B21, China Town Mall, Midrand

Large capacity sand sieving linear probability vibrating screen gravel sifter machine

- SKU : 60779439109

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 02 Mar, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the purpose of the Large Capacity Sand Sieving Linear Probability Vibrating Screen?

This machine is designed to efficiently separate and grade various materials such as sand, gravel, and other aggregates based on particle size, enhancing productivity in construction and mining applications.

2. What are the available models for this vibrating screen?

The vibrating screen is available in four models: GLS-1020, GLS-1225, GLS-1536, and GLS-1836, each differing in size, capacity, and power.

3. What is the maximum feed particle size for each model?

The maximum feed particle size for the models is as follows: GLS-1020 can handle >10 mm, GLS-1225 can handle >20 mm, GLS-1536 can handle >30 mm, and GLS-1836 can handle >40 mm.

4. How much power does each model consume?

Power consumption varies by model: GLS-1020 uses 1.5 KW, GLS-1225 uses 2.2 KW, GLS-1536 uses 3.7 KW, and GLS-1836 also uses 3.7 KW.

5. What is the capacity of each model in terms of throughput?

The capacities are as follows: GLS-1020 has a capacity of 30 T/H, GLS-1225 has >20 T/H, GLS-1536 has >30 T/H, and GLS-1836 has >40 T/H.

6. What is the screen mesh size for these models?

The screen mesh sizes for the models are as follows: GLS-1020 has a mesh size of 0.6 mm, GLS-1225 has a mesh size of 2 mm, GLS-1536 has a mesh size of 2 mm, and GLS-1836 also has a mesh size of 2 mm.

7. Is the vibrating screen suitable for wet materials?

Yes, the vibrating screen can be used for wet materials; however, adjustments may be needed to optimize performance depending on the specific application.

8. How does the linear probability vibrating screen differ from other types of screens?

Linear probability vibrating screens are designed to provide a more uniform and efficient separation process compared to other types, such as circular screens, which may not handle materials as effectively for specific applications.

9. What maintenance is required for the vibrating screen?

Regular maintenance includes checking and tightening bolts, inspecting screen meshes for wear and tear, and ensuring the vibratory mechanism is functioning correctly to maintain optimal performance.

10. Can the screen size be customized?

Custom sizes and specifications may be available upon request; please contact our sales team for more information on customization options.

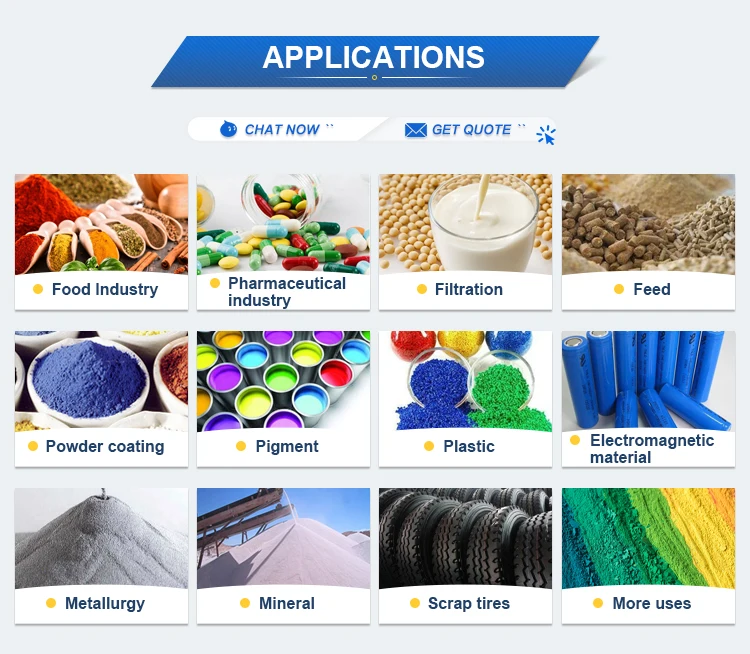

11. What industries commonly use this vibrating screen?

This machine is commonly used in construction, mining, aggregate production, and recycling industries where efficient material separation is required.

12. What is the warranty period for this product?

The warranty period typically varies by manufacturer; please refer to the purchase agreement or contact customer service for specific warranty details.

13. How is the machine installed?

Installation typically involves securing the machine to a stable foundation, connecting the power supply, and ensuring that the feed and discharge points are correctly aligned.

14. What safety features are included with the vibrating screen?

Safety features may include emergency stop buttons, protective covers, and vibration dampening systems to ensure safe operation.

15. What is the shipping method for this product?

Shipping methods can vary; typically, large machinery is shipped by freight. Specific shipping options will be discussed at the time of purchase.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals