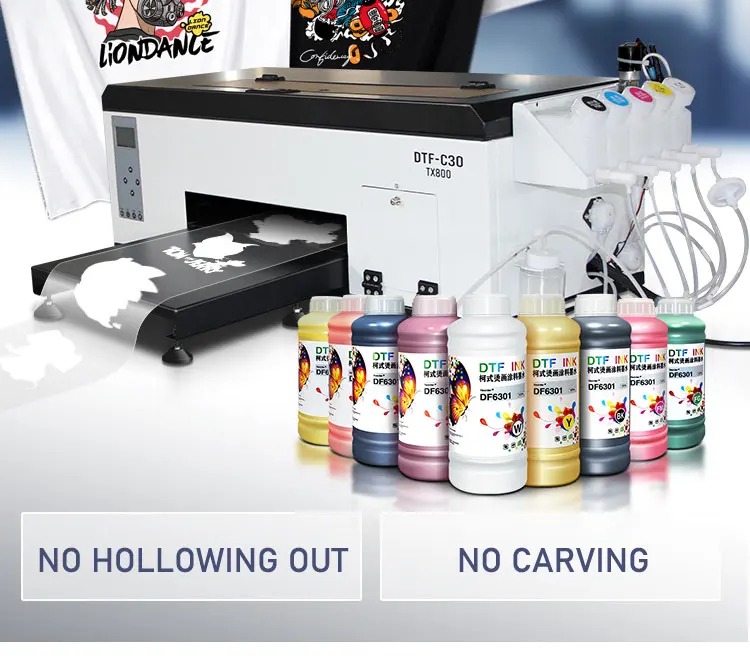

3ALPS TX800 White Ink Stirring/Circulation 30cm Desktop DTF Printer

- Section : Consumer Electronics

- Category : DTF Printers

- SKU : 1600954034185

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 05 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the maximum print width and supported print size?

The printer supports a maximum print width of 330 mm (A3-size). You can print designs up to that width on compatible DTF PET film.

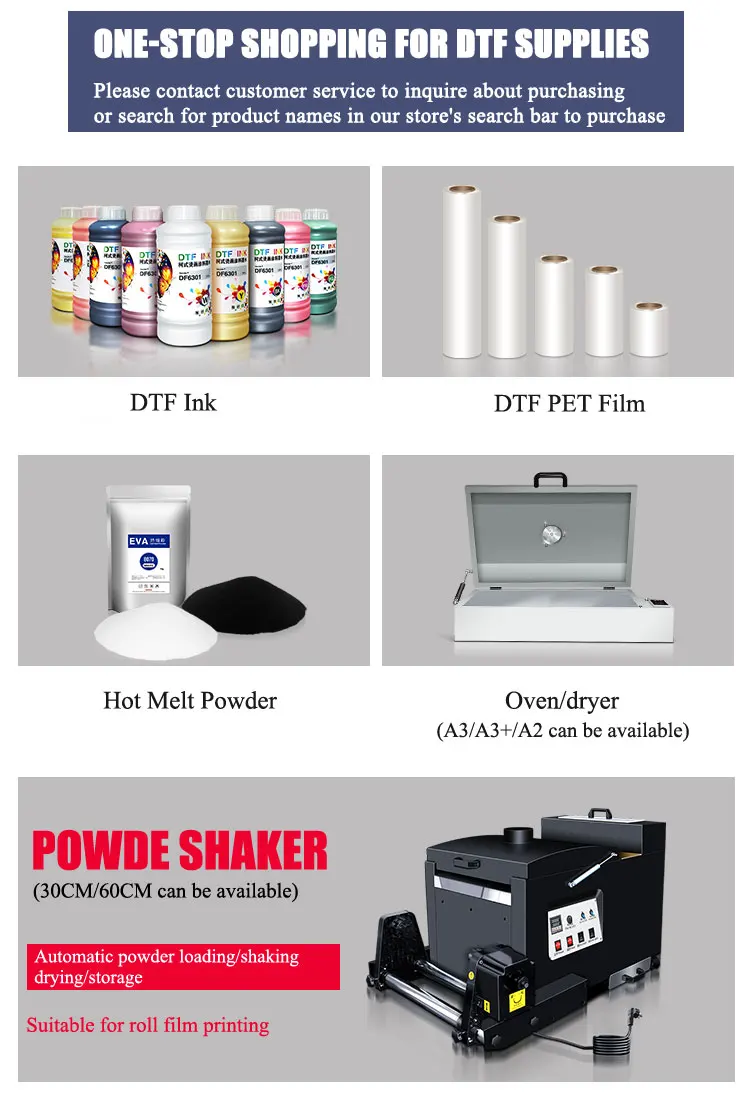

2. What ink configuration does the 3ALPS TX800 use?

It uses a CMYK+W (cyan, magenta, yellow, black plus white) ink configuration with a continuous ink supply system and a 260 ml cartridge capacity.

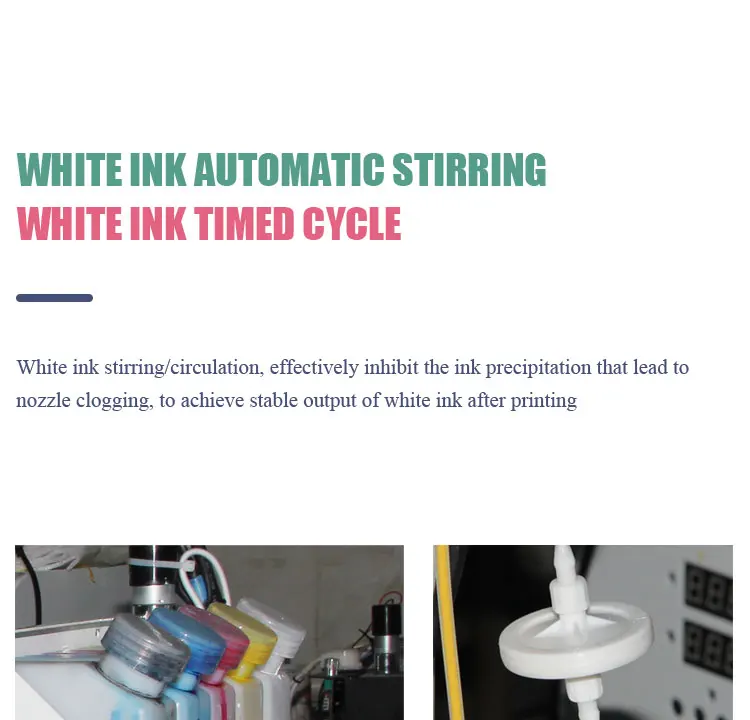

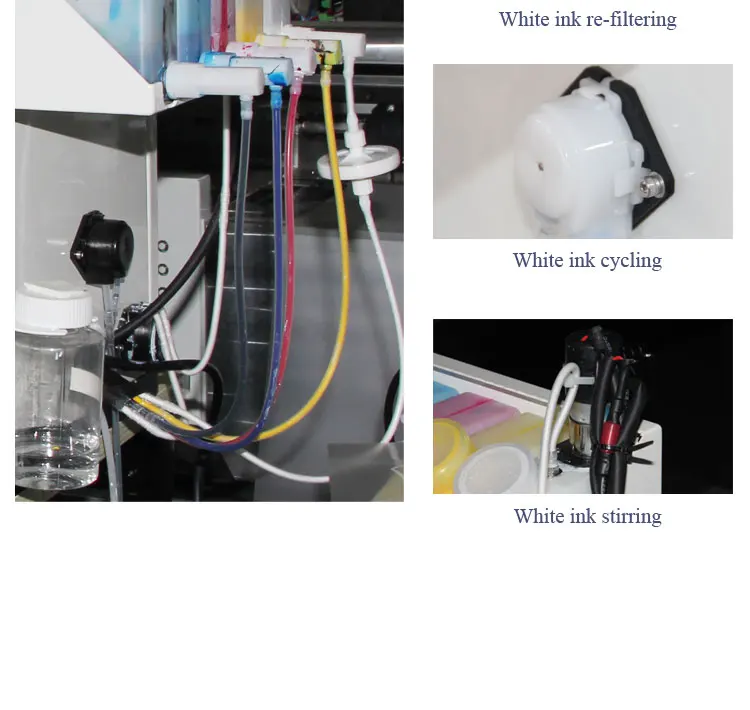

3. How does the white ink stirring/circulation system work and why is it important?

The printer has an automatic white-ink stirring/circulation system that keeps white pigment evenly suspended to prevent settling and clogging. This ensures consistent white coverage and reduces maintenance related to pigment separation.

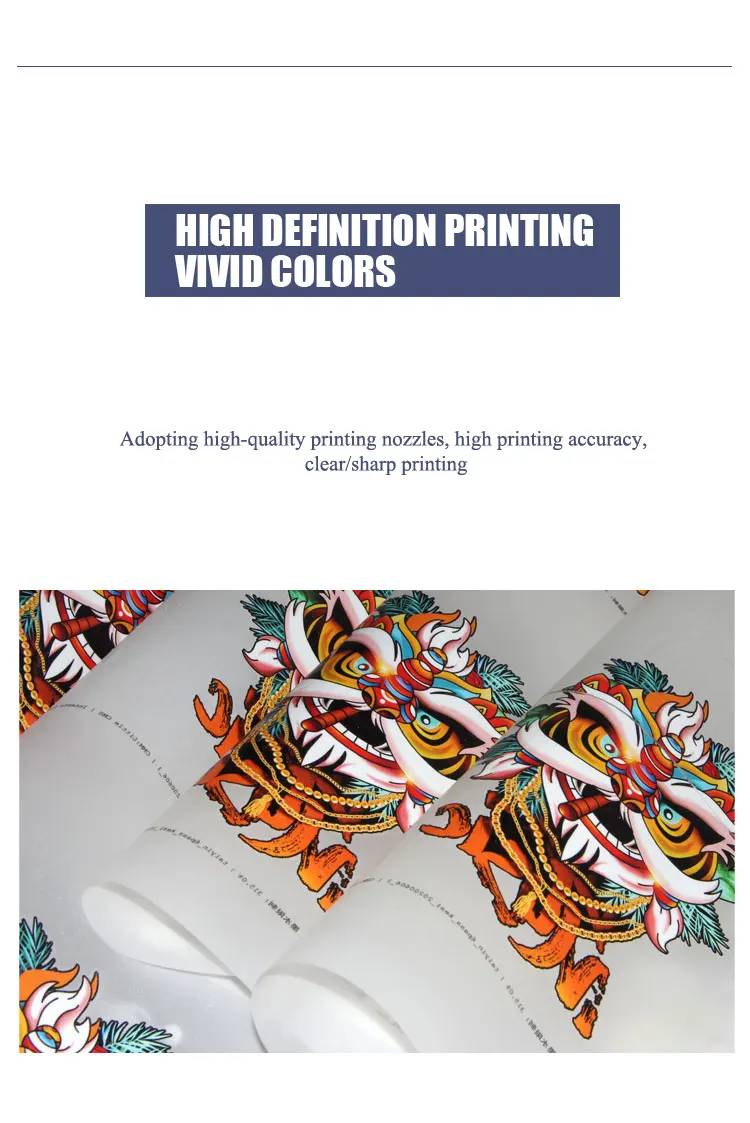

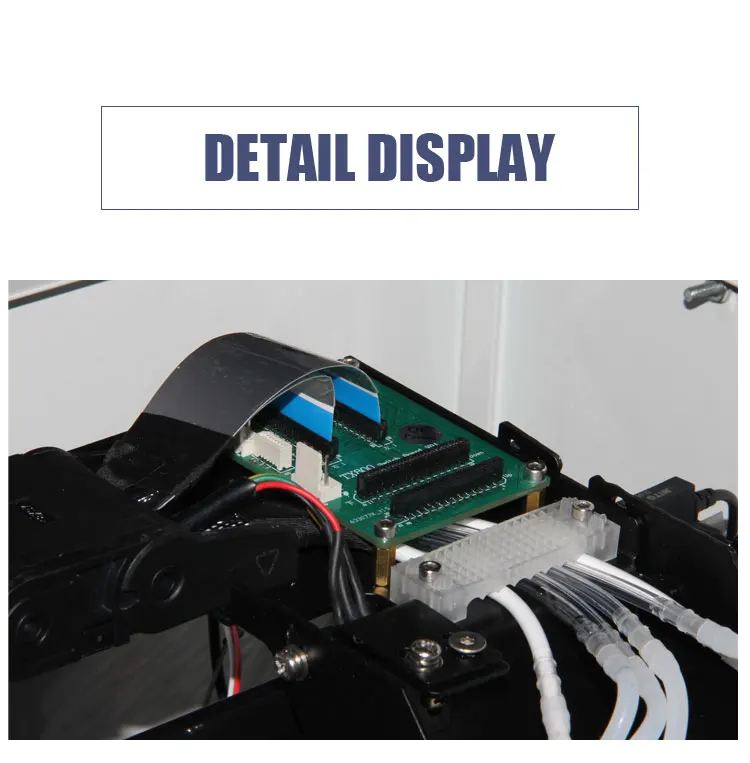

4. Which printhead does the TX800 use and what are the quality benefits?

It uses the TX800 printhead, which delivers precise droplet placement for sharp details and accurate color and white ink printing, producing high-quality, vibrant prints ideal for DTF transfers.

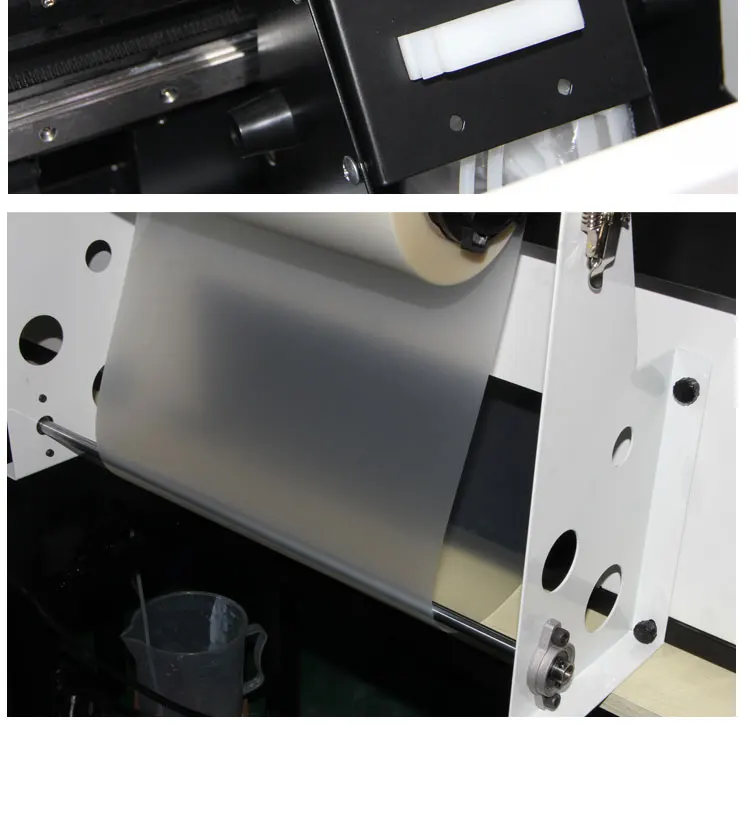

5. What media is the printer designed to work with?

The 3ALPS TX800 is designed specifically for printing onto DTF PET film for subsequent transfer to textiles and other substrates. For other media, check compatibility with your supplier or contact 3ALPS support.

6. Does the printer require manual intervention or is it automated?

The TX800 is described as full-automatic, reducing the need for manual intervention. Features such as continuous ink supply and automatic white ink stirring improve workflow efficiency, though occasional maintenance is still required.

7. What software and operating system are supported?

The printer uses Acrorip RIP software for color management and print preparation. The unit is listed as suitable for Windows; check with your vendor for specific supported Windows versions and 32/64-bit compatibility.

8. What are the power requirements?

The printer supports 110V or 220V power configurations. Confirm the correct voltage model for your region when purchasing.

9. What environmental conditions are recommended for operation?

Recommended operating conditions are temperature 15–30°C and relative humidity 40–60%. Maintaining these conditions helps ensure print stability and ink performance.

10. Is suction supported and adjustable?

Yes. The printer supports suction to hold media in place, and the suction power is adjustable to accommodate different film types and thicknesses.

11. How do I maintain and prevent nozzle clogs, especially for white ink?

Use the automatic stirring and circulation to minimize settling. Run regular head cleaning cycles as recommended by the manual, perform daily nozzle checks if used heavily, and follow prescribed storage and use procedures for white ink. For persistent clogging, follow the troubleshooting steps in the user manual or contact support.

12. What are the printer dimensions and is it suitable for desktop use?

The printer measures 800 x 330 x 290 mm (excluding the ink cartridge part). Its compact design is intended for desktop use in small workspaces.

13. Can I print directly onto garments or only on DTF film?

The TX800 is designed for printing on DTF PET film for transfers. Direct-to-garment printing typically requires different equipment and pre-treatment; consult 3ALPS or your vendor if you want to explore direct fabric printing options.

14. What should I do if prints show banding or color inconsistency?

Common fixes include running a printhead cleaning, checking nozzle health, verifying proper ink levels and circulation (especially white ink), confirming correct RIP settings and color profiles, and ensuring the substrate is secured by the suction system. If problems persist, contact technical support with sample prints and error logs.

15. Is there warranty and technical support available?

Warranty and after-sales support vary by seller and region. Check the warranty terms provided at purchase and contact your vendor or 3ALPS support for service, spare parts, and technical assistance.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading