B21, China Town Mall, Midrand

Single Arm Hydraulic Press YKT-10T by KLT

- Section : Machinery

- Category : Lathe

- SKU : 11000006689933-1712846658

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 06 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the rated capacity of the Single Arm Hydraulic Press YKT-10T by KLT?

The YKT-10T is a 10-ton nominal capacity single arm hydraulic press designed for metal forming and sheet processing.

2. What are the main power and electrical requirements?

The press is equipped with a 2.2 kW motor and can be supplied for 220 V or 380 V operation. Confirm required phase (single- or three-phase) and local wiring standards with KLT before installation.

3. What are the machine dimensions and weight?

Overall dimensions are 1100 mm (L) × 960 mm (W) × 2200 mm (H). Machine weight is approximately 1.8 tonnes.

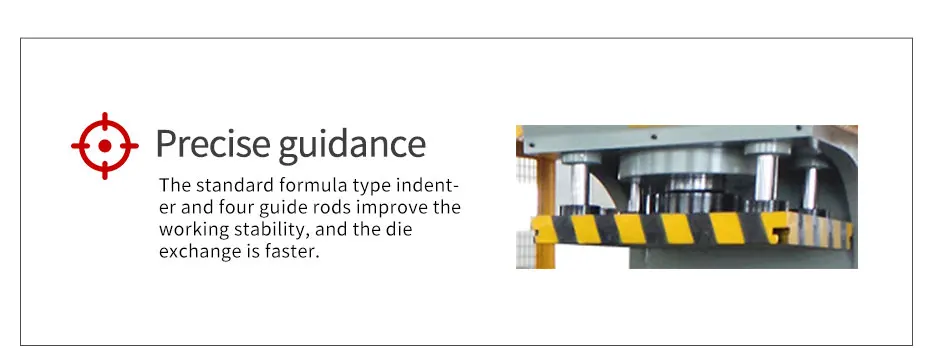

4. What is the slide stroke and tooling travel on this model?

The YKT-10T features an adjustable slide stroke of 50 mm. Verify die height and material thickness so they are compatible with the available stroke.

5. What forces does the ejector and return deliver?

The machine provides an ejector force of 100 kN and a return force of 100 kN, ensuring reliable material handling during operations.

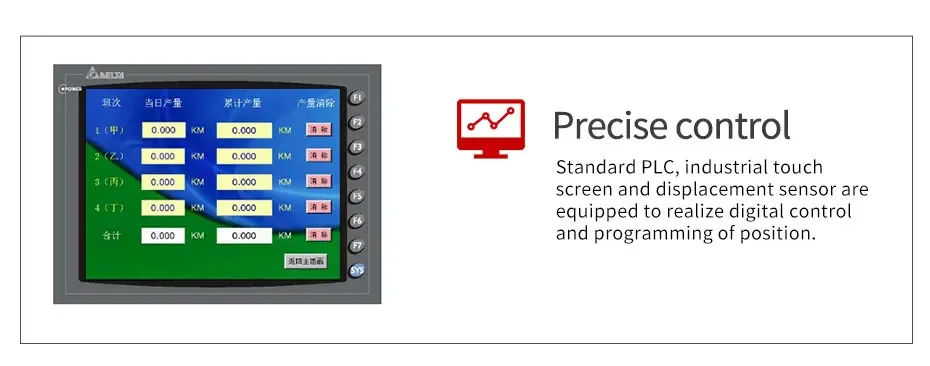

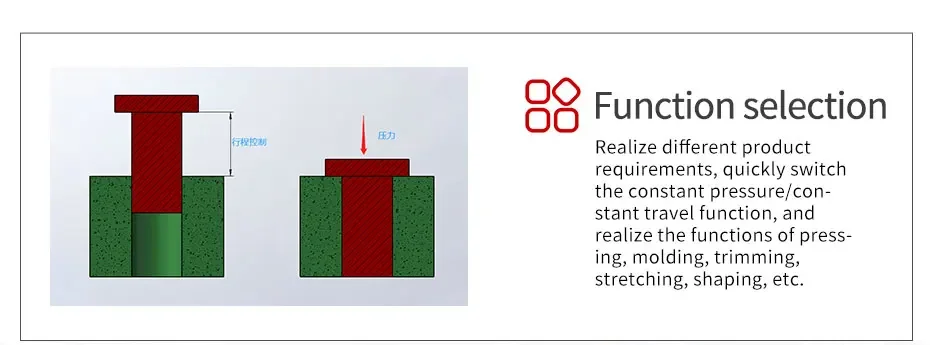

6. Which control and automation features are included?

Standard components include PLC program control, a TPC industrial touch screen (HMI), digital stroke and speed display, constant travel and constant pressure functions, and displacement sensing for precise control.

7. What safety features come with the YKT-10T?

Safety features include a photoelectric protection device, safety light curtain protection, and standard emergency stop functions. Operators must also follow local safety regulations and use appropriate PPE.

8. What industries and applications is the YKT-10T suited for?

The YKT series is suitable for metalworking across machine tools, construction machinery, electrical components, bearings, washing machines, auto and motor parts, and powder metallurgy—particularly where high automation and large-scale production are required.

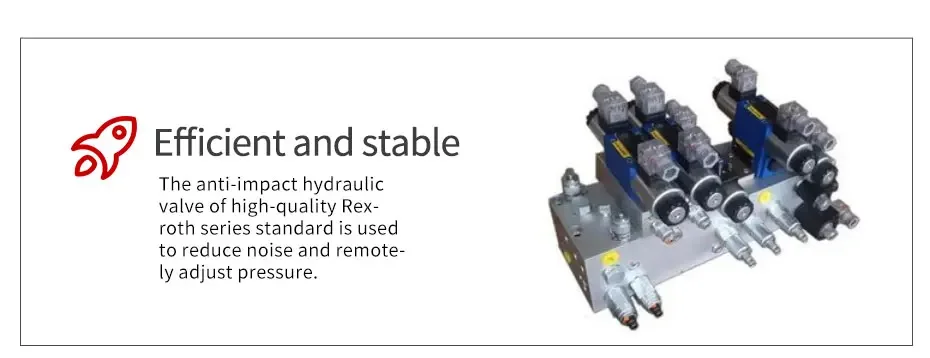

9. How energy efficient and fast is this press?

The press uses a servo system for high-speed operation and improved energy efficiency compared with traditional hydraulic drives, making it suitable for high-production environments.

10. What warranty and quality assurance are provided?

KLT provides a 2-year warranty. Each machine ships with a machinery test report and a video of the outgoing inspection to verify operation and quality before delivery.

11. Can the press be customized (color, options, accessories)?

Yes. The YKT-10T is available in customized color options. Additional accessories and configuration changes (e.g., tooling plates, special guards, or control options) can be arranged—contact KLT for quotes.

12. What installation and site requirements should I prepare for?

Provide a leveled, adequately rated floor or foundation capable of supporting ~1.8 t, appropriate electrical supply (220/380 V), proper grounding, and sufficient workspace clearance around the 1100×960 mm footprint and 2200 mm height. KLT can advise on detailed site requirements.

13. How should I maintain the YKT-10T for reliable operation?

Follow a regular maintenance routine: daily visual checks (hydraulics, hoses, fittings), weekly lubrication and fastener inspection, periodic hydraulic fluid and filter changes per KLT recommendations, and scheduled calibration of sensors and PLC. Keep a log of maintenance and address any leaks or unusual noises promptly.

14. Are spare parts and technical support available?

Yes. KLT supplies core spare parts (bearings, pumps, motors, PLC components, pressure vessels) and technical support. Contact KLT or an authorized distributor for part numbers, lead times, and service agreements.

15. What should I check to ensure my dies and tooling are compatible with this press?

Confirm that die dimensions and required forming travel fit within the 50 mm slide stroke and the machine's throat/clearance envelope. Also verify table size and clamping arrangement against your tooling. For specialized tooling or complex dies, consult KLT engineering for compatibility and recommended setup.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading