B21, China Town Mall, Midrand

Low Air Pressure Mining Machinery DTH Hammer KQ17

- Section : Machinery

- Category : Mining Machinery

- SKU : 1600995867228

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 05 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

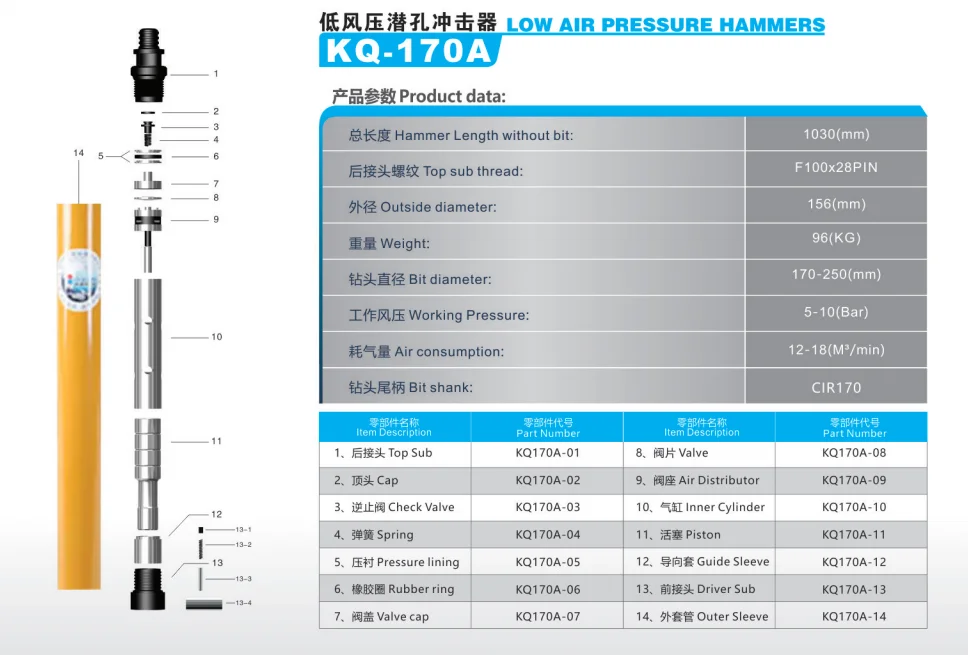

1. What is the Low Air Pressure Mining Machinery DTH Hammer KQ17?

The KQ17 is a down-the-hole (DTH) percussion hammer designed for mining and quarry drilling where compressed-air availability or pressure is limited. It transfers impact energy directly to the drill bit to break rock efficiently at lower air pressures than standard DTH hammers.

2. What air pressure range does the KQ17 operate at?

The KQ17 is optimized for low air pressure systems. Typical operation is with compressor outputs in the low-bar range (consult the product datasheet or manufacturer for the exact recommended operating pressure for this model).

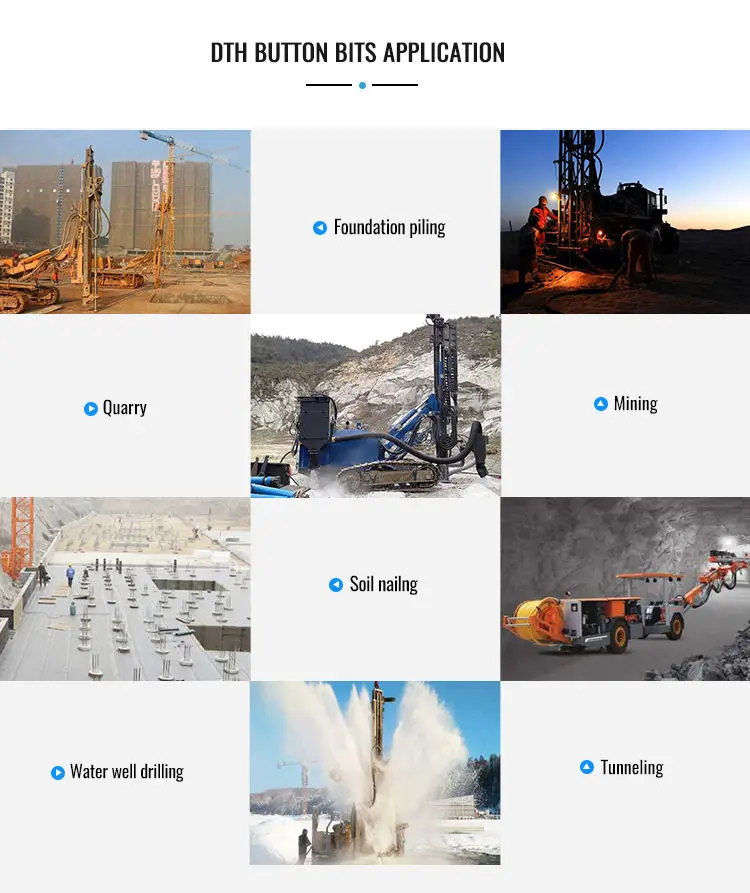

3. What drilling diameters and applications is the KQ17 suitable for?

The KQ17 is usually used for medium-diameter blast-hole and exploration drilling in mining, quarrying, and water-well applications where low air pressure is required. Consult the technical specifications to confirm compatible bit sizes and hole diameters.

4. What bit connection/shank types does KQ17 accept?

KQ-series hammers commonly accept industry-standard DTH bit shanks (threaded or shank type as specified). Verify the exact shank/thread type for the KQ17 in the product specification to ensure compatibility with your drill bits.

5. What are the main components and replaceable parts of the KQ17?

Typical replaceable components include the piston, inner/outer valves, seals, O-rings, retaining rings, and wear-resistant drill bits. Spare parts kits from the manufacturer are recommended for proper fit and performance.

6. How often should I perform maintenance on the KQ17?

Routine maintenance frequency depends on drilling conditions and usage. Inspect seals, piston, and valve components regularly (daily visual checks and more thorough inspections every 50–200 hours of operation is common). Follow the manufacturer's maintenance schedule for exact intervals.

7. What lubrication or air treatment does the hammer require?

Use clean, dry, oil-lubricated or oil-injected compressed air per the manufacturer's guidance. Proper filtration and moisture separation are important to prevent premature wear; some operators use inline lubricators and filters to maintain air quality.

8. What are common causes if the hammer loses impact or power?

Loss of impact can be caused by insufficient air pressure or volume, worn piston or valves, damaged seals, incorrect bit fit, or air leaks. Check the compressor output, air lines, seals, and internal wear parts and replace any worn components.

9. Is the KQ17 compatible with low-volume air compressors?

The KQ17 is designed for lower-pressure systems, but compatibility with low-volume compressors depends on the compressor's free air delivery (FAD) and pressure. Confirm required FAD and pressure in the technical data before pairing with your compressor.

10. What safety precautions should operators take when using the KQ17?

Always depressurize and secure the drill string before maintenance, wear appropriate PPE (hearing, eye, and hand protection), follow lockout/tagout procedures, and adhere to site safety protocols. Only trained personnel should service the hammer.

11. How do I install the KQ17 on my drill rig?

Installation typically involves securely coupling the hammer to the drill string or adapter, fitting the correct bit, checking thread/shank compatibility, and verifying air supply connections and seals. Follow the manufacturer's installation instructions for torque values and mounting procedures.

12. What is the expected service life of the KQ17?

Service life varies widely with rock type, operating conditions, maintenance, and air quality. With proper maintenance and correct operating parameters, wear parts like pistons and bits will need periodic replacement while the hammer body can last many thousands of operating hours.

13. Where can I get spare parts and technical support for the KQ17?

Contact the manufacturer or authorized dealer for genuine spare parts, technical documentation, and after-sales support. Using OEM parts and following their guidance ensures compatibility and optimal performance.

14. What warranty and after-sales services are typically offered?

Warranty and after-sales services vary by manufacturer and seller. Check your purchase agreement for warranty duration, coverage details, and available service plans. Many suppliers offer technical support, parts kits, and repair services.

15. How should I troubleshoot air leaks or poor hammer performance?

Start by checking all air connections, hoses, and fittings for leaks, ensure the compressor meets required pressure and FAD, inspect seals and O-rings inside the hammer, and examine the piston and valve assembly for wear. Replace damaged seals or worn components and consult the manufacturer if problems persist.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading