B21, China Town Mall, Midrand

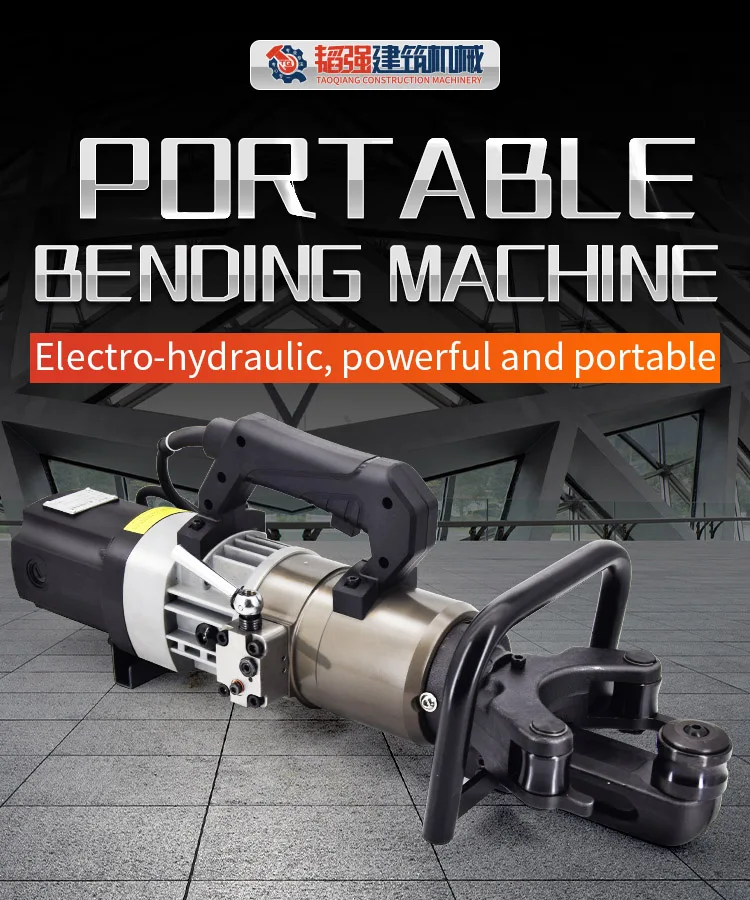

Small Hydraulic Rebar Bending Machine Portable Rebar Bending Machine

- Section : Machinery

- Category : Metal & Metallurgy Machinery

- SKU : 1600967722283

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 26 Mar, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is a Small Hydraulic Rebar Bending Machine used for?

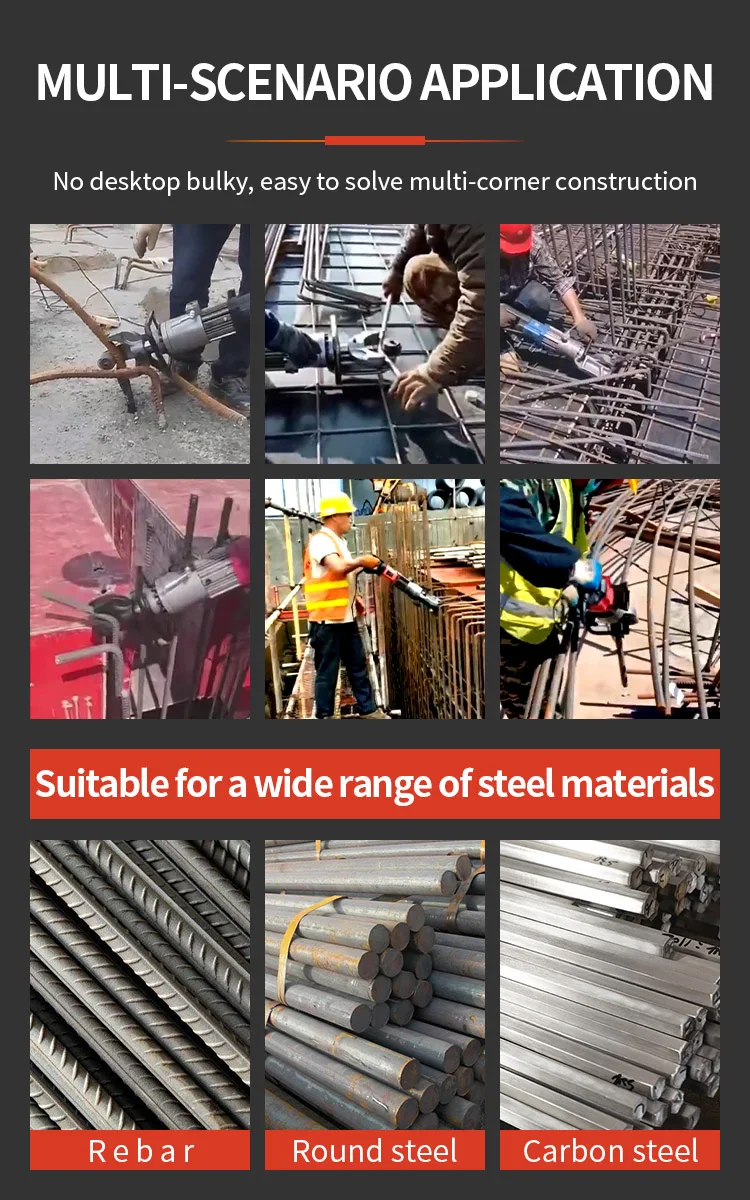

It's used to bend steel reinforcing bars (rebar) on construction sites or in workshops. The hydraulic system provides the force to form precise bends quickly and with less manual effort than manual benders.

2. What range of rebar diameters can this portable rebar bender handle?

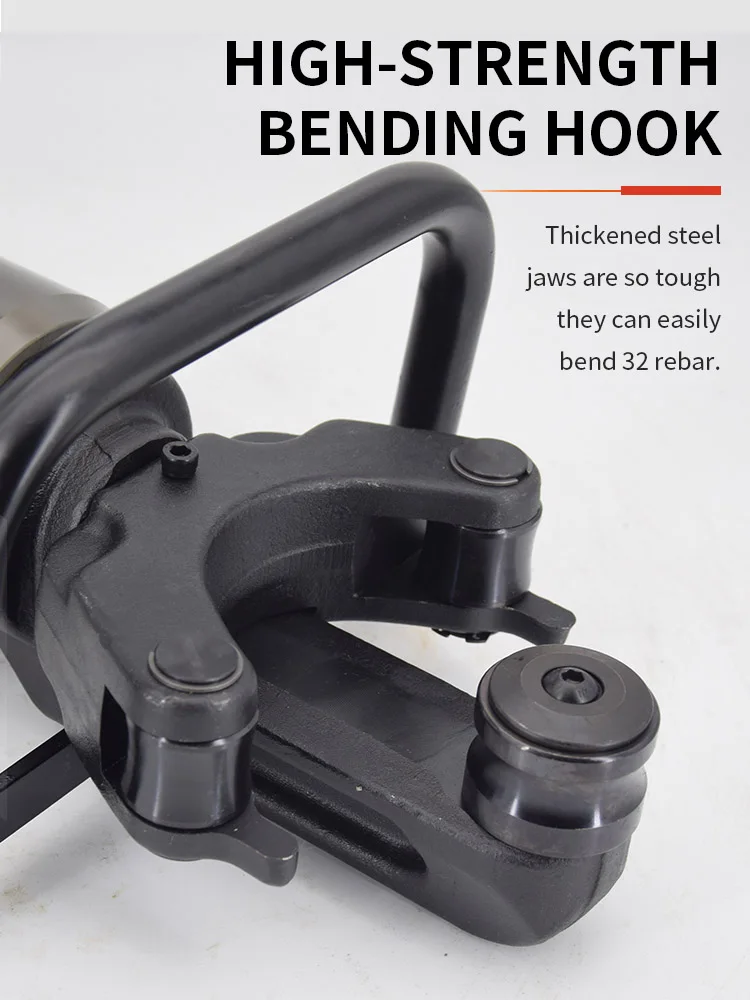

Capacity varies by model, but small portable hydraulic benders commonly handle rebar from about 6 mm up to 25–32 mm. Check the specific model's technical specifications for the exact diameter range.

3. What power source does the machine use?

Most portable hydraulic rebar benders use an electric motor-driven hydraulic pump (single-phase or three-phase). Some models offer petrol/diesel engine or battery-powered pump options for remote sites. Verify the variant when ordering.

4. What bending angles can the machine achieve?

These machines typically provide adjustable bending from 0° up to 180°, with stops or angle gauges for repeatable bends. Exact angle control and preset options depend on the model.

5. How many operators are needed to use the machine?

Most portable hydraulic rebar benders are designed for single-operator use, though an assistant may help with handling long or heavy bars for safety and accuracy.

6. Is the machine easy to transport between job sites?

Yes. Portable models are compact and often include carry handles or wheels. Weight varies by configuration (commonly from around 40 kg to over 100 kg), so check the weight and lifting requirements for your model.

7. How fast does the machine bend rebar?

Bending speed depends on rebar diameter and hydraulic pump capacity. Typical cycle times range from a few seconds to around 10 seconds per bend. Heavy diameters require longer cycle times.

8. Are bending dies/interchangeable rollers included?

Most machines come with a standard set of dies to cover common rebar sizes. Additional or replacement dies can usually be ordered separately to support other diameters or special profiles.

9. What safety features does the machine have?

Common safety features include emergency stop, protective guards/shields around moving parts, overload protection on the hydraulic system, and secure clamping to prevent slippage. Always follow the operator manual and use personal protective equipment.

10. What maintenance is required for a hydraulic rebar bender?

Routine maintenance includes checking and topping up hydraulic oil, inspecting hoses and fittings for leaks, cleaning debris from the machine, lubricating pivot points, and replacing worn dies or seals. Follow the manufacturer's maintenance schedule.

11. How accurate and repeatable are the bends?

Hydraulic control combined with mechanical angle stops or digital angle settings provides consistent and repeatable bends. Accuracy depends on setup, die selection, and operator technique.

12. What warranties and after-sales support are available?

Warranties vary by manufacturer but commonly include 12 months for parts and workmanship. Many suppliers offer spare parts, technical support, and repair services—confirm warranty length and support options before purchase.

13. Does the machine have certifications or compliance marks?

Portable rebar benders from reputable manufacturers often carry CE, ISO, or other regional certifications. Check the product listing or ask the supplier for certification documents if required for your project or region.

14. How do I order spare parts or replacement dies?

Contact the supplier or manufacturer with your machine model and serial number. Provide the part description or part number if available. Many suppliers keep common dies and wear parts in stock for quick shipment.

15. What should I consider when choosing a portable hydraulic rebar bending machine?

Key factors include the maximum rebar diameter you need to bend, available power source at job sites, portability (weight and wheels), bending angle control, the availability of dies, safety features, warranty and service network, and overall budget.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading