B21, China Town Mall, Midrand

Slaughterhouse automatic cattle slaughter line equipment

- Section : Machinery

- Category : Meat Processing Machinery

- SKU : 62195786974

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 05 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

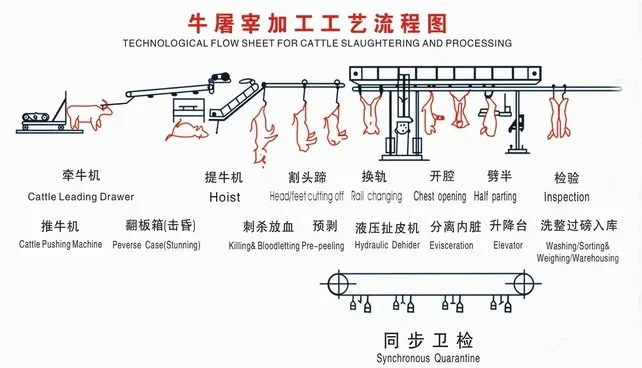

1. What types of equipment are included in the slaughterhouse automatic cattle slaughter line?

The equipment includes slaughtering equipment, cutting equipment, refrigeratory equipment, air conditioning equipment, cold storage insulation and cold storage doors, ventilation equipment, water supply equipment, sewage treatment equipment, stainless steel equipment, hot water supply equipment, video monitoring equipment, and quality tracing equipment.

2. How does the Halal Killing Box ensure safety for the operator?

The Halal Killing Box is designed to safely turn the cattle over for halal killing, minimizing the risk of injury to the operator and reducing harm to the cattle body.

3. What is the purpose of the Cattle Dehiding Machine?

The Cattle Dehiding Machine is used to remove the cattle skin downwards, ensuring complete skin removal with minimal meat loss and is equipped with a hydraulic system for stable operation.

4. What features does the Carcass Dressing Line offer?

The Carcass Dressing Line conveys cattle carcasses through various processing stages, featuring adjustable speed, a high degree of automation, and labor-saving capabilities.

5. How does the Pneumatic Elevating Platform work?

The Pneumatic Elevating Platform allows operators to move up and down with a stable pneumatic-driven mechanism, controlled by a foot pedal to avoid contamination.

6. What is the Synchronous Inspection System used for?

The Synchronous Inspection System conveys carcasses and viscera for inspection, reducing labor intensity and providing automatic cleaning and disinfection of hooks and trays.

7. How does the Automatic Carcass Washing Machine function?

The Automatic Carcass Washing Machine uses an auto-induction system to start spraying when a carcass enters, ensuring efficient cleaning while saving water.

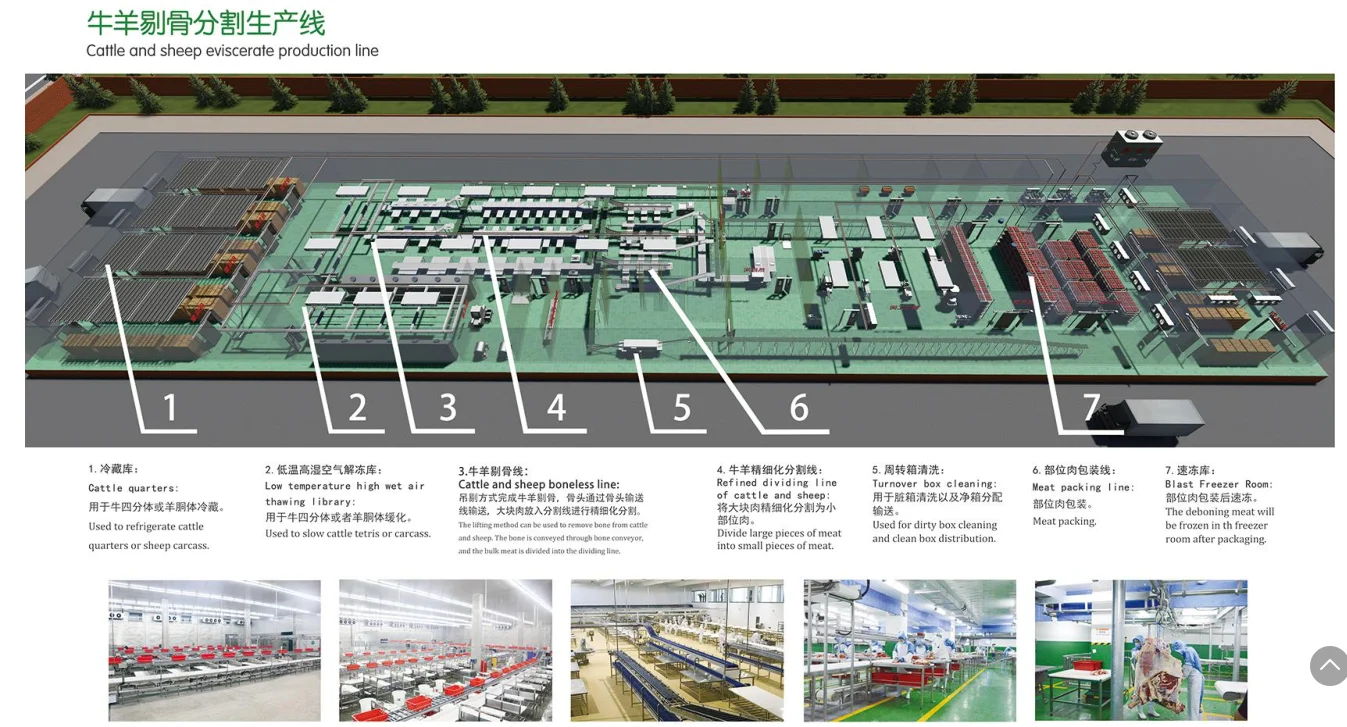

8. What materials are used in the Cutting and Deboning Line?

The Cutting and Deboning Line is composed of stainless steel and plastic components that meet food safety requirements for easy washing and maintenance.

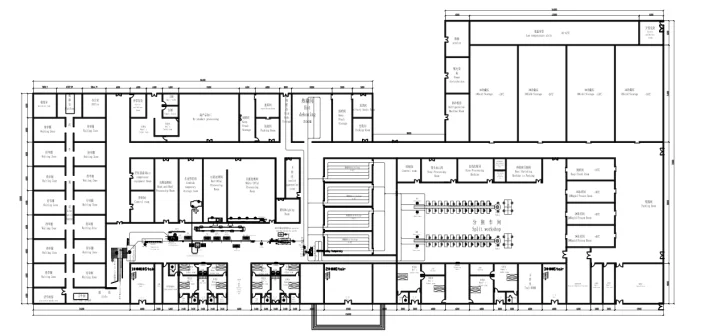

9. Can the equipment be customized based on production capacity?

Yes, the entire production line can be designed and deployed based on different production capacities to meet specific operational needs.

10. What types of refrigeration systems are available with this equipment?

The refrigeration systems included can vary based on the specific equipment configuration, ensuring optimal cooling and storage conditions for meat products.

11. Is training provided for operating the equipment?

Yes, training is typically provided to ensure operators are familiar with the equipment's functions, safety procedures, and maintenance requirements.

12. What are the maintenance requirements for this equipment?

Regular maintenance includes cleaning, checking hydraulic systems, and inspecting conveyor speeds to ensure optimal performance and longevity of the equipment.

13. Is the equipment compliant with food safety standards?

Yes, all equipment is designed to comply with food safety standards, ensuring hygienic processing and handling of meat products.

14. What safety features are included in the design?

Safety features include operator guardrails, anti-slip standing boards, and automatic cleaning systems to maintain a safe working environment.

15. What is the expected lifespan of this equipment?

The expected lifespan can vary based on usage and maintenance, but typically these types of equipment are designed for long-term durability and efficiency.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading