B21, China Town Mall, Midrand

Hydraulic Press Y32

- Section : Machinery

- Category : Machine Tool Equipment

- SKU : 62210872909-1713450201

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 05 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What are the key specifications of the Hydraulic Press Y32?

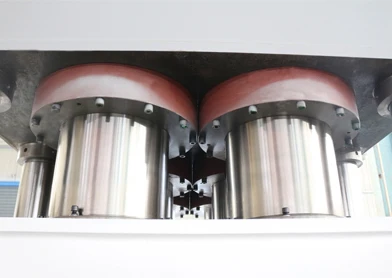

The Y32 features a dual motor system totalling 45 kW, a machine weight of 45 tons, a slide stroke of 500 mm, and a return force of 200 kN. It uses high-quality bearings and components and offers customizable dimensions to fit production needs.

2. What model sizes and nominal forces are available?

Model options listed include 200T, 315T, 400T, 500T, 630T, 800T, 1000T and 1250T. Corresponding nominal force values are shown in the product spec as 2000 kN up to 12,500 kN, matching the respective model sizes.

3. Which industries and applications is the Y32 suitable for?

The Y32 is suited for heavy-duty industrial applications such as metal forming, stamping, blanking, molding, assembly, compressing and other pressing operations where high productivity and durability are required.

4. What control and electrical components does the machine use?

The press includes a touch-screen control panel, PLC control, and Siemens electrical parts. Exact electrical connection (voltage/phase) should be confirmed with the supplier based on site requirements.

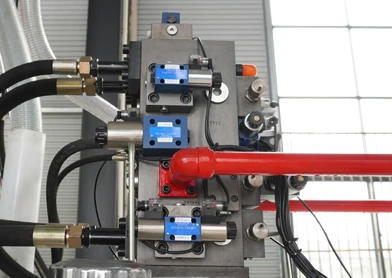

5. What hydraulic components and seals are used?

The Y32 is equipped with precision hydraulic valves, cylinders, a return cylinder, steel oil tubing designed to reduce leakage, and NOK-brand seal rings from Japan.

6. Can the Y32 be customized to fit specific production layouts?

Yes. The Y32 offers customizable dimensions and configurations to suit different production layouts and tooling requirements. Discuss specific customization needs with the manufacturer or sales representative.

7. What tooling and die arrangements does the press support?

The machine supports a mold frame and skin mold, a double-action worktable for complex dies, and various die sizes within the limits of the 500 mm slide stroke and the press’s ram dimensions. Verify die envelope and clamping arrangements when ordering.

8. What are the installation and foundation requirements?

Due to the machine’s mass (45 tons) and heavy-duty operation, a reinforced concrete foundation and proper anchoring are recommended. Electrical supply must accommodate a 45 kW dual-motor system. Exact foundation drawings and site requirements will be provided by the manufacturer.

9. What routine maintenance is recommended?

Regular checks should include hydraulic oil level and condition, filters, seal rings, bearing lubrication, valve operation, electrical connections, and fastener torque. Follow the manufacturer’s maintenance schedule for oil change intervals and component inspections to minimize downtime.

10. What safety features and accessories are available?

Standard features include a foot switch and a movable/compact controller. The machine also has embossed door sheets for enclosure. Additional safety interlocks, guarding, light curtains or emergency stops should be specified depending on local regulations and application.

11. What are the expected lead times and availability of spare parts?

Lead times vary by configuration and customization. Critical components such as Siemens electrical parts, NOK seals and standard hydraulic parts are commonly stocked, but availability and delivery times should be confirmed with the supplier at order placement.

12. How do I determine if the Y32 has enough pressing force for my application?

Calculate the required tonnage based on material properties, part geometry and tooling (including clearance and blanking/shearing factors). If unsure, provide part drawings and material specs to the manufacturer or application engineer to select the correct model and press force.

13. What are the transport and lifting requirements for the Y32?

Because the machine weighs approximately 45 tons, heavy-duty transport and lifting equipment (cranes/rigging rated for the load) are required. The supplier will provide lifting points, weight distribution and transport dimensions to plan logistics.

14. Does the Y32 offer features to reduce oil leakage and improve longevity?

Yes. The press uses high-quality steel oil tubing designed to reduce the possibility of oil leakage, NOK seal rings, hardened materials for critical components, and quality bearings and motors to enhance longevity and reduce downtime.

15. How do cycle time and production rate depend on machine settings?

Cycle time depends on stroke length (up to 500 mm), load, hydraulic settings, tooling, and part handling. The dual-motor 45 kW system provides robust power, but actual production rate should be determined by testing with your specific tooling and material. Consult the manufacturer for optimization guidance.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading