B21, China Town Mall, Midrand

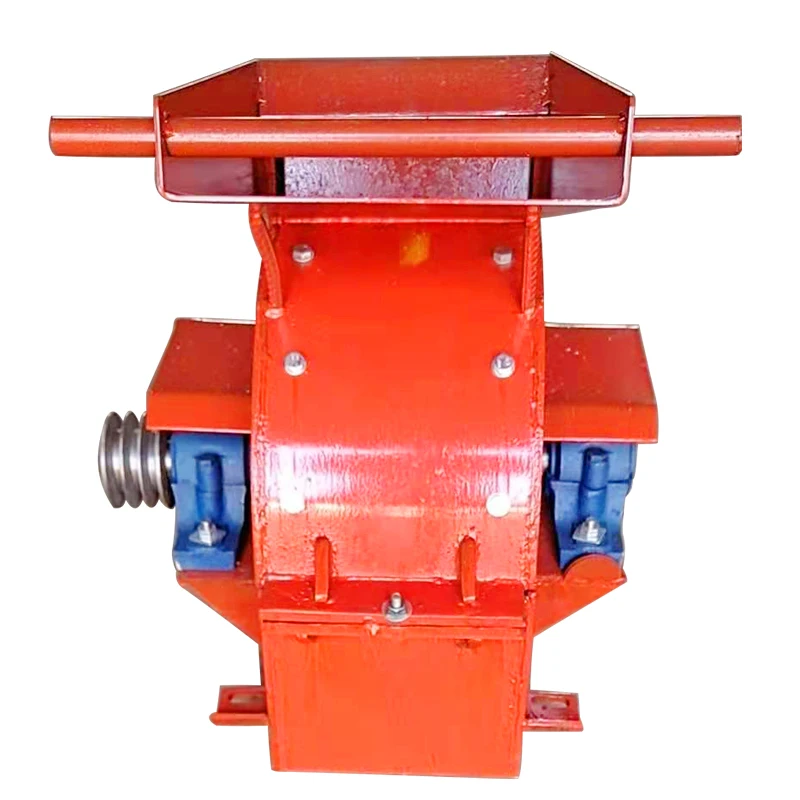

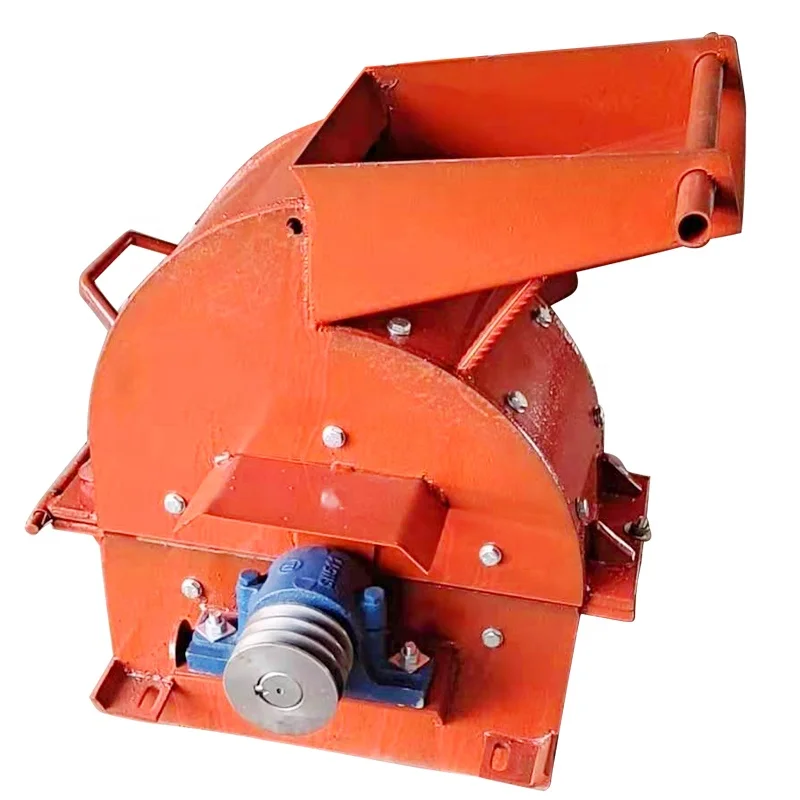

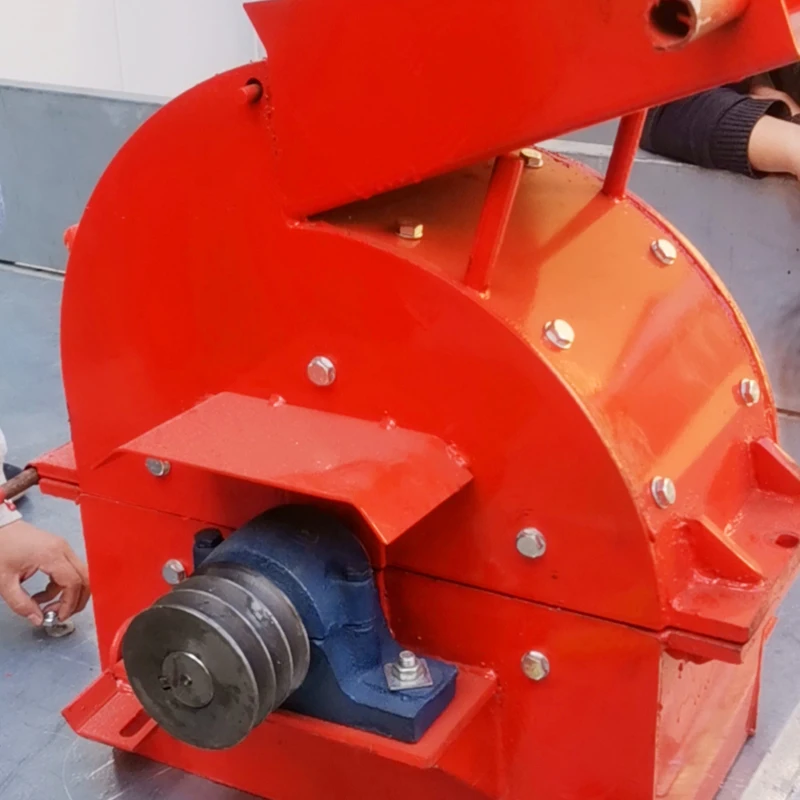

Mini Electric Hammer Crusher Model: 6B

- Section : Machinery

- Category : Mining Machinery

- SKU : 1600467752131

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 03 Feb, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the Mini Electric Hammer Crusher Model 6B?

The Mini Electric Hammer Crusher Model 6B is a compact hammer crusher designed for breaking small to medium-sized materials (e.g., brick, limestone, coal, slag) using an electric motor. It's a small-scale industrial crusher intended for workshops, small quarries and recycling applications.

2. Which models are available in this product line?

The product line includes models 6B, 8B and 10B. The listing specifically identifies the 6B as the mini electric hammer crusher model referenced.

3. What are the key specifications for Model 6B?

According to the provided description, typical specifications include a hole (feed) size of around 250×500 mm, a rotor speed of 3150 r.p.m., a net weight of approximately 126 kg, a gross weight of approximately 146 kg, and overall dimensions of about 500×600×600 mm.

4. What does the 'hole diameter' or feed size mean?

The hole diameter (feed size) refers to the maximum size of material that can be fed into the crusher inlet. For Model 6B the feed opening is listed around 250×500 mm—material larger than that should be reduced before feeding.

5. What power source does the 6B use?

The product is described as a Mini Electric Hammer Crusher, so it is driven by an electric motor. Exact motor power and electrical specifications are not provided in the description and should be confirmed with the supplier for your application.

6. The description mentions 'parts of diesel engine' under shipping details—does this product use a diesel engine?

Despite that line, the product name specifies 'Electric'. The shipping note likely means diesel-engine parts/accessories can be supplied as separate items or that the supplier also ships diesel-engine parts. Confirm with the supplier if you require a diesel-powered drive or any engine-mounted kit.

7. What materials can this hammer crusher process?

Hammer crushers are commonly used for limestone, coal, gypsum, shards, tile, brick, and other medium-hard non-abrasive materials. Performance depends on feed size, hardness and moisture; check with the supplier for suitability for your specific material.

8. What is the expected capacity (throughput) of Model 6B?

The provided description does not list throughput. Capacity depends on material type, feed size and motor power. Ask the supplier for a capacity chart or estimated throughput for your material and operating conditions.

9. What accessories and spare parts are included or available?

The shipping/details note mentions 'high-quality accessories' and spare parts; typical accessories include hammers/rotor parts, liners, screens and fasteners. Confirm the exact packing list and spare parts availability with the supplier before purchase.

10. What are the machine weights and packing dimensions?

The description lists a net weight of about 126 kg and a gross weight of about 146 kg, with product dimensions roughly 500×600×600 mm. Actual packed dimensions and weight may vary; request the supplier's packing list for shipping arrangements.

11. How should the Mini Electric Hammer Crusher be installed?

Install on a flat, level foundation with proper anchoring. Ensure correct alignment of the motor and adequate electrical supply. Provide safe feed and discharge chutes, and allow space for maintenance access. Follow the supplier's installation manual for torque, grounding and safety procedures.

12. What routine maintenance is required?

Regular checks should include inspection of hammers/rotor, wear liners, fasteners and screens; lubrication of bearings per schedule; checking motor mounts and electrical connections; and clearing any blockages. Replace worn parts promptly to avoid secondary damage.

13. What safety and environmental controls are recommended?

Install guarding over moving parts, emergency stop devices, and feed controls to avoid overloading. Use dust suppression (e.g., water sprays, extraction) and personal protective equipment (PPE) for operators. Follow applicable local safety standards and the supplier's safety guidelines.

14. Is there warranty and after-sales support?

The description does not specify warranty terms. Most suppliers offer limited warranty and spare-parts support—confirm warranty length, scope, and available after-sales service (parts, technical support, installation) with the seller prior to purchase.

15. How is the machine shipped and packaged?

The listing indicates shipment with high-quality accessories and durable packaging; gross weight is listed to help with logistics. For exact packaging method, dimensions, lead time, and whether additional items (e.g., diesel engine parts) are included, verify shipping details with the supplier.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals