B21, China Town Mall, Midrand

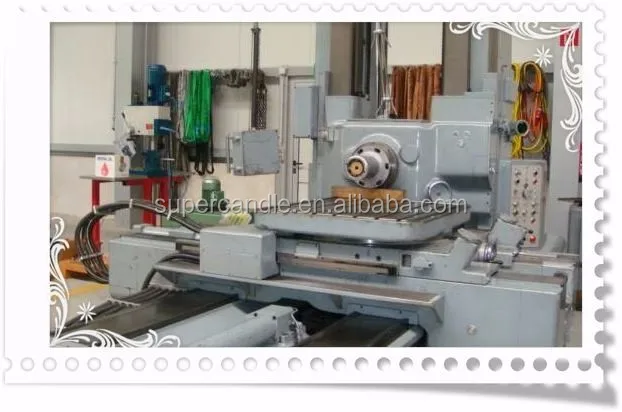

Small Semi Automatic Manual Fluted Church Candle Molds Diy Candle Making Machine Wax on 100-300 Mm Hand Crank Supercandle

- Section : Machinery

- Category : Manufacturing Machinery

- SKU : 60649647623

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 21 Mar, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the capacity of the Small Semi Automatic Manual Fluted Church Candle Molds?

The machine is available in different types based on the number of mold cavities: 60, 120, 180, 240, and 500.

2. How does the cooling system work in this candle making machine?

The machine features a built-in cooling water jacket that helps the wax cool faster, which increases the production speed.

3. What materials are used for the mold cavities?

The mold cavities are made of seamless copper tubes, ensuring durability and effective heat transfer.

4. Is it easy to operate the candle making machine?

Yes, the machine has a simple structure that is user-friendly and easy to operate and maintain.

5. Can the machine be customized for specific candle dimensions?

Yes, we offer custom builds for the fluted candle making machines according to your specific candle dimensions and shapes.

6. What kind of training is provided for new users?

We provide detailed operation manuals, as well as videos and photos to assist with operation and maintenance. Customers are also welcome to visit for hands-on training.

7. What is included in the warranty for this machine?

All machines come with a one-year warranty. Should any spare parts not be damaged due to misoperation, they are provided free of charge during the warranty period.

8. How do I maintain the candle making machine?

Maintenance involves regular cleaning, checking for wear on parts, and following the operation manual provided, which includes guidelines for upkeep.

9. What type of support is available after purchase?

We offer technical support for any questions regarding candle production and operation of the machine after purchase.

10. What materials are the piston heads made of?

The piston heads are usually made of aluminum for wear resistance, while some are made of brass for better protection.

11. How is the machine packaged for delivery?

The machine is wrapped in plastic film for dust protection and packed in a plywood case reinforced with a frame made of square steel tubes.

12. What happens if I need spare parts after the warranty period?

After the warranty period, customers will need to pay for spare parts and shipping costs.

13. Can I see a demonstration of the machine in operation?

Yes, we take photos and videos of the machine during the test run after assembly, which can be shared with customers.

14. How heavy is the candle making machine?

The machine weighs approximately 180 kg.

15. What is the production speed of this candle making machine?

The machine's water-cooled design allows for fast production speeds, although specific output rates may vary based on operational conditions.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals