B21, China Town Mall, Midrand

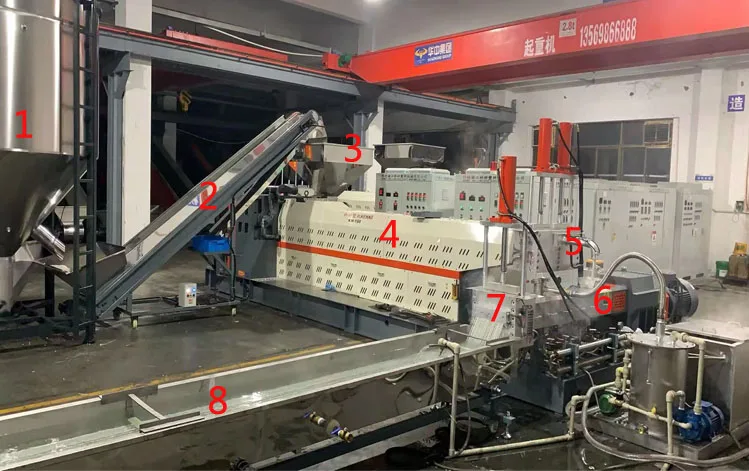

KEHAO Plastic Pelletizing Machine

- Section : Machinery

- Category : Plastic & Rubber Processing Machinery

- SKU : 62424492247

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 04 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What types of plastics can the KEHAO Plastic Pelletizing Machine process?

The KEHAO Plastic Pelletizing Machine can process various types of plastics, including HDPE, LDPE, PET, ABS, and more.

2. What is the motor specification for the KEHAO Plastic Pelletizing Machine?

The machine is equipped with a Siemens motor, known for its reliability and efficiency.

3. How does the pelletizing method work?

The KEHAO machine utilizes a strand cutting pelletizing method, producing uniform particles with lengths ranging from 2mm to 3mm.

4. What is the service life of the KEHAO Plastic Pelletizing Machine?

The machine is built with high-quality components designed for longevity, ensuring a long service life and a good return on investment.

5. Can the dimensions and power specifications be customized?

Yes, the dimensions and power specifications of the KEHAO Plastic Pelletizing Machine can vary based on the model, allowing for customization to meet specific requirements.

6. What is the output capacity of the KEHAO Plastic Pelletizing Machine?

Output capacity ranges from 200 to 520 KG/h, depending on the model.

7. Does the machine come with a cooling system?

Yes, the KEHAO Plastic Pelletizing Machine features different length tanks for cooling plastic noodles, and water can be recycled by a water tower.

8. Is the machine noisy during operation?

The pellets cutting machine operates with low noise due to the Siemens motor, making it suitable for various working environments.

9. What safety features are included in the design?

The machine includes a self-designed frequency feeder that can separate magnetic impurities, ensuring safer operation and better protection for the screw.

10. How does the machine handle different types of plastics?

Different feeders are designed for various plastic characteristics, allowing for even feeding and protection of the screw.

11. Is there an option for continuous operation?

Yes, the double station feature allows for changing the net without stopping the machine, facilitating continuous operation.

12. What materials are used in the construction of the machine?

The raw material used in construction is 38CrMoAl, providing durability and strength.

13. Can the machine improve the quality of the processed plastics?

Yes, the second plasticization process enhances the quality and output of the plastics being processed.

14. What are the key components of the KEHAO Plastic Pelletizing Machine?

Key components include the PLC, engine, bearing, gearbox, motor, and gear.

15. Where can I get technical support for the KEHAO Plastic Pelletizing Machine?

Technical support is typically provided by the manufacturer or authorized dealers. It's recommended to contact them directly for assistance.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading