B21, China Town Mall, Midrand

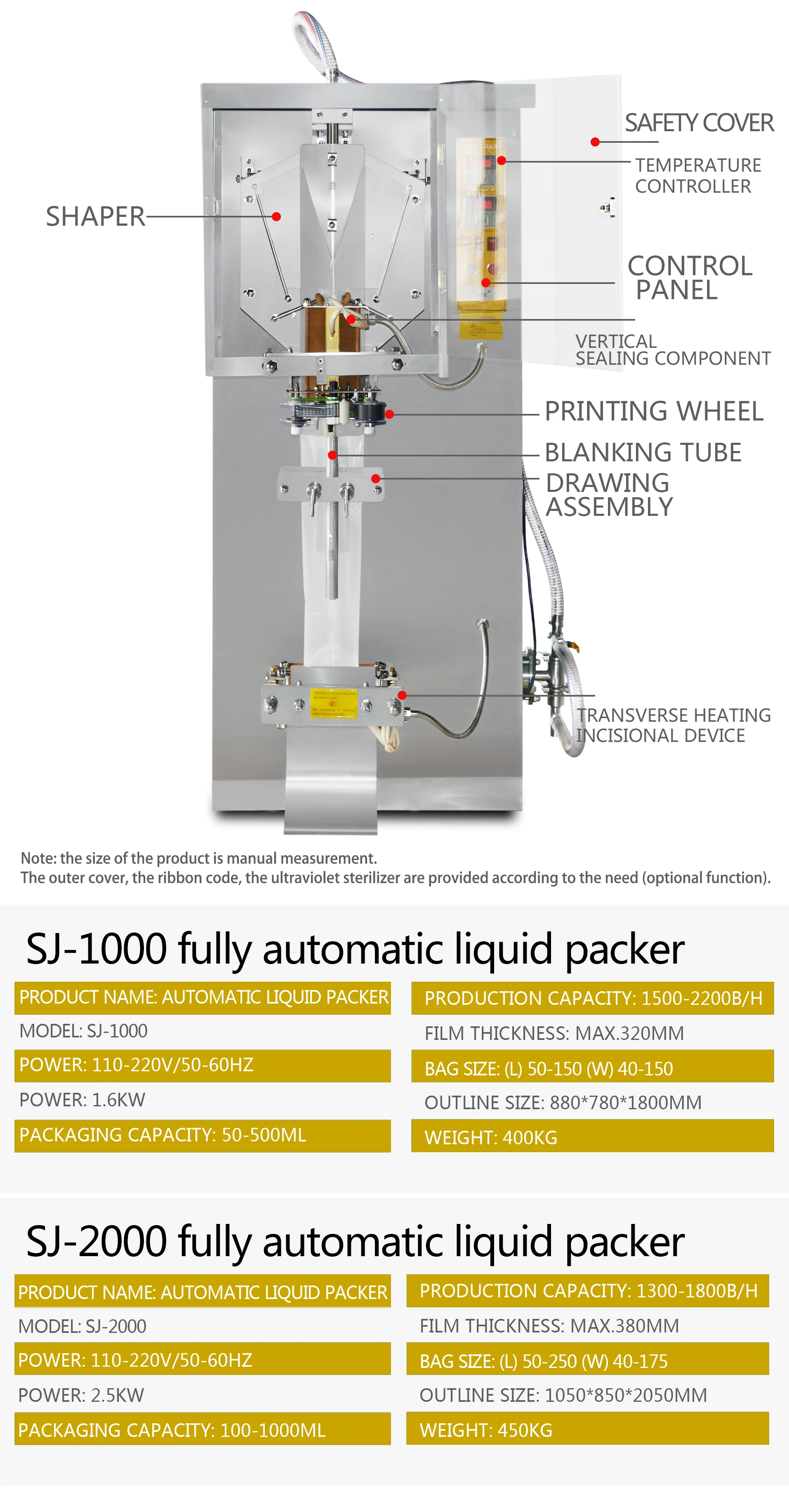

SJ-1000 Automatic Liquid Packing Machine

- Section : Machinery

- Category : Multi-Function Packaging Machines

- SKU : 60251280814

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 05 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

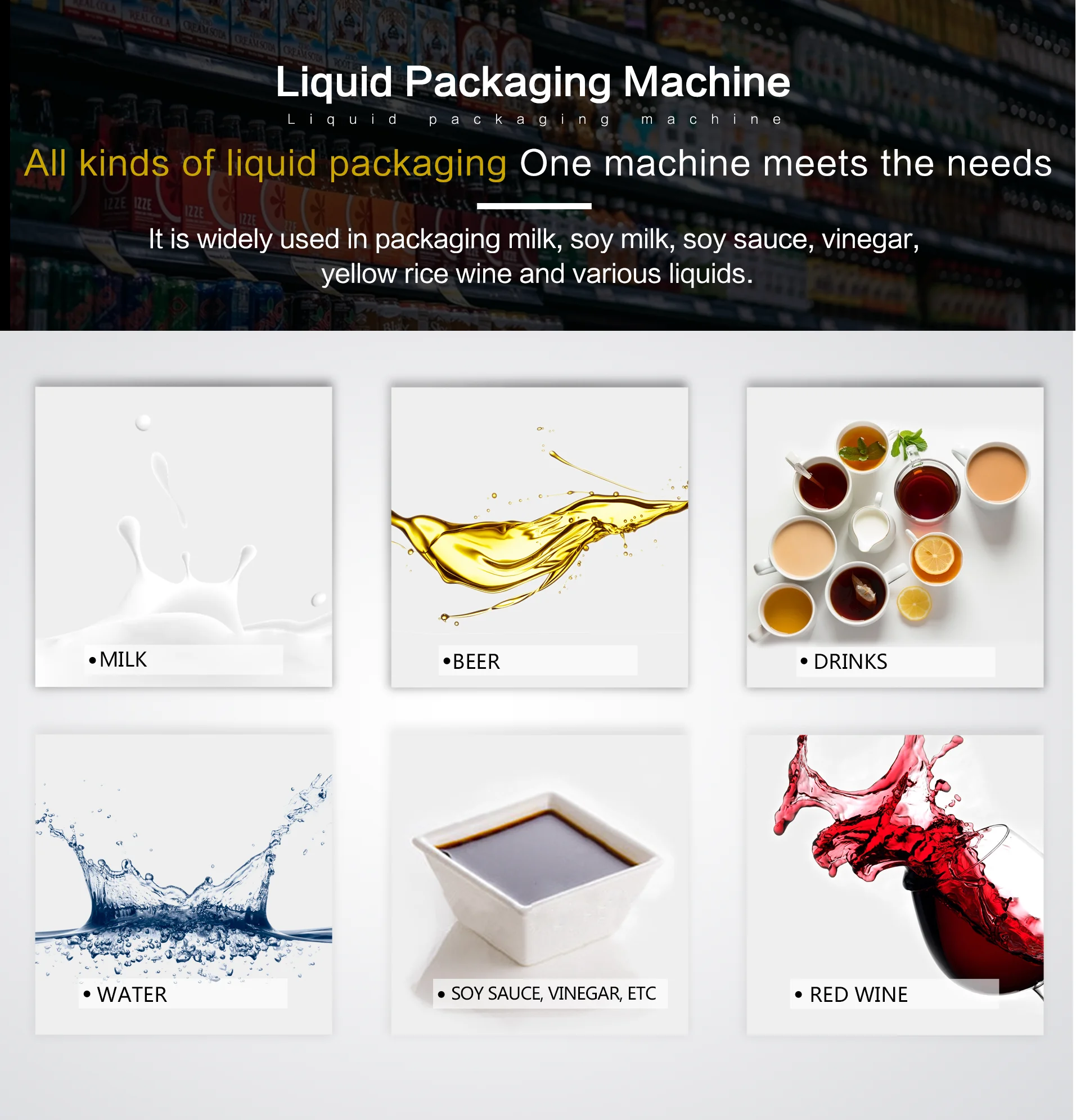

1. What liquids can the SJ-1000 Automatic Liquid Packing Machine handle?

The SJ-1000 is designed for a wide range of liquids including milk, soybean milk, sauces, vinegar, yellow wine and many other beverages. For high-viscosity or particulate-filled liquids (chunks or seeds) please consult the supplier for necessary pump/nozzle adjustments.

2. What is the pack size and production speed of the SJ-1000?

The machine supports pack volumes from approximately 50–500 ml and runs at about 1,500–2,100 packs (bottles/pouches) per hour, depending on product properties and film specifications.

3. What are the electrical requirements and power consumption?

Electrical requirements are 220–380 V, 50–60 Hz, with a rated power of 1.8 kW. Confirm whether your site supply is single-phase or three-phase with your vendor before installation.

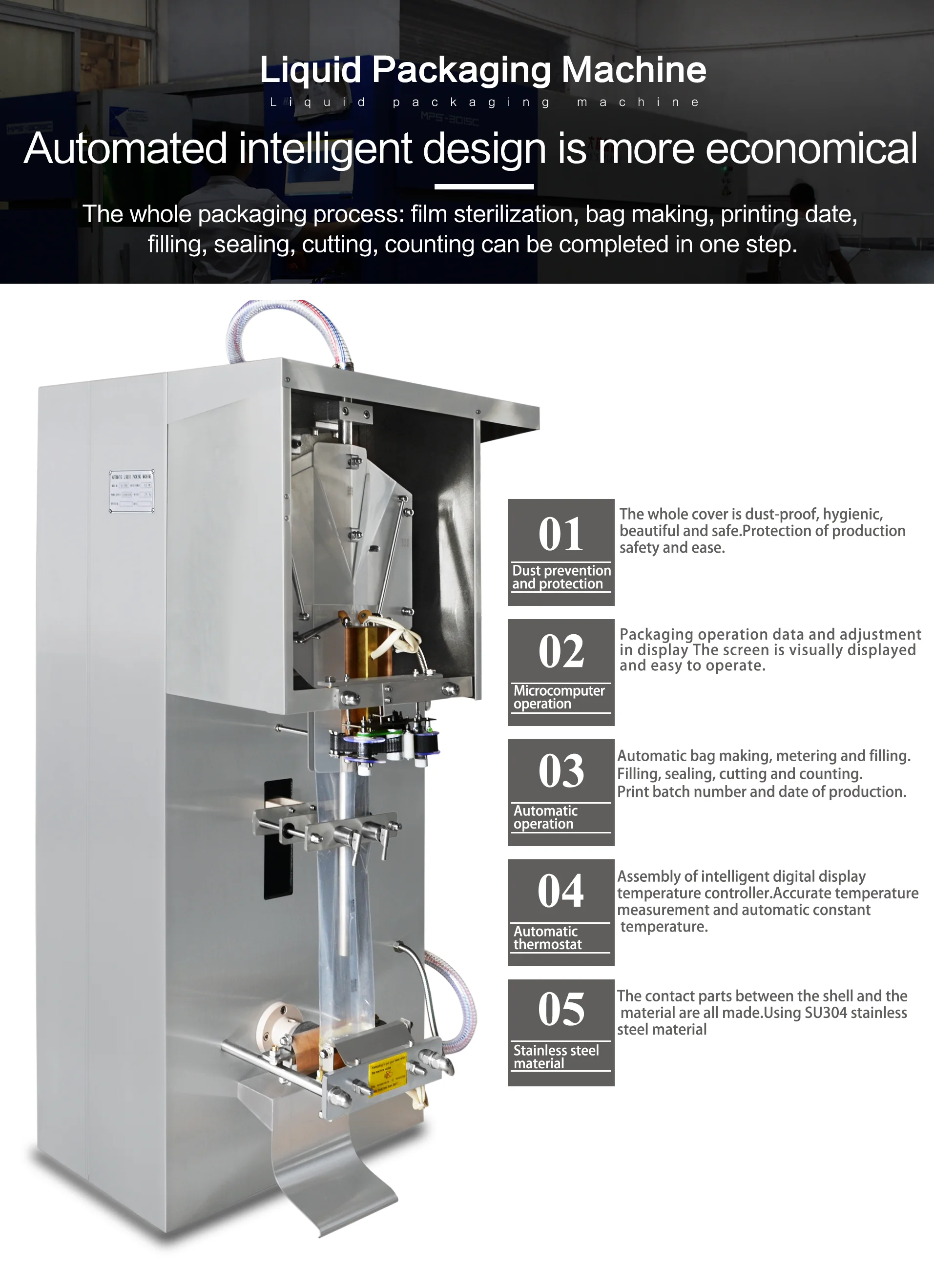

4. What automated functions does the machine perform?

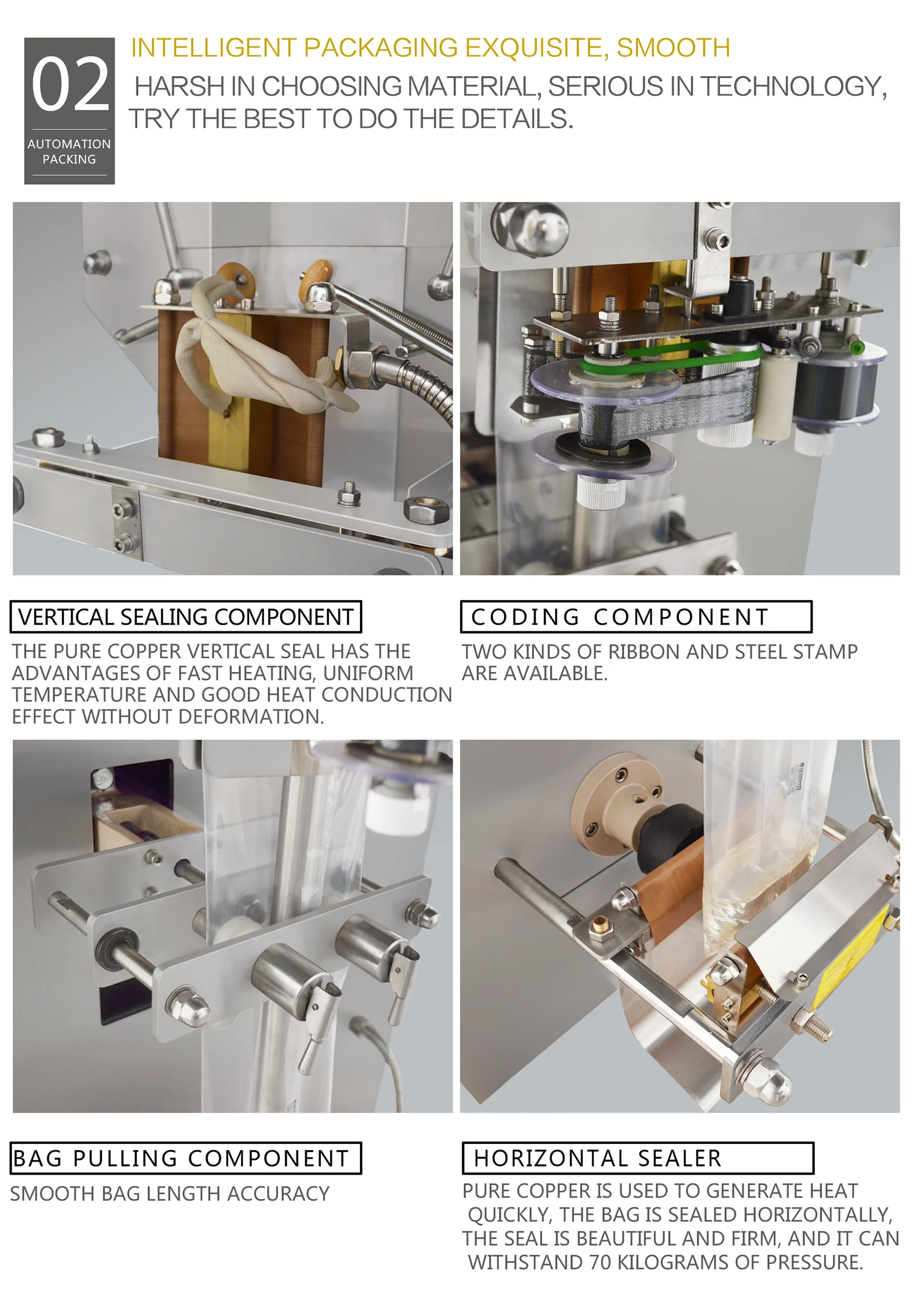

The SJ-1000 automates bag formation, ultraviolet (UV) sterilization (optional), date printing, quantitative filling, heat-sealing, enveloping/cutting and counting — providing an end-to-end packaging cycle.

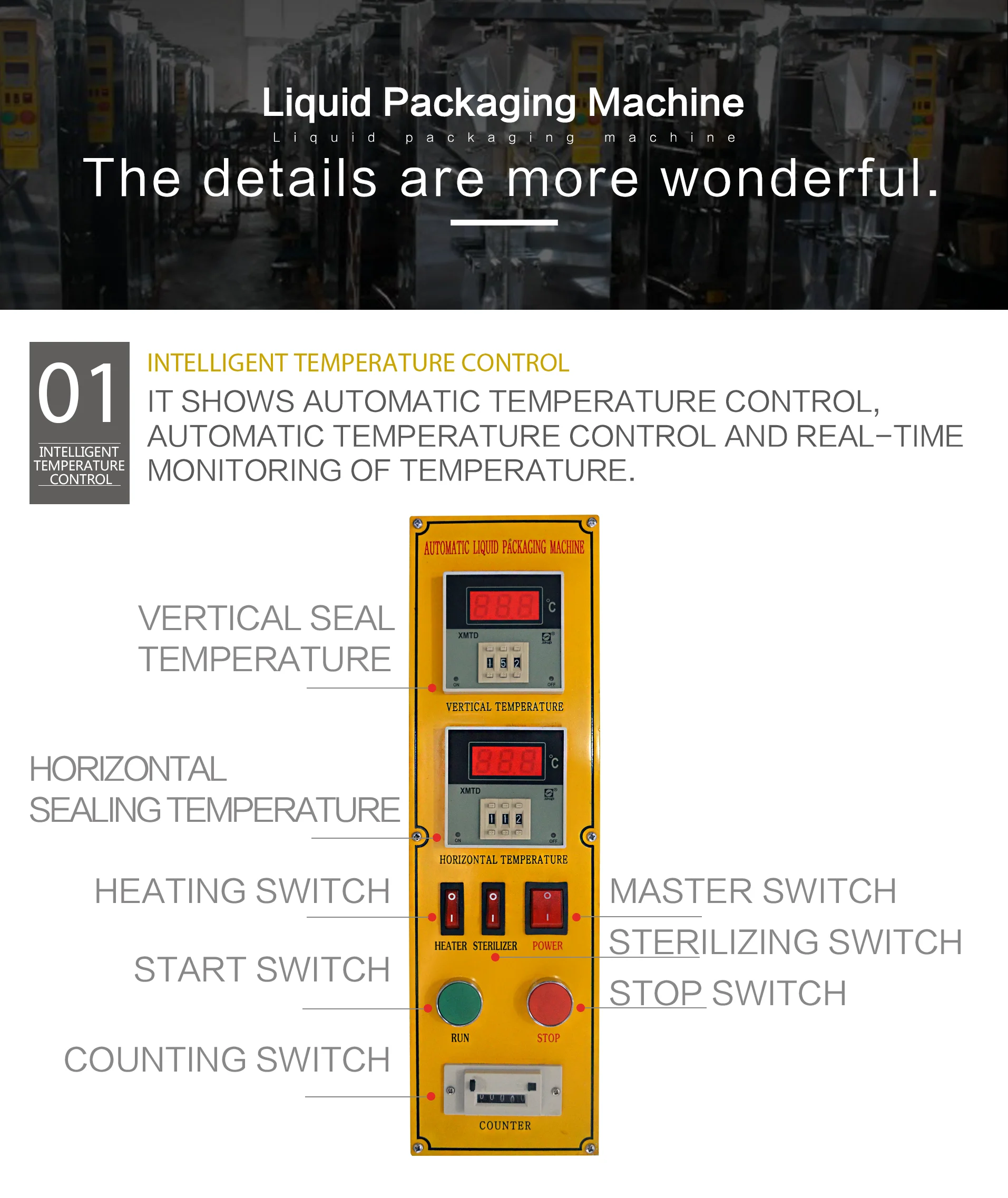

5. How is sealing quality ensured?

Sealing temperature is automatically regulated by the machine to maintain consistent, repeatable heat-seals. Sealing parameters can be adjusted for different film materials and product types.

6. What sanitary features does the machine include?

The machine is constructed with a stainless-steel shell for hygienic operation. Optional UV sterilizer and a glass cover are available to enhance cleanliness and allow sanitized visual inspection during operation.

7. Which film types and formats are compatible?

The SJ-1000 is compatible with roll-fed flexible films commonly used for liquid pouches. Film material (PE, PET/PE laminates, etc.), thickness and width should be specified to the supplier so the machine can be set up or adjusted accordingly.

8. Can I add coding, printing or sterilization accessories?

Yes — the machine can be equipped with a ribbon coder (date/lot coder), UV sterilizer and a glass cover. Additional accessory or integration options may be available on request.

9. What are the machine dimensions and weight?

Overall dimensions are approximately 880 × 760 × 1800 mm, and the machine weight is around 370 kg.

10. What routine maintenance is required?

Regular maintenance includes cleaning the contact surfaces, checking and tightening mechanical fasteners, inspecting sealing jaws and cutters for wear, cleaning or replacing filters, and verifying sensors and pumps. Follow the manufacturer's maintenance schedule and use recommended spare parts.

11. How do I clean and sanitize the SJ-1000?

Wipe down stainless-steel surfaces with food-safe cleaners and disinfectants; clean product-contact parts according to the product’s hygiene requirements. If using the optional UV sterilizer, follow safety procedures to avoid direct UV exposure. Consult the operator manual for detailed cleaning/CIP instructions.

12. What common troubleshooting steps should I follow for sealing or filling issues?

Common steps: verify correct film type and tension, check sealing temperature and pressure, ensure no foreign material on sealing jaws, confirm correct pump/nozzle calibration for filling volume, inspect sensors and coding alignment, and check for film path obstructions or worn cutters.

13. Can the SJ-1000 be integrated into an existing production line?

Yes — the SJ-1000 can be integrated with upstream and downstream equipment such as product feed tanks, pumps, conveyors, cappers or case packers. Provide line speed and interface requirements to the supplier for integration planning.

14. What training and support are provided?

Most suppliers provide operator and maintenance training at installation, as well as user manuals and troubleshooting guides. After-sales support, spare parts and extended training packages vary by vendor — confirm details with your supplier.

15. How do I obtain spare parts, warranty and after-sales service?

Warranty terms, spare parts availability and after-sales service are provided by the manufacturer or authorized distributor. Contact the supplier or your point of purchase for specific warranty coverage, spare-parts kits and service contracts.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading