B21, China Town Mall, Midrand

slanty snack bar twin screw extruder corn chips snacks food making machine snack food extrusion machine

- Section : Machinery

- Category : Food & Beverage Machinery

- SKU : 60730007720

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 22 Mar, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What types of snacks can be produced using the slanty snack bar twin screw extruder?

The extruder can produce a variety of snacks including corn chips, rice snacks, and other snacks made from ingredients like millets, wheat, oats, and barley.

2. What is the production capacity of the snack food extrusion machine?

The production capacity varies by model, ranging from 100 kg/h to 10 tons/h, depending on the specific extruder model chosen.

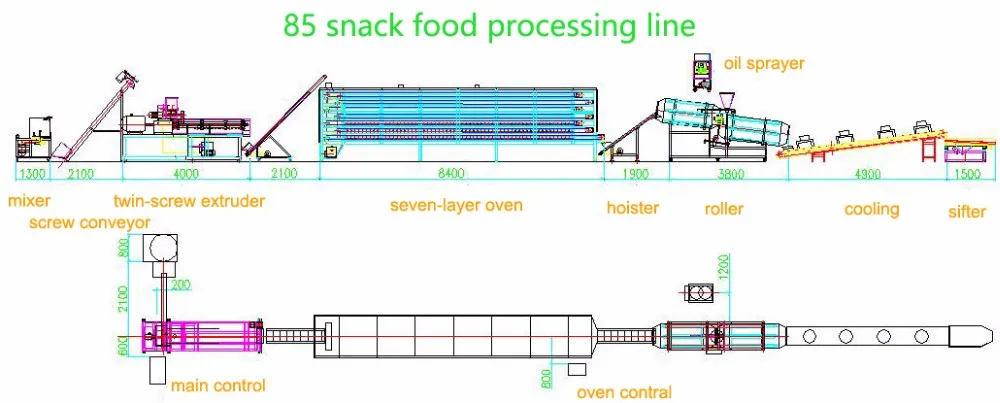

3. How does the snack food extrusion process work?

The process involves several steps: grinding, mixing, extruding, drying, flavoring, cooling, and packaging. Each step is automated for efficiency.

4. What materials are needed to operate the extruder?

You will need raw materials such as corn, rice, millets, wheat, oats, and barley in powder (flour) or grits form.

5. Is the slanty snack bar twin screw extruder easy to operate?

Yes, the machine is designed for easy operation with a high level of automation, minimizing the need for manual intervention.

6. What are the main features of the machine?

Key features include a simple linear structure for easy installation, high automation, advanced components, and a pollution-free operation.

7. Can the layout of the production line be customized?

Yes, our engineers can design a layout drawing based on your factory dimensions to optimize the production line setup.

8. What types of mixers are available for use with the extruder?

You can choose from single axle and double shaft mixers, with various motor capacities available to suit your production needs.

9. What is the warranty on the slanty snack bar twin screw extruder?

Warranty details may vary, but typically, the machine comes with a manufacturer warranty that covers defects and malfunctions under normal use.

10. How long does it take to set up the machine?

Setup time can vary based on installation complexity, but typically it can be completed within a few days with proper guidance.

11. What is the maintenance requirement for the extruder?

Regular maintenance includes cleaning, lubricating moving parts, and checking for wear and tear to ensure optimal performance.

12. Can the machine handle different flavors and seasonings?

Yes, the flavoring machine can be used to apply various oils and flavors to the snacks during the production process.

13. What are the dimensions of the machines?

Dimensions vary by model; for instance, the DSE6574 measures 17m x 1.2m x 2.2m, while the DSE8513 measures 28m x 3.5m x 4.3m.

14. Is training provided for operating the machine?

Yes, we offer training for operators to ensure they are fully capable of running and maintaining the machine effectively.

15. What kind of after-sales support is available?

We provide comprehensive after-sales support, including troubleshooting, spare parts availability, and technical assistance.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals