B21, China Town Mall, Midrand

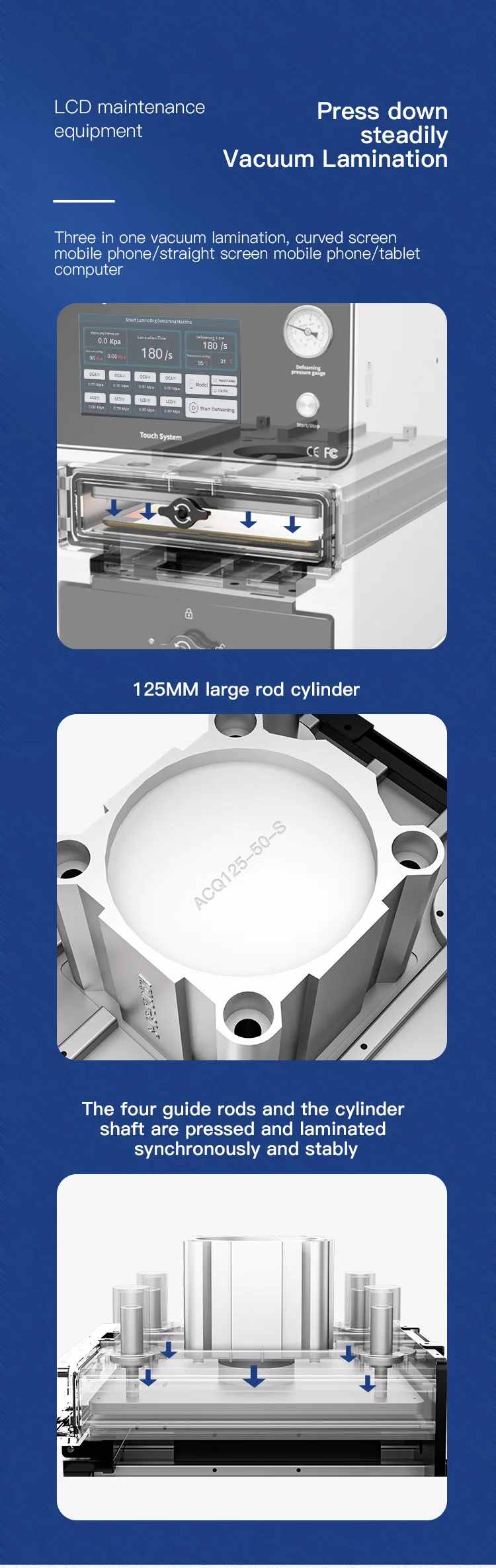

TBK-208C 15 Screen Refurbishing Machine

- Section : Machinery

- Category : Engineering & Construction Machinery

- SKU : 1600642981573

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 05 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the TBK-208C 15 Screen Refurbishing Machine used for?

It is designed for refurbishing LCD screens — removing scratches, restoring clarity and repairing screens for electronics repair shops and technicians.

2. What are the machine's main specifications (size, weight, power)?

Product dimensions: 410 × 310 × 420 mm. Package size: 440 × 340 × 450 mm. Listed power: 500 W. The spec sheet shows a net weight of 37.4 kg and a listed weight of 50 kg — please confirm gross vs. net weight with the vendor.

3. What screen sizes and thicknesses does the working cabin support?

The working cabin measures 240 × 320 × 50 mm, so it accommodates screens up to approximately that footprint and up to 50 mm in thickness. For larger screens, check with the manufacturer.

4. Is the TBK-208C suitable for OLED or other non-LCD screens?

The unit is specifically designed for LCD screen refurbishing. Compatibility with OLED, AMOLED or other display types is not guaranteed — contact the manufacturer or supplier before attempting non-LCD repairs.

5. How noisy is the machine during operation?

The specified noise level ranges from 1–50 dB, meaning it operates at a low noise level suitable for most repair-shop environments.

6. What core components ensure reliability and performance?

The machine is equipped with a PLC control system and a quality motor to provide stable, repeatable operation and reliable refurbishing performance.

7. How many screens can be refurbished per day?

Throughput depends on screen size, damage level and operator skill. The machine is described as high-efficiency, but exact pieces-per-day will vary — run time studies at your shop will give the best estimate.

8. What power supply or voltage is required?

The specification lists power consumption at 500 W but does not list voltage. Check the product label or user manual, or ask the seller for required voltage and plug type for your region.

9. What regular maintenance does the TBK-208C require?

General maintenance includes keeping the working cabin and external surfaces clean, checking and tightening mechanical fasteners, inspecting wiring and connectors, and having worn parts (motors/drive components) serviced or replaced per the manual. Follow the manufacturer's maintenance schedule.

10. Are replacement parts and consumables available?

The listing does not detail spare parts. Contact the manufacturer or authorized dealer to order replacement components, consumables and to confirm lead times.

11. Does the machine come with accessories, tools or a user manual?

Accessories and documentation are not specified in the product description. Verify the included items with the seller prior to purchase and ask for an English user manual if needed.

12. What safety precautions should operators follow?

Operators should read the user manual, use appropriate PPE (gloves/eye protection if recommended), ensure proper ventilation, keep hands clear of moving parts, and disconnect power before servicing. Follow any additional safety instructions from the manufacturer.

13. Is training required to operate the TBK-208C?

While basic operation may be straightforward, proper training is recommended to achieve consistent refurbishing quality and to operate the PLC controls safely and effectively. Ask your supplier about training or instructional materials.

14. Does the machine have certifications (CE, UL, RoHS)?

The product description does not list certifications. Ask the supplier or manufacturer for certification details and compliance documents required for your market.

15. What warranty and return policies apply to the TBK-208C?

Warranty and return information are not provided in the description. Confirm warranty length, coverage, and return terms with the seller before purchasing.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading