B21, China Town Mall, Midrand

QTY4-25A Automatic Block Forming Machine

- Section : Machinery

- Category : Brick Making Machinery

- SKU : 1600495501360

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 04 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What types of concrete products can the QTY4-25A Automatic Block Forming Machine produce?

The QTY4-25A can produce solid, hollow, and honeycomb blocks, paving stones, garden and landscaping products, grass blocks, slope blocks, and interlocking blocks.

2. What raw materials are compatible with the QTY4-25A machine?

The machine is designed to work with a variety of raw materials, including cement, gravel, river sand, tailings, coal stone, fly ash, slag, volcanic ash, and expanded perlite.

3. What is the production capacity of the QTY4-25A?

The production capacity varies by brick type. For example, it can produce up to 1,950,000 hollow bricks annually and 9,000,000 standard bricks.

4. What are the dimensions of the QTY4-25A machine?

The machine measures 3000×1950×2400 mm and has a pallet size of 850×580×40 mm.

5. How long does it take to complete a molding cycle?

The molding cycle for the QTY4-25A is between 20 to 25 seconds.

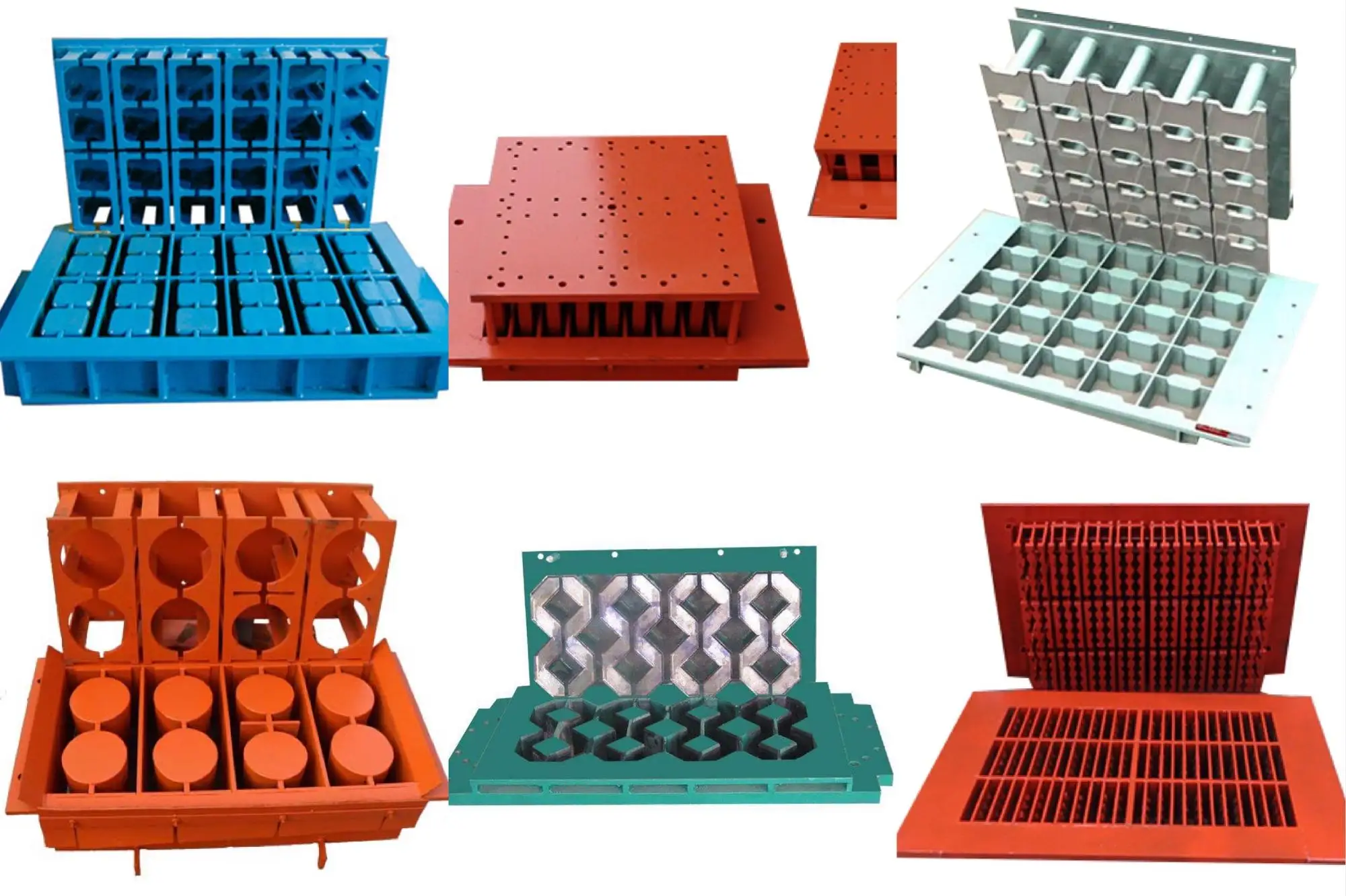

6. Is it possible to customize the molds for this machine?

Yes, the QTY4-25A offers customizable molds, allowing you to create specific brick sizes and shapes according to your needs.

7. What is the power requirement for the QTY4-25A machine?

The machine requires a power supply of 21 kW.

8. What is the weight of the QTY4-25A machine?

The total weight of the QTY4-25A machine is approximately 5 tons.

9. How does the QTY4-25A ensure the quality of the bricks produced?

The machine utilizes high-speed production with excellent vibration force, which ensures consistent brick quality during the molding process.

10. What are the executive standards followed by the QTY4-25A?

The QTY4-25A follows the GB/T8533-1998 executive standards.

11. Can the QTY4-25A be used for large-scale production?

Yes, the QTY4-25A is designed for high-efficiency and cost-effective large-scale brick production, making it ideal for businesses in the construction industry.

12. What is the vibration frequency of the QTY4-25A?

The vibration frequency of the QTY4-25A is 4200 times per minute.

13. What is the maximum exciting force of the machine?

The maximum exciting force of the QTY4-25A is 60 kN.

14. What are the typical applications of products made by the QTY4-25A?

Products made by the QTY4-25A can be used in various construction and landscaping applications, including building foundations, paving, and garden features.

15. What types of paving stones can be produced?

The machine can produce paving stones with or without surface mixtures, catering to different aesthetic and functional requirements.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading