B21, China Town Mall, Midrand

LCUT Plasma CNC Cutting Machine

- Section : Machinery

- Category : Other Apparel Machines

- SKU : 1600791141632

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 11 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the LCUT Plasma CNC Cutting Machine?

The LCUT Plasma CNC Cutting Machine is a multi-function cutting system designed for precision cutting in industries such as garment shops, manufacturing, and printing. It supports plasma and oscillating-knife cutting modes for accurate, efficient processing of various materials.

2. What are the machine's cutting area and physical size considerations?

The cutting area is 1600 x 1600 mm. The overall machine footprint is larger than the cutting area; contact the supplier for full machine dimensions and recommended workspace requirements.

3. What cutting thickness can the LCUT handle?

Cutting thickness is up to ≤50 mm, though the exact maximum depends on material type and the chosen cutting configuration; thicker-capacity options can be customized.

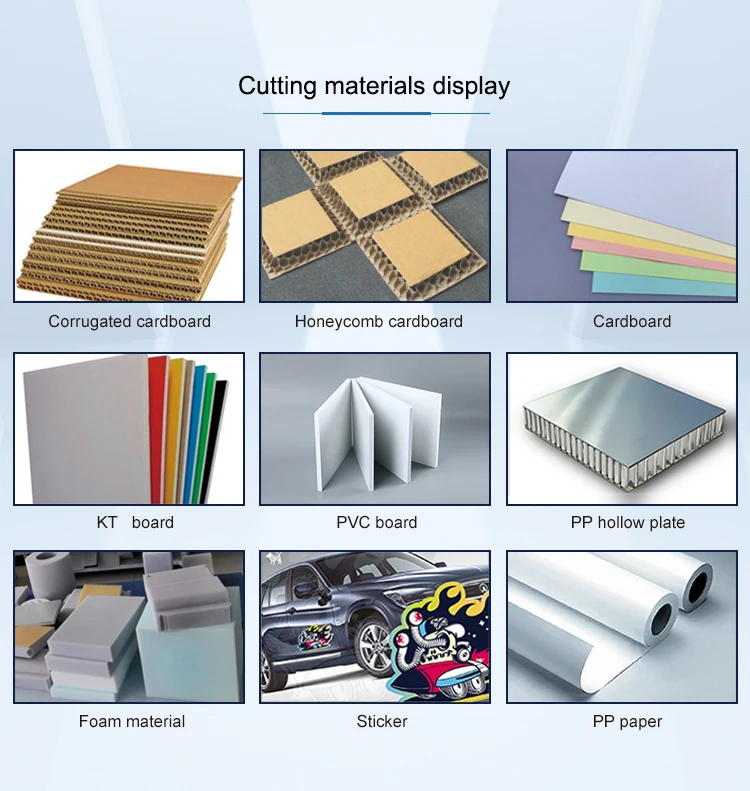

4. What materials can be cut with this machine?

Typical applicable materials include carton box, paper card, cardboard, KT board, stickers, rubber, EVA, foam and similar sheet materials. Material suitability depends on the selected cutting head (oscillating knife vs. plasma).

5. What cutting speeds and precision does the LCUT offer?

Cutting speeds range from 100 to 1400 mm/s. Repeat precision is 0.05 mm, ensuring consistent high-accuracy results for production jobs.

6. Which drive and power specifications does the machine use?

The LCUT uses imported servo motors for driving. Total power is 9 kW, and the vacuum/fan unit is specified as 220 V / 2.2 kW.

7. Which data formats and interfaces are supported?

The unit supports common CAD/CAM formats such as DXF, HPGL, PLT, etc. Interfaces include USB and Ethernet ports for file transfer and network integration.

8. What safety features are included?

The machine is equipped with infrared sensing devices and other built-in safety protections to help ensure a safe operating environment.

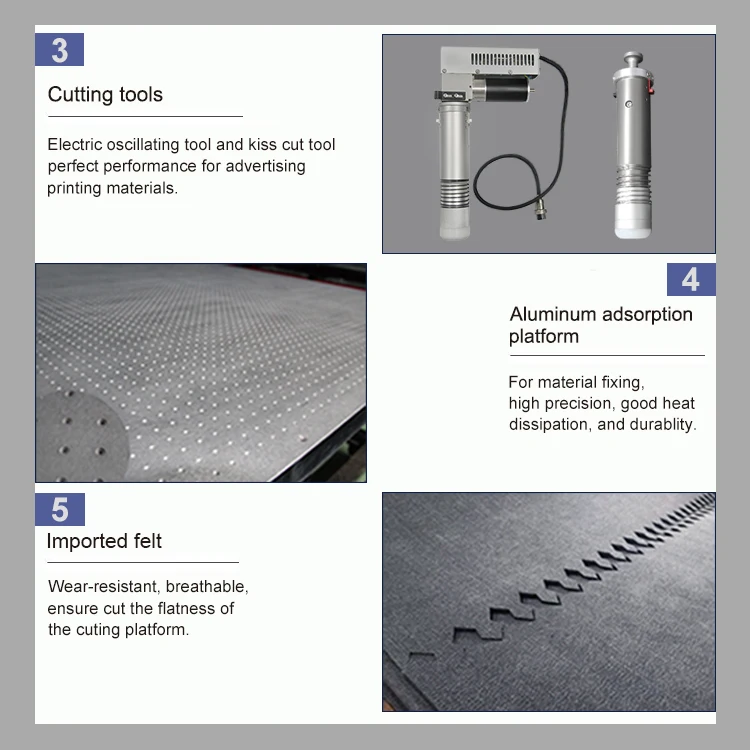

9. How does the material fixation system work?

The LCUT uses a vacuum partition adsorption system to hold materials flat and secure during cutting, improving accuracy and preventing shifting.

10. Does the LCUT support customization?

Yes. The machine supports customization to meet specific project or material requirements—contact the manufacturer or dealer to discuss options and lead times.

11. Is the machine suitable for both oscillating knife and plasma cutting?

Yes. The LCUT is offered as a Plasma CNC cutter and/or an Oscillating Knife Cutting Machine depending on configuration; choose the cutting head appropriate for your material and application.

12. How much does the LCUT weigh?

The listed machine weight is approximately 1000 kg. Shipping and installation requirements should account for this weight.

13. What routine maintenance is recommended?

Regular maintenance includes keeping rails and guides clean and lubricated, inspecting/replacing blades or consumables, checking vacuum system and filters, cleaning infrared sensors, and keeping firmware/software up to date. Follow the manufacturer's maintenance schedule for best results.

14. What support or training is available for operators?

Manufacturers or dealers typically provide installation assistance, operator training, and technical support. Ask your supplier about on-site training, user manuals, and after-sales service packages.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading