B21, China Town Mall, Midrand

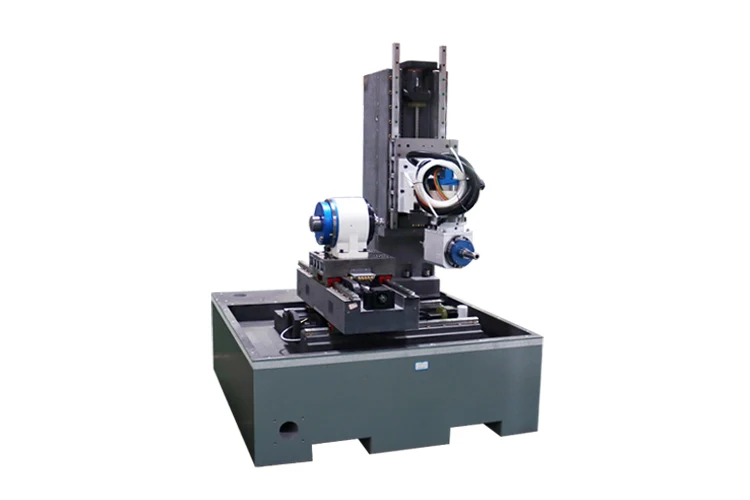

Horizontal CNC Cutter Grinders Lathe Milling Tool Grinding Machine

- Section : Machinery

- Category : Lathe

- SKU : 1601164986066

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 21 Mar, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What industries can benefit from the Horizontal CNC Cutter Grinders?

The Horizontal CNC Cutter Grinders are suitable for the IT, automotive, aerospace, and medical industries, among others, particularly in the metal grinding tools sector.

2. What is the maximum tool diameter that this machine can process?

The machine can process tools with a maximum diameter of 20mm.

3. What is the maximum length of tools that can be handled by the grinder?

The maximum tool length that can be processed is 200mm.

4. Can this machine handle automatic loading and unloading?

Yes, the machine can be optionally equipped with a 3-axis automatic loading system for full-automatic production.

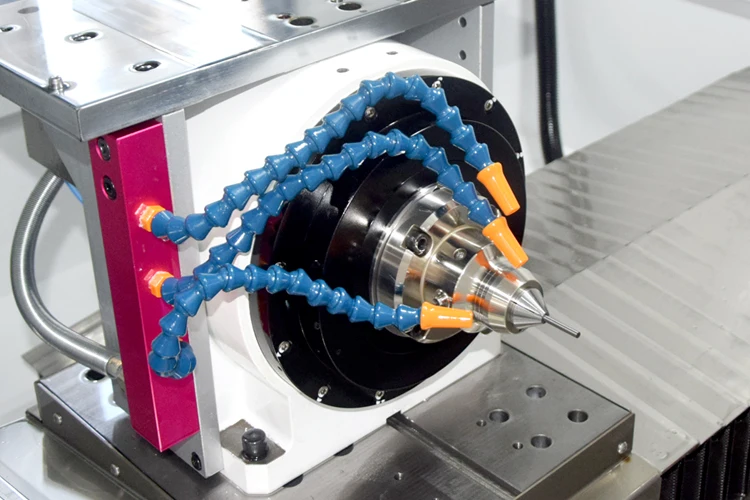

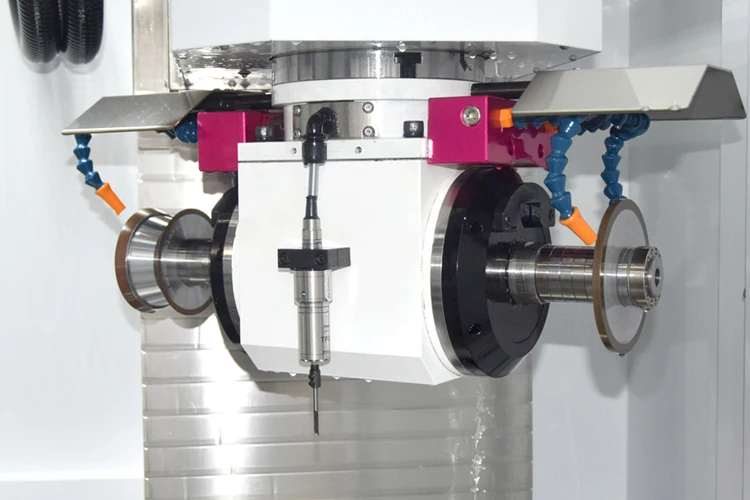

5. What are the key features of the grinding spindle?

The grinding spindle features an 11KW high-power precision direct drive and can install 4-8 pieces of flange grinding wheels.

6. What is the maximum processing workpiece weight?

The maximum workpiece weight that the machine can handle is 10KG.

7. What type of CNC system does the QD560 utilize?

The QD560 uses the SYNTEC 210MA-5E CNC system.

8. What is the power requirement for this machine?

The machine operates on an AC 380V, 50HZ, 3-phase power supply.

9. How precise is the machining process?

The machine has a radial runout of less than or equal to 0.005mm for both the workpiece spindle and grinding head spindle.

10. What is the grinding head spindle rotation speed?

The grinding head spindle rotation speed can vary from 0 to 8000rpm.

11. What is the function of the air cylinder in this machine?

The air cylinder provides clamping force, which can be adjusted in the range of 800-1000kg.

12. What materials can the grinding wheels be made of?

The grinding wheels can be made of CBN or diamond, with sizes ranging from Φ50 to Φ200mm.

13. What is the travel speed of the linear axes?

The linear axes have a quick travel speed of 15m/min.

14. What are the dimensions and weight of the machine?

The machine dimensions are 1700×1520×2100mm and it weighs 4 tons.

15. Does the machine come with a warranty?

Please consult the supplier for specific warranty details and terms regarding the Horizontal CNC Cutter Grinders.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals