B21, China Town Mall, Midrand

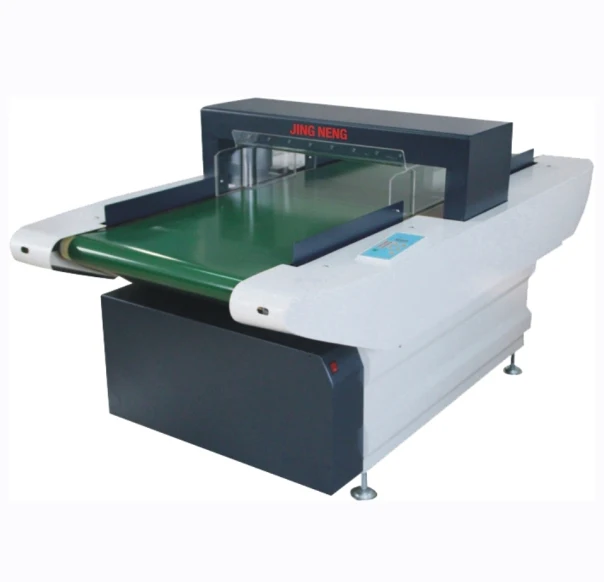

Jing Neng Broken Needle Detecting Machine

- Section : Machinery

- Category : Apparel Machinery

- SKU : 1600424812507

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 06 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the primary function of the Jing Neng Broken Needle Detecting Machine?

The primary function of the Jing Neng Broken Needle Detecting Machine is to efficiently detect broken needles in various manufacturing settings, ensuring safety and quality control by identifying metal contaminants.

2. What materials can the machine detect?

The machine is designed to detect ferrous materials, including broken needles, with a sensitivity to objects as small as 1.0mm.

3. What are the different detection heights the machine can accommodate?

The Jing Neng Broken Needle Detecting Machine can accommodate detection heights of 100mm, 150mm, and 200mm, making it versatile for different product sizes and configurations.

4. What is the detection width of this machine?

The machine features a broad detection width of 600mm, which enhances efficiency for larger batches.

5. How does the machine ensure accurate detection?

The machine utilizes magnetic induction technology, which ensures accurate and quick identification of broken needles.

6. What are the dimensions of the Jing Neng Broken Needle Detecting Machine?

The machine has a compact design with dimensions of 1650mm x 1030mm x 900mm, making it suitable for various workspaces.

7. What is the power requirement for the machine?

The Jing Neng Broken Needle Detecting Machine operates on 220V with a power consumption of 150W.

8. In which industries can this machine be used?

This machine is suitable for use in the textile, fabric, garment, and clothing industries, among others.

9. Is the machine energy-efficient?

Yes, the Jing Neng Broken Needle Detecting Machine maintains energy efficiency while providing powerful performance with a power consumption of only 150W.

10. How sensitive is the machine to detecting broken needles?

The machine offers impressive sensitivity, detecting ferrous materials as small as 1.0mm, ensuring thorough inspections.

11. Can the machine handle high production volumes?

Yes, with its broad detection width of 600mm, the machine is efficient for larger batches, enhancing productivity in manufacturing settings.

12. Does the machine require special training to operate?

While it is user-friendly, basic training on its operation and maintenance is recommended to ensure optimal performance and safety.

13. What maintenance does the machine require?

Regular cleaning and periodic checks of the detection system are recommended to maintain its efficiency and accuracy.

14. Is the machine portable?

The compact design of the machine allows it to fit in various workspaces, but it is best suited for stationary use in a production line.

15. What safety features are included in the machine?

The machine is designed to prioritize safety by effectively detecting metal contaminants, which helps prevent accidents in the manufacturing process.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading