B21, China Town Mall, Midrand

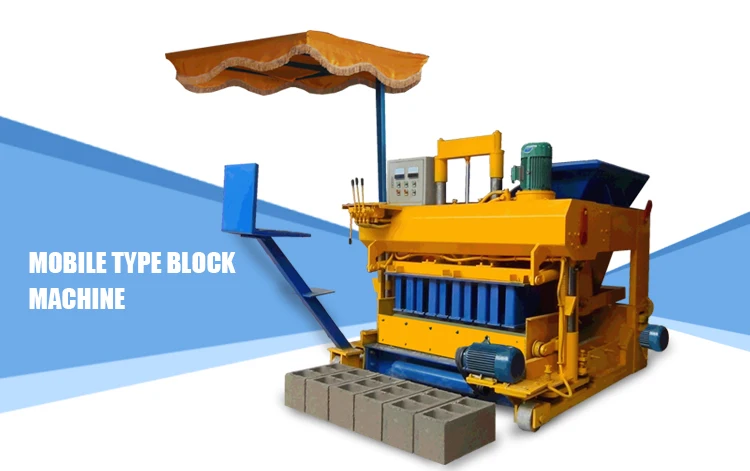

hydraulic construction building cement concrete block making machinery

- Section : Machinery

- Category : Brick Making Machinery

- SKU : 1600819584945

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 05 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the model and main specification of this machine?

The model is QMY6-30. Host machine dimensions are 2250×1950×1850 mm, weight 3 t, rated voltage 200 V/380 V (adjustable), main power 11.2 kW, vibration force 45 kN, mixer model JS500, and forming period 25–30 seconds per cycle.

2. What shaping/forming method does the machine use?

It uses mold vibration shaping: the block is formed in a steel mold while hydraulic pressure and vibration compact the concrete to the required density and shape.

3. What is the production capacity of the machine?

Cycle time is 25–30 seconds (120–144 cycles per hour). Actual block output depends on the mold cavity count and block size: blocks per hour = cycles per hour × mold cavities.

4. What raw materials can be used to make blocks with this machine?

Typical raw materials include cement, sand, crushed stone/aggregate, fly ash, slag, and water. Mix design depends on the block type (solid, hollow, paving) and should follow your engineering specification.

5. Is a mixer included and what capacity is it?

Yes, the JS500 mixer is specified as the supporting mixer. Confirm with the supplier for included accessories and whether the mixer is standard with your purchase.

6. What power supply is required and is voltage configurable?

The machine supports rated voltages of 200 V or 380 V (adjustable). Main motor power is 11.2 kW. Confirm required phase and local power details with the supplier/installer.

7. What are the site and installation requirements?

Provide a level, solid foundation or reinforced concrete pad larger than the machine footprint (2250×1950 mm), appropriate lifting equipment for placement (crane/forklift for 3 t), stable power supply, and access for raw materials and finished block removal. Anchor bolts and minor foundation works may be required.

8. How do I change molds for different block sizes?

Molds are replaceable. Stop the machine, isolate power, remove fastening bolts/fixtures, lift out the existing mold, position and secure the new mold, then check alignment and clearances before restarting. Follow supplier instructions and use proper lifting equipment.

9. What routine maintenance is required?

Daily: clean mixer and mold, check hydraulic oil level, lubrication points, and fasteners. Periodically: change hydraulic oil/filters per manufacturer schedule, inspect vibration system and seals, replace worn mold liners, and service the mixer. Keep a maintenance log.

10. What safety features and precautions should I follow?

Ensure emergency stop and power isolation are functional, keep guards in place over moving parts, train operators on safe procedures, lock out/tag out during maintenance, and wear PPE (gloves, boots, eye protection). Follow local safety regulations.

11. What spare parts should I keep on hand?

Common spares: mold liners, hydraulic seals and hoses, vibration motor parts, bearings, fasteners, electrical components (fuses/contactors), and mixer wear parts. Stocking critical spares minimizes downtime.

12. Can the machine be customized or are different models available?

Yes. Many suppliers offer different mold configurations, additional cavities, and voltage/motor options. Provide desired block size, output requirements, and local power when requesting customization.

13. How is the machine packaged and shipped?

Packaging and shipping vary by supplier. The host machine weighs about 3 t and is shipped on a pallet or skid; expect crating for protection. Confirm packaging details, freight terms, and required lifting arrangements with the seller.

14. What warranty and after-sales support is provided?

Warranty period and after-sales support depend on the manufacturer/supplier. Typical offerings include 12-month limited warranties and availability of technical support and spare parts; confirm exact terms before purchase.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading