B21, China Town Mall, Midrand

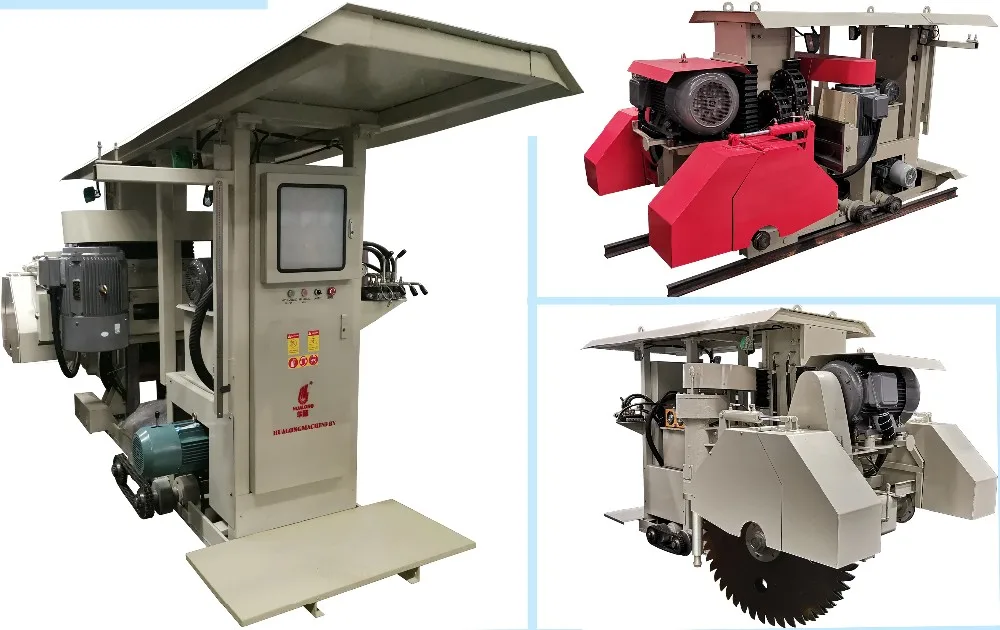

HKSS-1400 Limestone quarry cut Laterite Red Stone Cutting Machine

- Section : Machinery

- Category : Construction Machinery

- SKU : 1600900926134

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 07 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the HKSS-1400 Limestone quarry cut Laterite Red Stone Cutting Machine used for?

The HKSS-1400 is designed for quarrying and cutting sandstone, limestone and laterite into building blocks.

2. What are the main technical specifications of the HKSS-1400?

Main specs: vertical motor 75 kW, horizontal motor 45 kW, rail motor 5.5 kW; moving speed 10–45 m/min; max cylinder lifting 700 mm; max cutting depth 520 mm; vertical blade diameter 1330 mm, horizontal blade diameter 600 mm, blade thickness 11.5 mm.

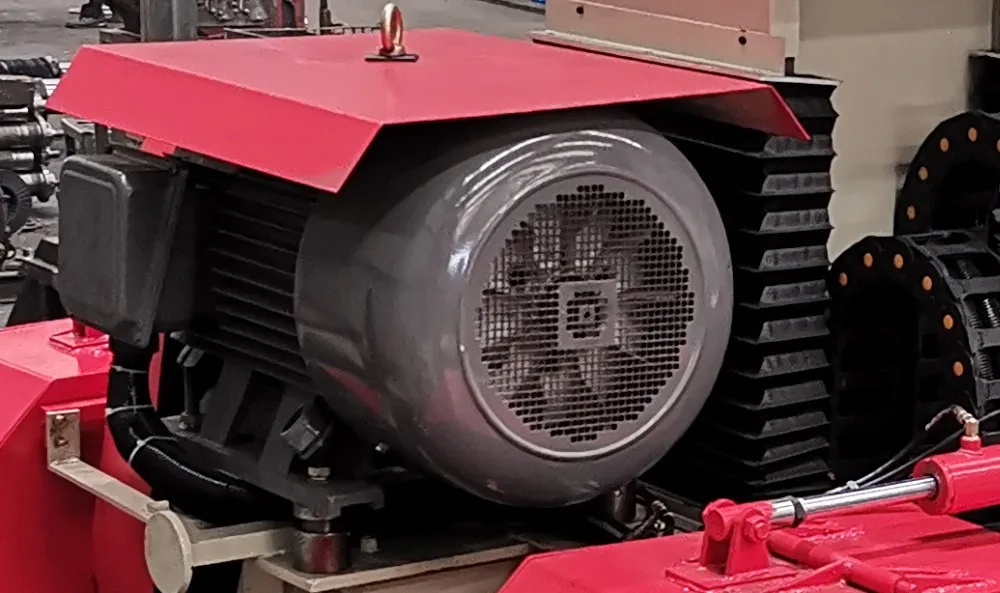

3. What type of motors does the machine use and what is their efficiency?

The main motors are three-phase asynchronous motors from brand XDDJ with an efficiency of 93.1%.

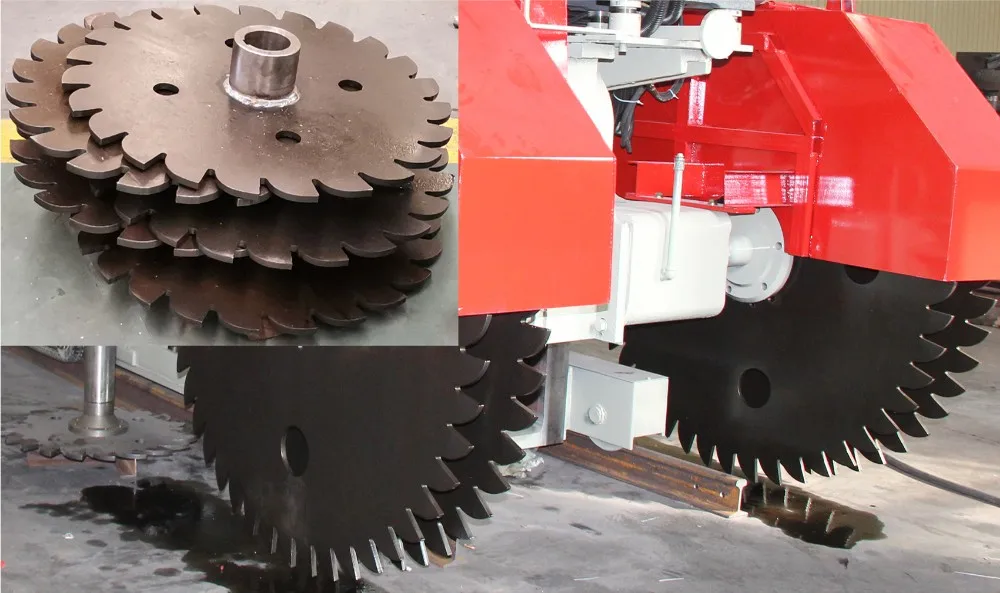

4. What are the blade and cutter head materials and properties?

Blades are made of Q460C manganese steel with heat treatment (high hardness, difficult to deform) with hardness up to HRC 52. Cutter heads use cemented carbide for high hardness, wear resistance, heat resistance and corrosion resistance.

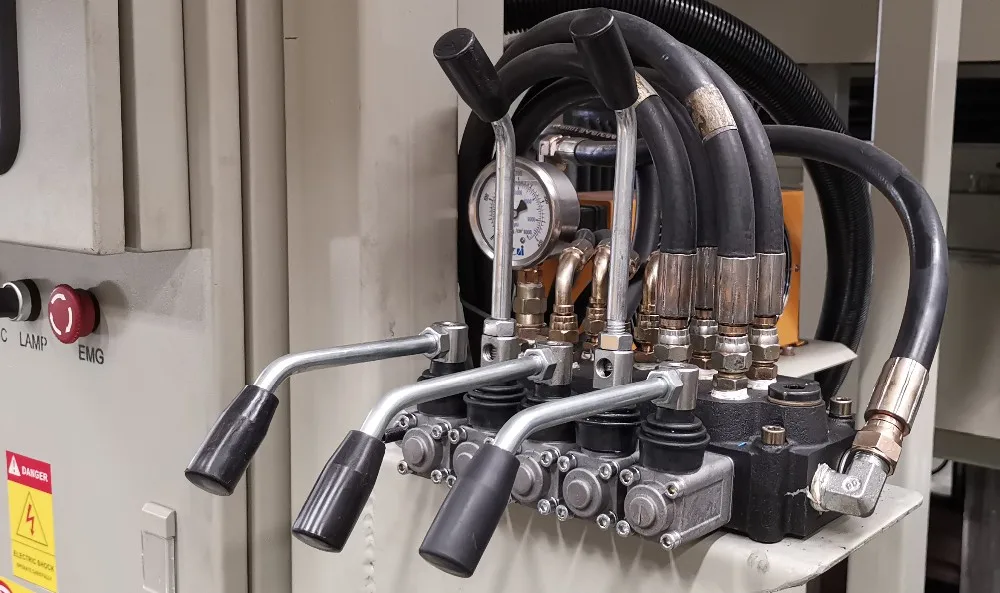

5. How is the machine controlled?

Control is via 5 joysticks that operate up/down movement, spindle up/down, left/right, and blade cover open/close. The operation interface is simple and easy to learn.

6. How many operators are required and how easy is it to operate?

Typically a single trained operator can run the machine; operators are usually able to use it effectively after a few hours of hands-on practice.

7. What are the machine's cutting capacity limits?

Maximum cutting depth per pass is 520 mm and the cylinder lifting range is 700 mm. Block dimensions (length/width) depend on quarry layout and number of passes—contact the supplier for custom sizing guidance.

8. What are the machine's movement and cutting speeds?

The carriage moving speed (forward and backward) ranges from 10 to 45 m/min. Cutting feed speeds should be set according to stone type and blade condition.

9. Which electrical components and brands are used on the power/operation panel?

Power connection and the operation panel use components from Siemens, Schneider and SANCH. The machine is CE quality certificated.

10. What safety and protection features does the machine include?

Features include blade covers (open/close via joystick) and robust structural guides for stable cutting. Operators should also use standard PPE (eye, ear, hand, respiratory protection), ensure guards are in place, and follow lockout/tagout and site safety procedures. For specific integrated safety features (e.g., emergency stop locations), confirm with the supplier.

11. What routine maintenance is recommended?

Recommend daily visual checks, lubrication of guideways as specified, periodic inspection of blades and cutter heads for wear, timely replacement of worn blades/carbide tips, and scheduled electrical and motor maintenance by qualified technicians.

12. Are spare parts and replacement blades available?

Spare blades, cutter heads and common wear parts are available—contact the manufacturer or authorized dealer for parts lists, lead times and part numbers.

13. What are the installation and power supply requirements?

The machine requires a suitable three-phase power supply sized to the motors (total nominal motor power ≈125.5 kW). Final voltage, frequency and supply configuration should be confirmed with the supplier and installed by a qualified electrician. Site foundations and crane/lifting arrangements should meet the supplier's installation requirements.

14. Is the HKSS-1400 certified for quality and safety?

Yes, the machine's control components and assembly are quality certificated by CE. For additional regional certifications or compliance documentation, contact the supplier.

15. How do I get pricing, warranty, delivery, training and installation support?

Contact the manufacturer or authorized dealer for quotations, warranty terms, delivery lead times, installation services and operator training packages. They can also provide detailed specifications, transport dimensions and on-site commissioning options.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading