B21, China Town Mall, Midrand

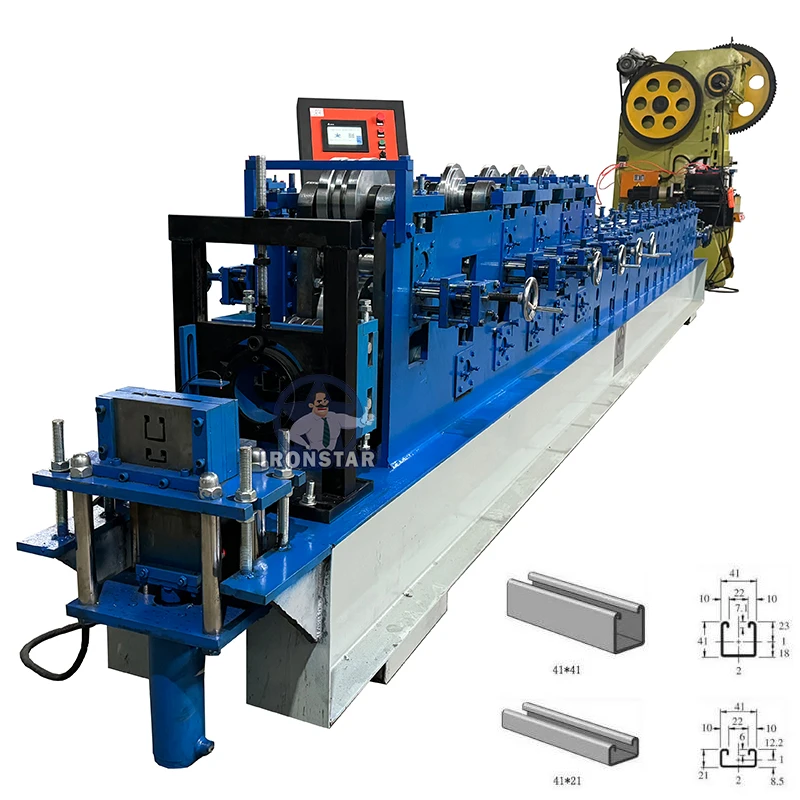

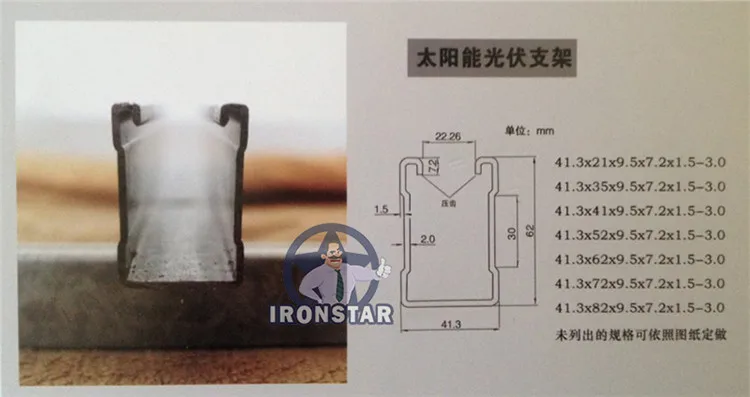

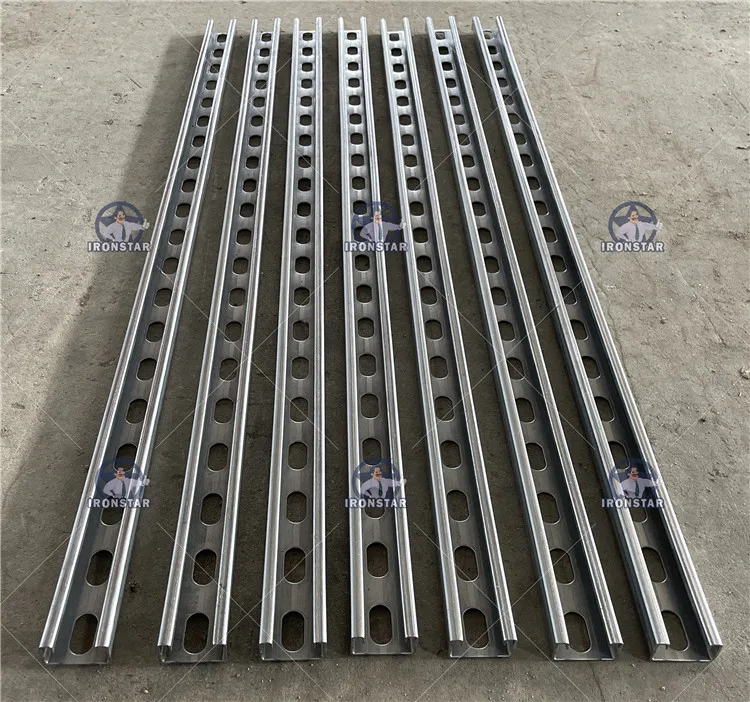

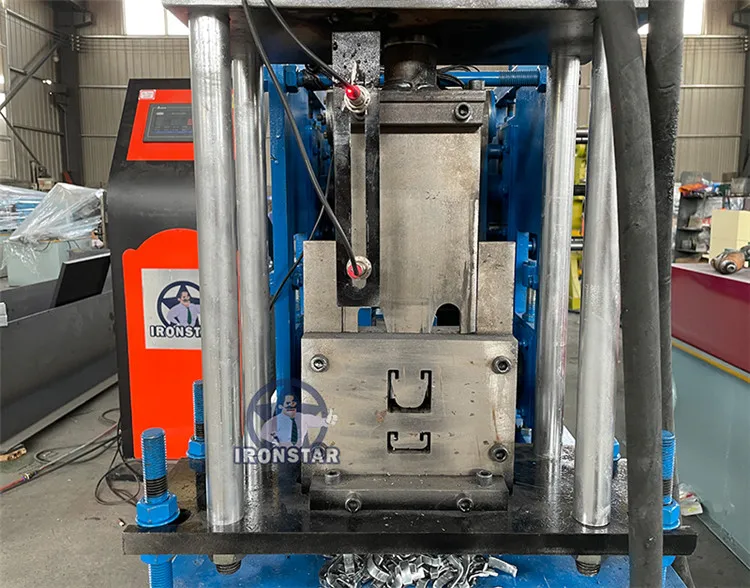

Rail Turnkey Solar Panel Production Line And Stand Alone Power Rooftop System Machine On PLAIN Channel41 X 41

- Section : Electrical & Tools

- Category : Solar Production Lines

- SKU : 1601146835829

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 05 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the production capacity of the Rail Turnkey Solar Panel Production Line?

The machine operates at a speed of 8-20 meters per minute, providing a high production capacity suitable for large-scale manufacturing demands.

2. What materials can be used with this production line?

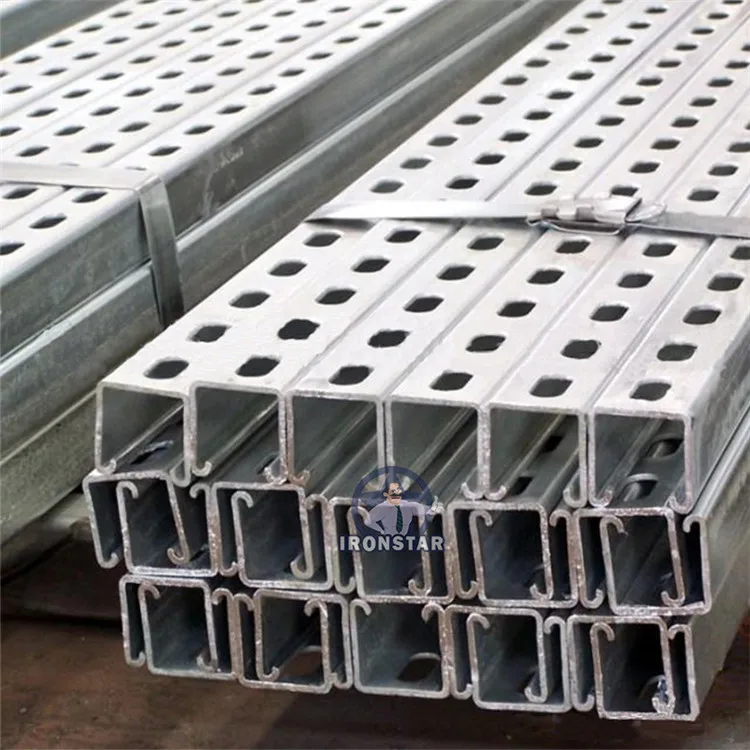

The Rail Turnkey Solar Panel Production Line is designed to work primarily with galvanized steel, ensuring durability and corrosion resistance.

3. What are the dimensions of the machine?

The machine has compact dimensions of 8.5m x 0.8m x 1m, making it suitable for various production facilities, including those with limited space.

4. How heavy is the production line?

The Rail Turnkey Solar Panel Production Line weighs approximately 4500 kg, ensuring stability and durability during operation.

5. Is the production line customizable?

Yes, the machine offers customizable options such as color and control box language to meet customer preferences and adapt to international markets.

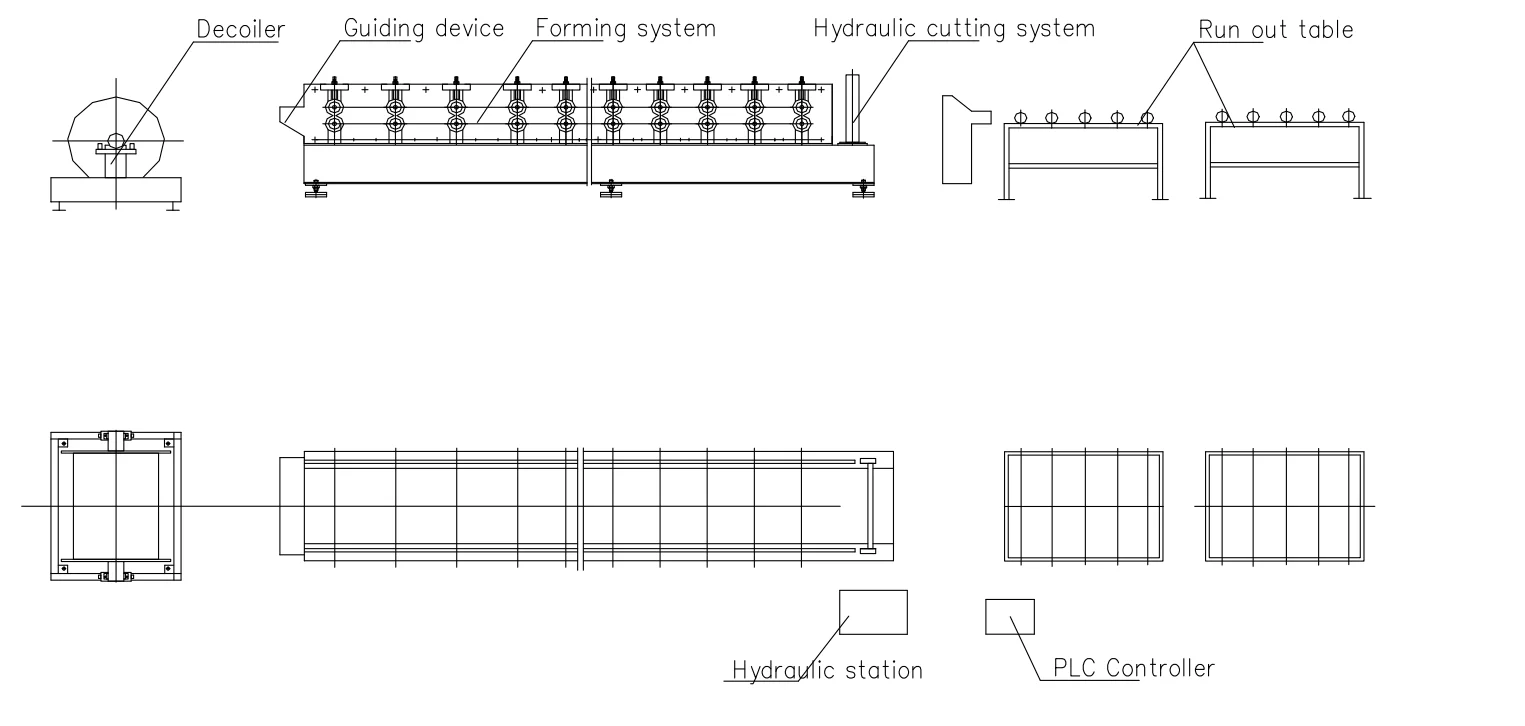

6. What type of control system does the machine use?

The production line features a DELTA PLC control system, which allows for easy monitoring and precise control of the production process.

7. What kind of warranty is provided with the machine?

The Rail Turnkey Solar Panel Production Line comes with a 3-year warranty and after-sales support to ensure reliable performance and customer satisfaction.

8. Does the machine include any inspection reports?

Yes, the machine comes with test reports and video outgoing inspections to verify its quality and performance before shipment.

9. What is the cutting technology used in the machine?

The production line is equipped with high-grade Cr12 cutting blades and rollers, ensuring clean and precise cutting of materials for optimal performance.

10. Can this machine be used for residential solar panel production?

Yes, the Rail Turnkey Solar Panel Production Line is designed for manufacturing solar panels suitable for both residential and commercial use.

11. How does the machine contribute to eco-friendly production?

The production line supports the manufacturing of solar panels, which contributes to sustainable energy practices and environmentally-friendly solutions in the solar industry.

12. What is the power consumption of the machine?

The main power consumption of the machine is 7.5 kW, with an additional pump power of 4 kW, with a voltage of 380V/50HZ.

13. What additional equipment is included in the production line setup?

The working flow includes a decoiler, roll forming machine, PLC control box, hydraulic cutter, and a run-out table.

14. Is training provided for operating the machine?

Typically, training is provided as part of the installation process to ensure that operators can effectively use the machine.

15. What are the maintenance requirements for the production line?

The machine is designed for minimal maintenance due to its high-quality components, but regular checks on the control system and cutting blades are recommended.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading