B21, China Town Mall, Midrand

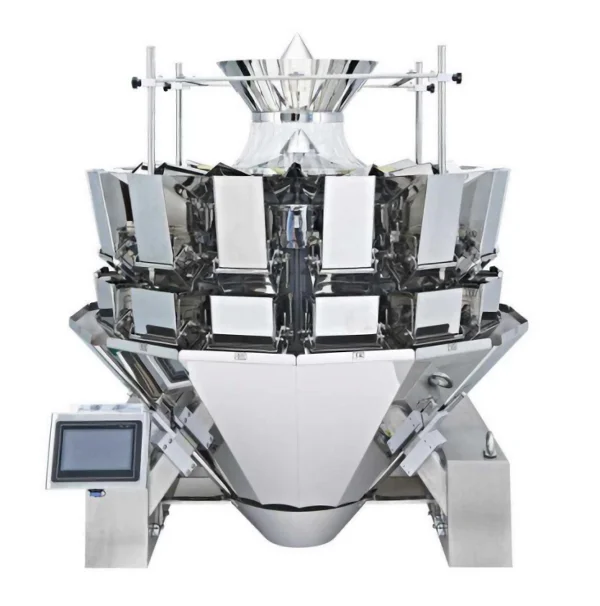

Packaging Machine For Nuts Grain Vertical Form Fill And Seal

- Section : Machinery

- Category : Multi-Function Packaging Machines

- SKU : 1601009577706

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 05 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is this machine designed to pack?

The machine is designed for vertical form-fill-seal packaging of nuts and grains, integrating weighing, bag making, filling and sealing for products like peanuts, cashews, almonds, kernels and various grains.

2. Which models are available and what are the main differences?

Two models are listed: ZD-540 and ZD-730. The primary difference is the maximum film/reel width (540 mm for ZD-540 and 730 mm for ZD-730), which allows different maximum bag widths and overall machine footprint/power/weight.

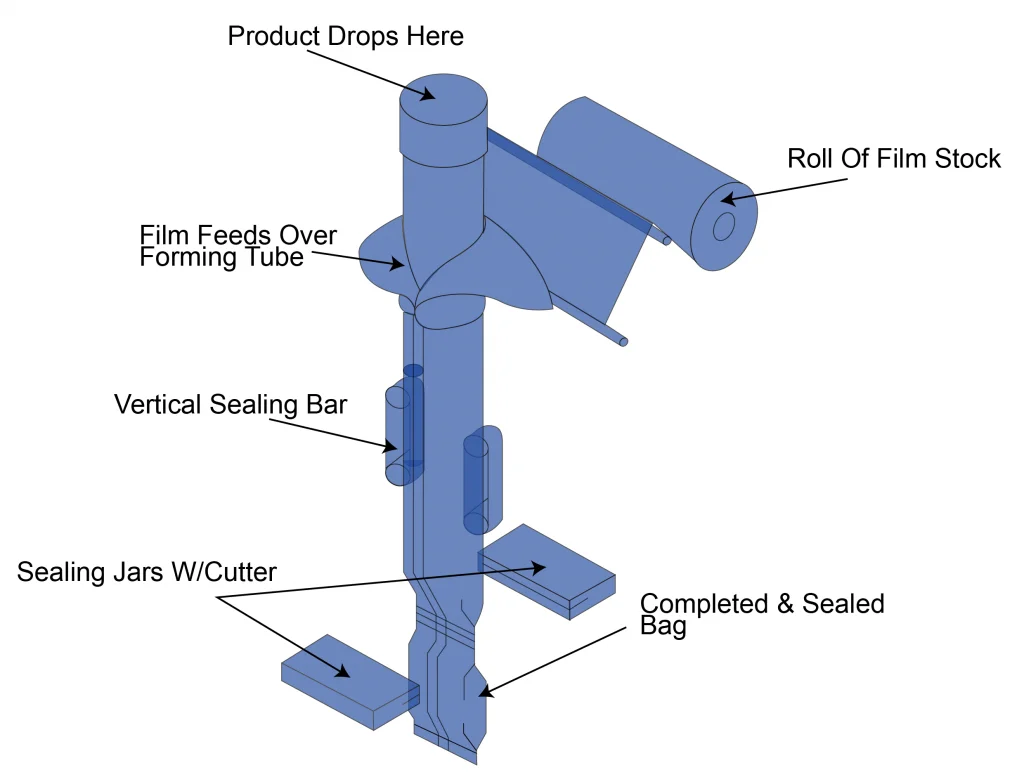

3. What bag types and sizes can the machine produce?

Supported bag types: pillow bag, gusset bag and quad-seal bag. Lengths: up to 340 mm (standard) or up to 460 mm (extended). Width ranges: 80–200 mm (ZD-540) and 100–240 mm (ZD-730). Depth (gusset/quad dimensions) and corner size vary by model: depth typically 50–120 mm and corner 5–10 mm depending on bag type and model.

4. What is the production speed (throughput)?

Intermittent operation with an adjustable speed of approximately 10 to 60 bags per minute. Actual throughput depends on bag size, weight per bag, product characteristics and selected weighing parameters.

5. What weighing system is used and how accurate is it?

The machine is equipped with a waterproof 14-head multihead weigher integrated with the vertical packer. Accuracy depends on the product, target weight and calibration; expected accuracy should be confirmed via product trials with the supplier.

6. What film/reel specifications does it accept?

Reel film width: 540 mm (ZD-540) or 730 mm (ZD-730). Reel outer diameter: up to 400 mm (ZD-540) or 500 mm (ZD-730). Reel inner/core diameter: 75 mm. Film must be heat-sealable (laminates/PE/CPP, etc.) — confirm specific film type and thickness compatibility with the supplier.

7. What are the electrical and pneumatic requirements?

Standard electrical: 220 V / 50 Hz single phase (other specifications available per customer request). Power consumption: about 3 kW (ZD-540) or 4 kW (ZD-730). Air pressure requirement: 0.6 MPa with air consumption about 0.6 m3/min.

8. What safety and hygiene features are included?

Safety: machine alarms and stops if there is no film, inadequate air pressure, or if safety guards are opened (guards have safety switches). Hygiene: product-contact parts are built for hygienic construction; the system supports easy cleaning and sanitary operation.

9. What level of automation and controls does the machine have?

High automation: PLC control with color touch-screen HMI, automatic film position control, servo-driven film pull and horizontal sealing, automatic printing/punching/countering and unmanned operation during weighing and packing. Faults and alarms are displayed on the touch screen.

10. How long does it take to changeover between bag types or sizes?

The machine is designed for quick changeovers; typical adjustments take about 10 minutes to change different pouch formats, depending on which parts need to be changed and operator experience.

11. What auxiliary equipment is included or recommended?

Standard supply includes the multihead weigher, vertical filling packaging machine, platform and Z-type elevator. Finished-product conveyor and vibrating hopper are available/commonly used. The machine can also be integrated with upstream feeding equipment or downstream checkweighers and metal detectors.

12. What footprint and machine weight should I plan for?

ZD-540 footprint: approximately 1300 x 1650 x 1650 mm and weight about 1000 kg. ZD-730 footprint: approximately 1450 x 2600 x 1950 mm and weight about 1200 kg. Allow extra space for operator access, maintenance and material handling.

13. What maintenance and cleaning are required?

Routine cleaning of product-contact parts after production runs and regular inspection/lubrication of moving parts is recommended. Check and replace sealing jaws, belts and air filters as needed. Follow the supplier's maintenance schedule and safety lockout procedures.

14. How do I get product-specific performance data, spare parts or service?

For expected accuracy, sample testing, spare parts lists, warranty, on-site installation, training and service agreements, contact the manufacturer or authorized distributor with product samples and required bag specifications so they can provide tailored data, quotes and service options.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading