B21, China Town Mall, Midrand

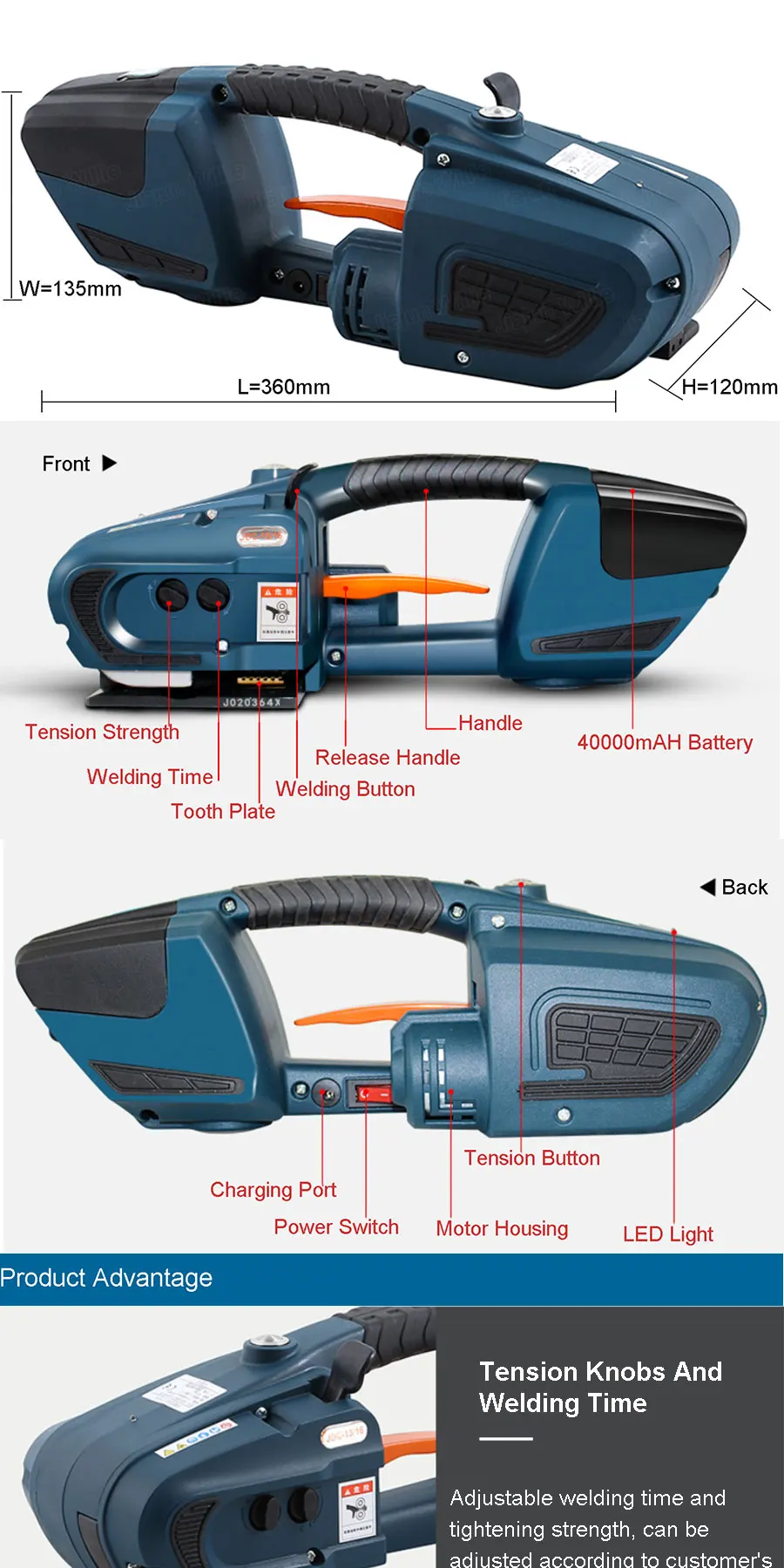

Jiajun Willie Battery Strapping Tool

- Section : Machinery

- Category : Packaging Machines

- SKU : 62246227346

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 05 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What strap types and sizes does the Jiajun Willie Battery Strapping Tool support?

The tool is compatible with PP and PET straps with widths of 13–16 mm and thicknesses from 0.4–1.2 mm.

2. What is the maximum tension force the tool can apply?

The tool can apply up to 2800 N (approximately 280 kgf) of tension, with an adjustable tension range starting around 60 N.

3. What are the physical dimensions and weight of the tool?

The compact dimensions are 360 × 135 × 120 mm, and the tool weighs approximately 3.2 kg.

4. What kind of battery does it use and how long does it take to charge?

It uses a NiMH 11.1 V, 4000 mAh battery. The included charger (100–245 V AC, 50–60 Hz) charges the battery in approximately 90 minutes.

5. How many straps can I tension/weld per charge?

Battery runtime depends on tension settings and usage frequency; with a 4000 mAh battery you can expect multiple cycles per charge. For exact cycle estimates under your typical workload, contact our after-sales support.

6. Is the tool easy to operate for novice users?

Yes. The Jiajun Willie is semi-automatic and designed for simple operation: place the strap, insert the tool, activate tension, then weld/cut. A brief orientation or the supplied user guide is recommended.

7. What welding method does the tool use to seal straps?

The tool uses friction welding (welding mold: friction welding) for secure strap seals.

8. What warranty and quality assurances are provided?

The tool comes with a 1-year warranty. Each unit includes machinery test reports and video outgoing inspections to verify quality prior to shipment.

9. What after-sales and technical support are available?

Comprehensive after-sales support is provided, including online help and video technical assistance for troubleshooting, setup, and spare part requests.

10. What basic maintenance is recommended to keep the tool working reliably?

Keep the tool clean and dry, remove strap debris from the feed path, inspect the friction welding mold and cutting parts for wear, charge the battery per instructions, and replace worn parts as needed. Contact support for replacement parts.

11. What should I do if the tool does not reach full tension or does not weld?

First check battery charge and strap type/condition (use correct width/thickness and undamaged strap). Ensure straps are properly positioned and feeding smoothly. If issues persist, consult the troubleshooting video or contact after-sales support.

12. Are spare parts and accessories available?

Yes. Spare parts and accessories (replacement welding molds, cutters, batteries, etc.) can be obtained through our after-sales channels—contact support for part numbers and ordering.

13. Are there any safety precautions I should follow when using the tool?

Wear appropriate PPE (gloves, safety glasses), keep hands clear of the welding and cutting areas, do not exceed strap specifications or the maximum tension, avoid using the tool in wet conditions, and follow the user manual and charging safety guidelines.

14. Can this tool be used in food and beverage packaging environments?

Yes. The tool is designed for efficiency in food, beverage, and commodity packaging applications. Ensure you follow your facility's hygiene and cleaning protocols when using the tool in food-handling areas.

15. Where can I find the user manual, test reports, and inspection videos?

User manuals, machinery test reports, and outgoing inspection videos are provided with the product. If you need digital copies, contact our after-sales support and they will supply the documents and links.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading