B21, China Town Mall, Midrand

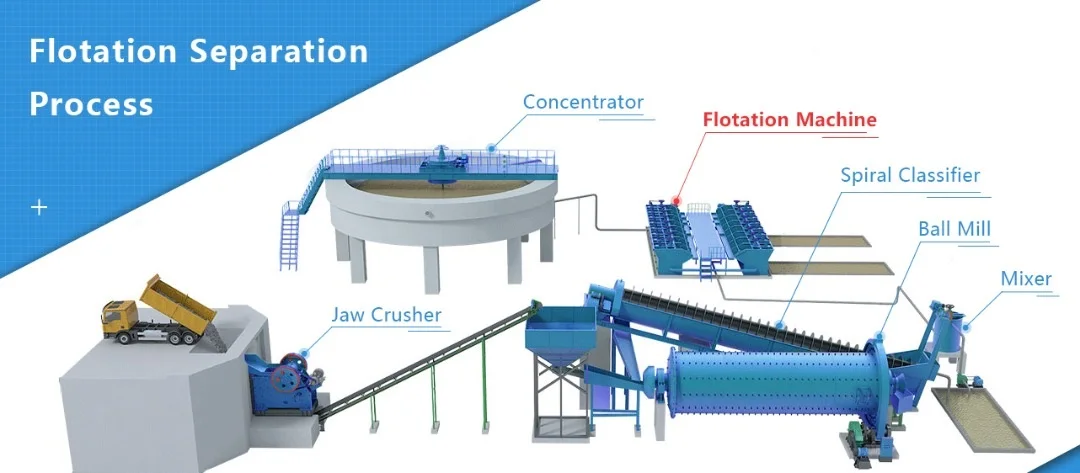

Mining Machinery Gold Ore Flotation Separator

- Section : Machinery

- Category : Mining Machinery

- SKU : 1600975794047

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 04 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the primary function of the Mining Machinery Gold Ore Flotation Separator?

The primary function is to separate valuable minerals from non-valuable minerals using the flotation process, which involves attaching hydrophobic particles to air bubbles to float them to the surface.

2. What types of ores can this flotation machine process?

This flotation machine can process a variety of ores including ferrous metal ores, precious metal ores, non-ferrous metal ores, sulfide minerals, oxide minerals, and non-metallic minerals.

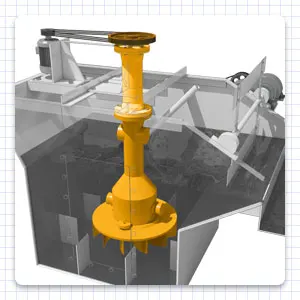

3. How does the flotation process work?

In the flotation process, the slurry mixed with chemicals is stirred, and air is inhaled, causing valuable minerals to adhere to bubbles and rise to the surface, while waste materials remain in the slurry.

4. What is the recovery rate for different types of ores?

Recovery rates vary by ore type; for instance, copper recovery can reach up to 95.24% for certain ores, while tungsten ore can have recovery rates greater than 65%.

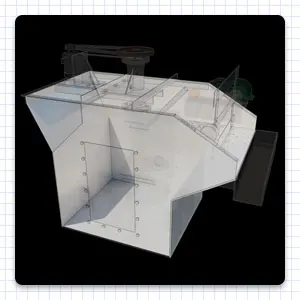

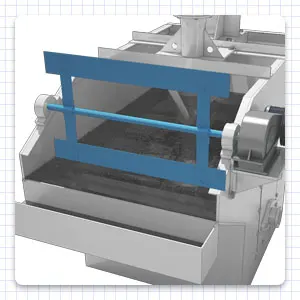

5. What are the key components of the flotation machine?

Key components include the flotation cell, mixing device, aeration device, and mineralized foam discharging device, each playing a crucial role in the flotation process.

6. Is this flotation machine suitable for small-scale operations?

Yes, the flotation machine is designed to be cost-effective and can be adapted for small-scale operations, making it suitable for various project sizes.

7. What is the power requirement for the flotation machine?

The motor power varies by model, with options ranging from 5.5 kW to 11 kW, depending on the specifications of the flotation machine.

8. What is the pulp concentration range for this flotation machine?

The pulp concentration range for the flotation machine is typically between 20% to 50%.

9. Can the flotation separator handle different particle sizes?

Yes, the flotation separator can handle feed particle sizes up to 40 mm.

10. What are the environmental impacts of using this flotation machine?

The flotation solutions are designed to minimize environmental impact while maximizing recovery and throughput, ensuring sustainability in mineral processing.

11. What is the expected lifespan of the flotation machine?

The lifespan of the flotation machine can vary based on usage and maintenance, but with proper care, it can last several years.

12. How do I adjust the slurry surface in the flotation cell?

The flotation cell is equipped with a gate device that allows for easy adjustment of the slurry surface to optimize the separation process.

13. What is the gross weight of the flotation machine?

The gross weight of the flotation machine varies by model, with weights ranging from approximately 5.2 tons to 8.9 tons.

14. Is installation support provided for the flotation machine?

Yes, installation support is typically provided by the manufacturer to ensure proper setup and operation of the flotation machine.

15. Where can I find replacement parts for the flotation machine?

Replacement parts can usually be obtained from the manufacturer or authorized distributors, ensuring compatibility and quality.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading