B21, China Town Mall, Midrand

Portable Handheld PP PET Strapping Tool Pneumatic Machine Banding Wrapping

- Section : Machinery

- Category : Wrapping Machines

- SKU : 1600935082188

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 03 Feb, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the Portable Handheld PP PET Strapping Tool Pneumatic Machine Banding Wrapping?

A handheld pneumatic strapping tool designed to tension, seal and cut polypropylene (PP) and polyester (PET) plastic straps for packaging and bundling. It uses compressed air to deliver consistent tension and quick sealing for industrial and warehouse applications.

2. Which strap materials and sizes does this tool support?

The tool is built for standard PP and PET straps. Exact supported strap widths and thicknesses vary by model, so check the product specifications for the compatible strap width (e.g., 9–19 mm ranges are common) and strap thickness.

3. What kind of power source does the tool require?

It is pneumatic and requires a compressed air supply. Typical operating pressure is around 0.6–0.8 MPa (6–8 bar), but you should confirm the required pressure and air flow for your specific model.

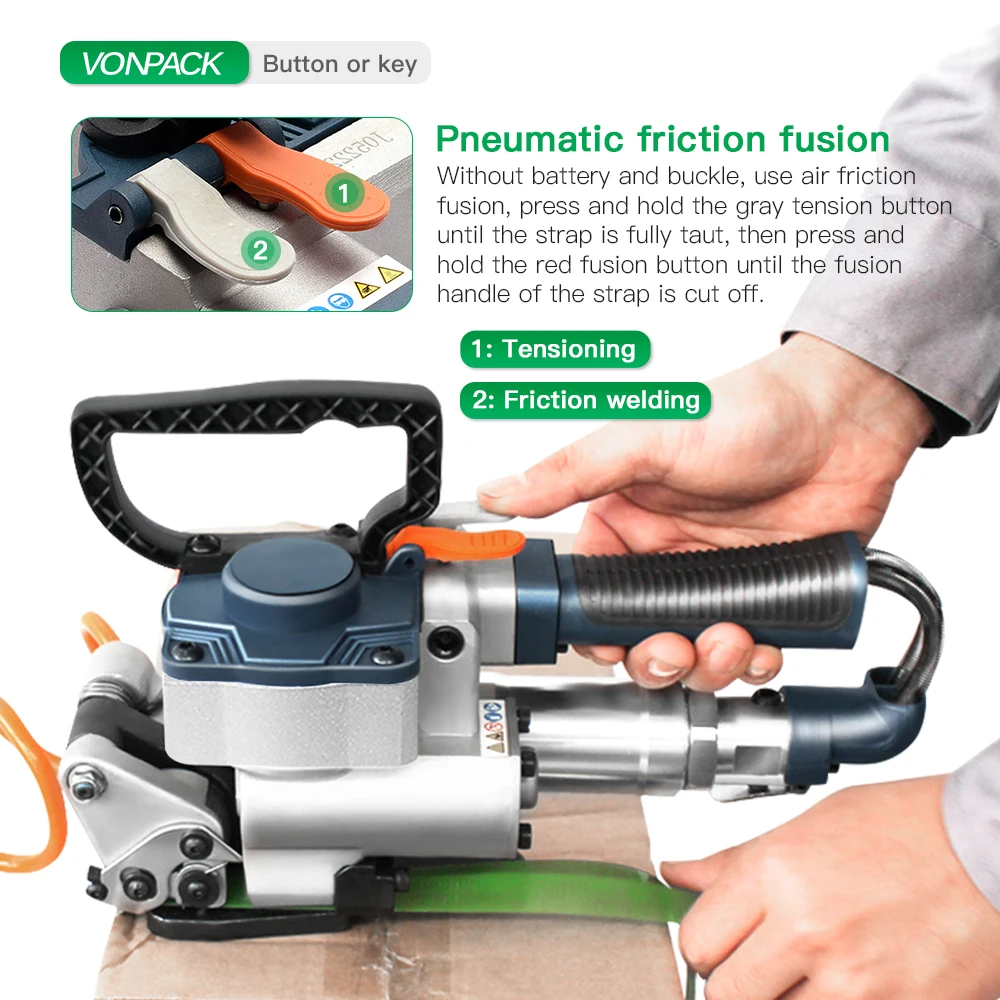

4. How does the sealing/joining mechanism work?

Many pneumatic PP/PET handheld tools use friction or heat-welding to fuse strap ends, though some models may use metal seals. The exact sealing method depends on the model—refer to the product specs for confirmation.

5. How do I operate the tool (basic steps)?

General steps: (1) Feed strap around the package and into the tool, (2) engage the tension function to tighten to the desired tension, (3) activate the sealing/welding function, (4) the tool will cut the excess strap and release. Always follow the user manual for model-specific procedures.

6. What are the main advantages of using a pneumatic handheld strapping tool?

Advantages include faster cycle times, consistent and adjustable tension, reduced operator fatigue compared with manual strapping, greater sealing reliability, and suitability for medium- to heavy-duty applications.

7. What maintenance does the tool require?

Regular maintenance includes cleaning strap debris from the tool, lubricating moving parts per the manual, checking and replacing worn blades/sealing elements, draining the compressor/filter regulator, and inspecting pneumatic fittings and hoses.

8. What safety precautions should I follow?

Wear appropriate PPE (safety glasses, gloves), keep hands clear of the sealing/cutting area, disconnect air supply before maintenance, ensure straps are positioned correctly, and follow manufacturer safety guidelines and training.

9. Is a compressor included with the tool?

Most listings for handheld pneumatic strapping tools do not include an air compressor. You will typically need to provide a compatible compressor, hoses and appropriate fittings unless the package explicitly states otherwise.

10. What accessories and spare parts are commonly needed?

Common accessories and spares include cutting blades, sealing pads/blocks, replacement springs, tension wheels, air hoses, fittings, and replacement seals or welding elements. Availability depends on the model.

11. Which industries or applications is this tool best for?

Common uses include palletizing and shipping, logistics, carton and bundle strapping, construction materials, timber and board bundling, and manufacturing lines where fast, repeatable strapping is needed.

12. What are common troubleshooting tips if the tool isn’t performing properly?

If seals fail or welds are weak, check air pressure, strap type, and wear on sealing elements. If tension is low, verify compressor supply and inspect tensioning parts. If the tool won’t operate, check the air supply, filters, and for blocked or damaged hoses. Refer to the troubleshooting section of the manual.

13. How fast is the strapping cycle?

Cycle time varies by model and operator, but pneumatic handheld tools typically complete tensioning, sealing and cutting in a matter of seconds—often around 1–3 seconds per strap under ideal conditions.

14. Can I use the tool outdoors or in cold/wet environments?

The tool can be used outdoors if protected from extreme weather; ensure your compressor and air lines are suitable for outdoor use and consider an air dryer or filter to remove moisture. Avoid exposing the tool to heavy rain, freezing conditions, or corrosive environments unless the model is rated for such use.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals