B21, China Town Mall, Midrand

PF1210 - LTMG Impact Crusher Machine

- Section : Machinery

- Category : Mining Machinery

- SKU : 1600889337659

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 11 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the maximum throughput (capacity) of the PF1210 - LTMG Impact Crusher Machine?

The PF1210 has a maximum capacity of up to 800 t/h, designed for high-volume crushing in large-scale operations.

2. What is the maximum feed size the PF1210 can handle?

The crusher accepts a maximum feeding size of up to ≤1000 mm (for materials with anti-crushing compressive strength ≤300 MPa and moisture below about 8–10%).

3. Which materials and industries is this impact crusher suitable for?

It is suitable for crushing stones, rocks, ores and other medium-hard to soft materials. Typical applications include mining, building-stone production, highways, railways, cement, energy, chemical and manufacturing plants.

4. What is the machine's weight and how does that affect installation and transport?

The PF1210 has a rugged build weighing approximately 15,000 kg. Due to its weight and dimensions, heavy transport equipment and appropriate lifting gear are required; professional installation support is recommended.

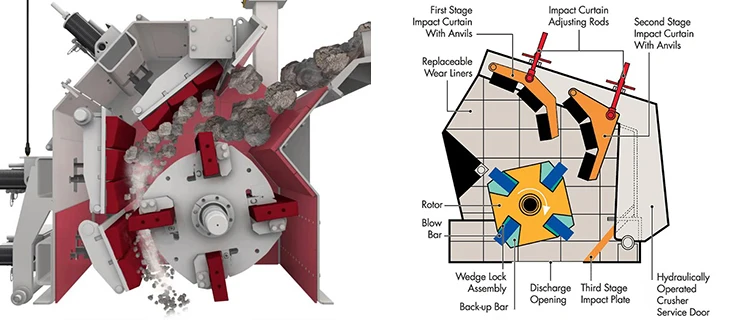

5. What type of crusher design does the PF1210 use?

The PF1210 uses an impact (coal hammer) crusher design with a rotor and blow-bars/hammer elements. It features a three-chamber configuration for improved crushing performance and particle size control.

6. What safety features are included with the PF1210?

The machine is designed to meet high safety standards, including guarded moving parts, emergency stop provisions, safe access points for maintenance, and design elements that reduce the risk of blockages. Final safety scope may vary by configuration and local regulations.

7. Is installation assistance provided?

Yes. Installation is provided under the guidance of an engineer to ensure correct setup, alignment and safe commissioning.

8. What warranty and after-sales support are available?

The PF1210 comes with a 1-year warranty. LTMG provides global availability and local service support in many regions; contact your local representative for after-sales service, spare parts and maintenance support.

9. How often do wear parts (hammers, blow bars, liners) need replacement?

Wear-part life depends on feed material hardness, abrasiveness and operating conditions. Typical replacement intervals vary widely; operators should inspect components regularly (daily visual checks, weekly detailed inspections) and replace wear parts when wear adversely affects performance or safety.

10. Can the PF1210 operate outdoors and in harsh mining environments?

Yes. The machine is built for heavy-duty use in mining and construction environments. For extreme climates or corrosive conditions, discuss protective finishes, enclosures and additional weatherproofing with your sales engineer.

11. What are the material moisture limits for efficient operation?

For optimal crushing, feed material moisture should generally be below about 8–10%. Higher moisture contents can cause clogging and reduced efficiency.

12. Are dust and noise control options available?

Yes. Standard and optional measures such as dust suppression systems (water spray, hoods), enclosures, extraction connections and acoustic enclosures or barriers can be provided or recommended depending on site requirements.

13. Does the PF1210 support hydraulic adjustment and easy maintenance?

The machine includes an improved hydraulic adjustment device (for convenient gap/setting adjustment) and design features that simplify servicing. Exact hydraulic features may vary by configuration.

14. Can the PF1210 be customized for different applications or local regulations?

Yes. Configurations, wear materials, feeding systems, drive options and environmental control packages can be adjusted to match material characteristics and local regulatory or operational requirements. Contact sales for custom options and specification sheets.

15. How do I get technical specifications, power requirements and dimensions for planning purposes?

Detailed technical data (electrical power requirements, rotor speed, overall dimensions, foundation drawings and lifting plans) are available from LTMG or your local sales engineer. Provide your site requirements and material characteristics to receive the correct specification package.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading