B21, China Town Mall, Midrand

Industrial Sand Sifting Silica Sand Vibrating Screen

- Section : Machinery

- Category : Industrial Machinery

- SKU : 1600645557422

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 24 Mar, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

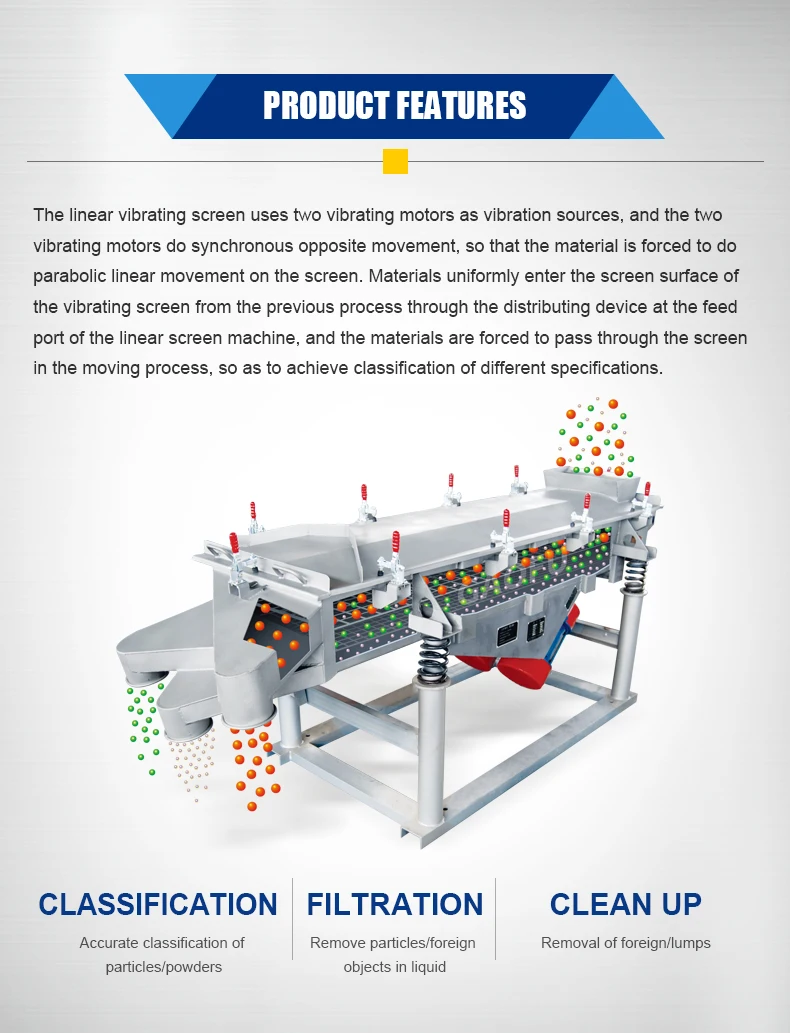

1. What is an Industrial Sand Sifting Silica Sand Vibrating Screen and how does it work?

It is a linear vibrating sieve designed to separate silica and industrial sands by particle size. The machine uses an electric motor with an eccentric vibrator or exciter to generate vibration; material moves across a tensioned screen mesh while particles smaller than the mesh pass through and larger particles travel to the discharge end.

2. What are the typical applications for this vibrating screen?

Common uses include grading and de-sliming silica sand, quartz sand, foundry sand, construction sand, and other granular minerals in mining, aggregate, glass, and building materials industries.

3. What screen mesh sizes are available?

Screen mesh options vary by model and can range from very fine meshes for dust and fine sand to coarse openings for lump removal. Typical options cover fine powders up to several millimeters; consult the supplier for specific mesh sizes and custom screen cloth options (stainless steel woven, polyurethane, perforated plate).

4. How do I choose the right model and capacity for my operation?

Capacity depends on feed particle size distribution, material bulk density, moisture content, required cut points, and mesh size. Provide a sample, target gradation, and desired throughput to the manufacturer or supplier for a recommended model and estimated throughput.

5. Can the machine handle wet or sticky sand?

Vibrating screens work best with dry to moderately damp sand. High moisture or sticky materials can cause blinding and reduced efficiency; for wet feeds consider wet screening, dewatering equipment, or anti-blinding screen media and cleaning devices (e.g., ultrasonic, ball trays).

6. What materials are used in construction and are sanitary options available?

Standard construction uses carbon steel with wear-resistant coatings. Contact suppliers offer stainless steel frames and food- or pharma-grade finishes and seals when required for sanitary or corrosive environments.

7. What are the main maintenance tasks and service intervals?

Routine tasks include checking and retensioning screen media, lubricating bearings, inspecting springs and mounts, tightening bolts, and cleaning debris. Frequency depends on operating hours and material abrasiveness; daily visual checks and scheduled weekly/monthly preventive maintenance are typical.

8. What spare parts should I keep on hand?

Common spare parts include screen cloths, springs, bearings, motor couplings, eccentric weights or exciters, bolts, and gaskets. Keeping at least one spare screen panel and bearings is recommended to minimize downtime.

9. How is the machine installed and what foundation is required?

The screen is typically mounted on vibration isolation springs and anchored to a level, rigid foundation. Requirements depend on model size and vibration force; follow manufacturer installation drawings and secure electrical and feed/discharge conveyors to maintain alignment.

10. What are the power and control requirements?

Power depends on machine size and capacity; smaller units may use motors under 1 kW while large industrial models use multiple kilowatts. Controls often include VFDs for adjustable vibration frequency and amplitude, motor starters, and safeguarding. Confirm electrical specs with the supplier.

11. How efficient is the screening and what factors affect screening accuracy?

Screening efficiency depends on proper mesh selection, feed distribution, vibration amplitude/frequency, bed depth, feed rate, and moisture. When these are optimized, vibrating screens can achieve high separation efficiency for targeted particle sizes.

12. Are there dust control or environmental options?

Yes. Dust covers, full enclosures, negative-pressure extraction ports, and baghouse or scrubber attachments are available. Choose sealing, enclosure, and dust-collection solutions based on site regulations and dust levels.

13. What safety features should be used with this equipment?

Install guards over moving parts, emergency stop controls, vibration isolators, and lockout-tagout procedures for maintenance. Train personnel on safe operation and ensure electrical protections are in place.

14. What warranty and after-sales support are typically offered?

Warranty periods vary by manufacturer but commonly cover 12 months for workmanship and major components. Ask about after-sales support including spare-part availability, field service, commissioning, and maintenance contracts when ordering.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals