B21, China Town Mall, Midrand

High speed stable quality air bubble film bag making machine

- Section : Machinery

- Category : Multi-Function Packaging Machines

- SKU : 1600167664235

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 04 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the High speed stable quality air bubble film bag making machine used for?

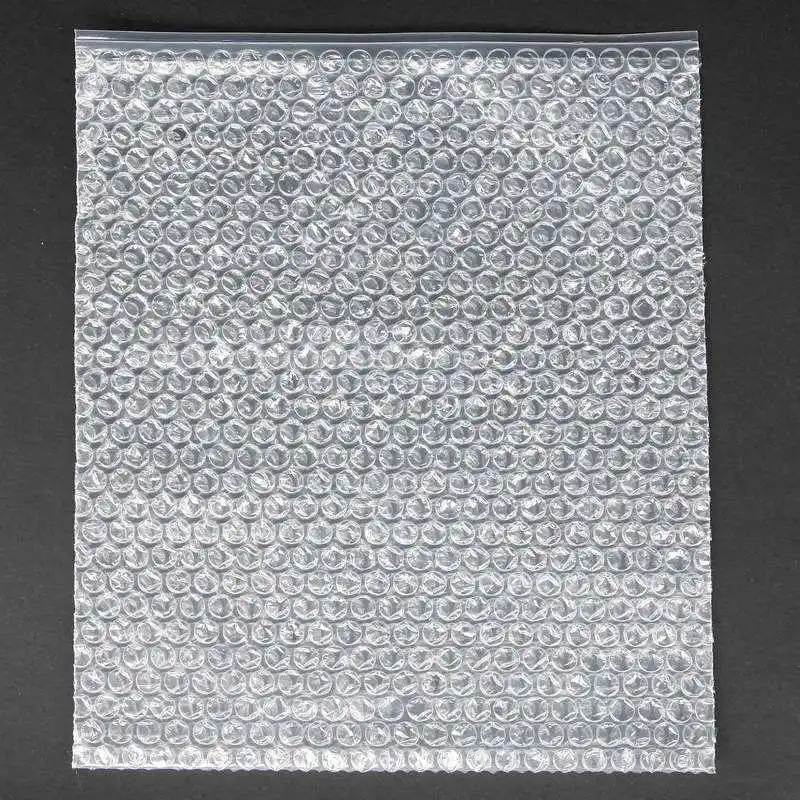

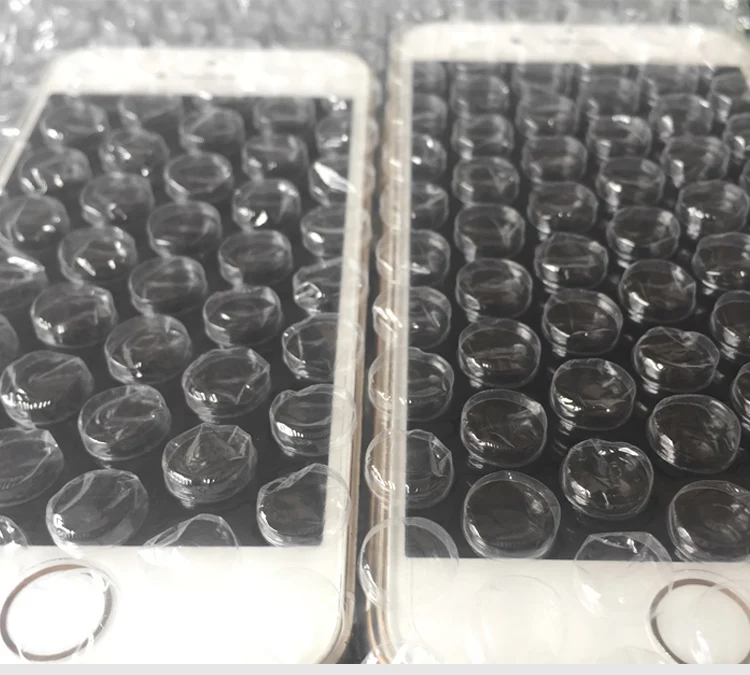

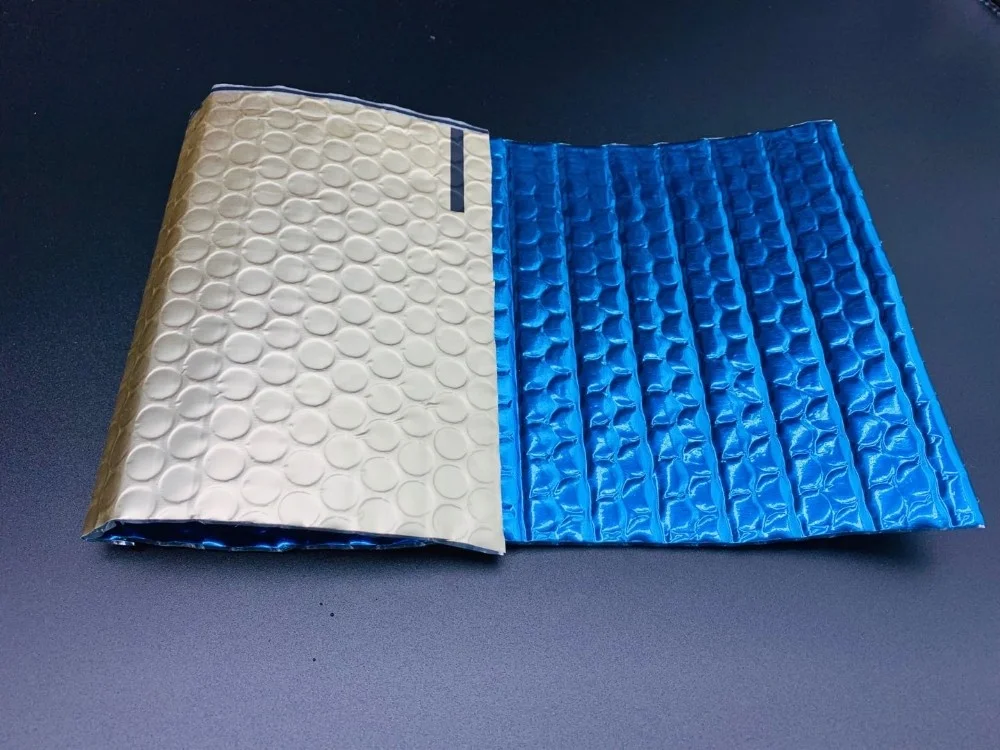

It produces air bubble film bags from PE bubble film (and laminated variants) with automatic folding, sealing and counting — suitable for protective packaging such as bubble mailers, padded bags and laminated multi-layer bubble film bags.

2. What output speed can I expect?

Maximum output depends on model, bag size and material. The machine can reach up to around 180 units/min under ideal, small-bag conditions; model ratings list typical ranges (for example PTZD-S3-1200: 20–150 units/min; PTZD-S3-1300: 20–130 units/min; PTZD-S3-1400: 20–130 units/min; PTZD-S3-1500: 20–120 units/min).

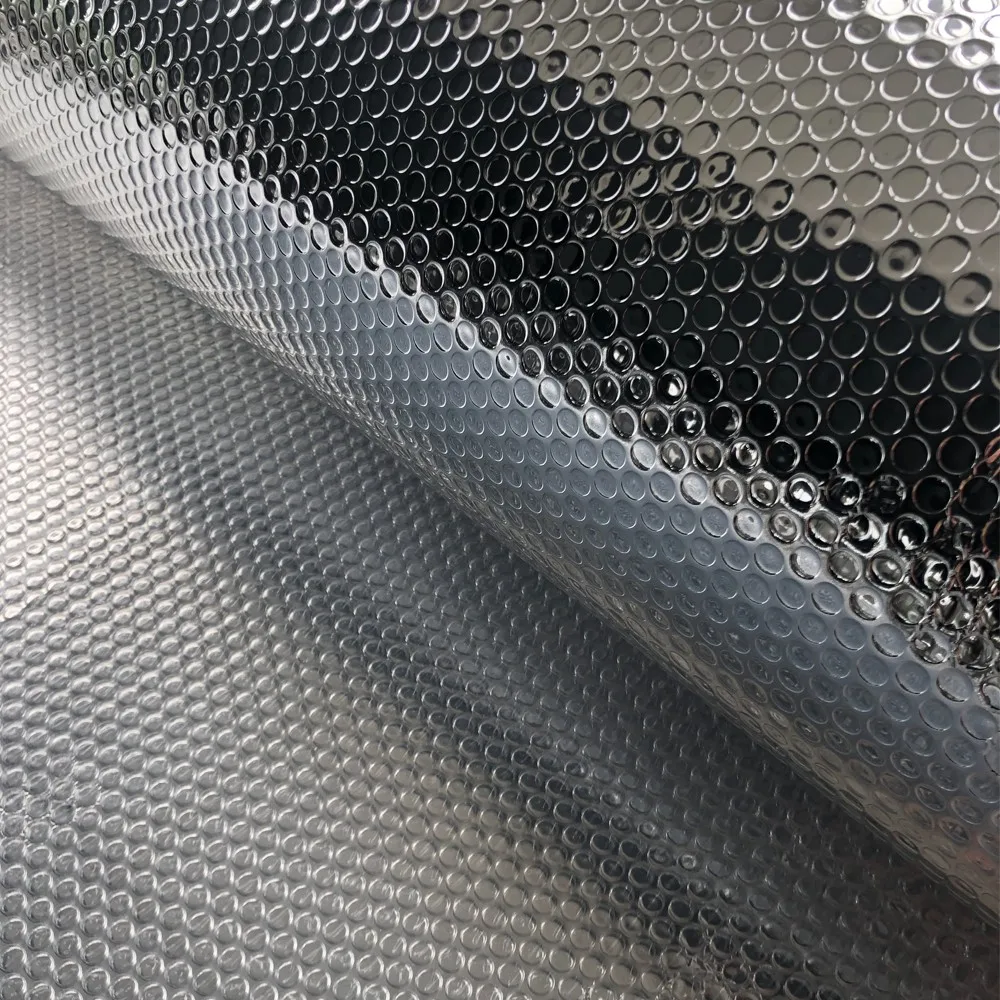

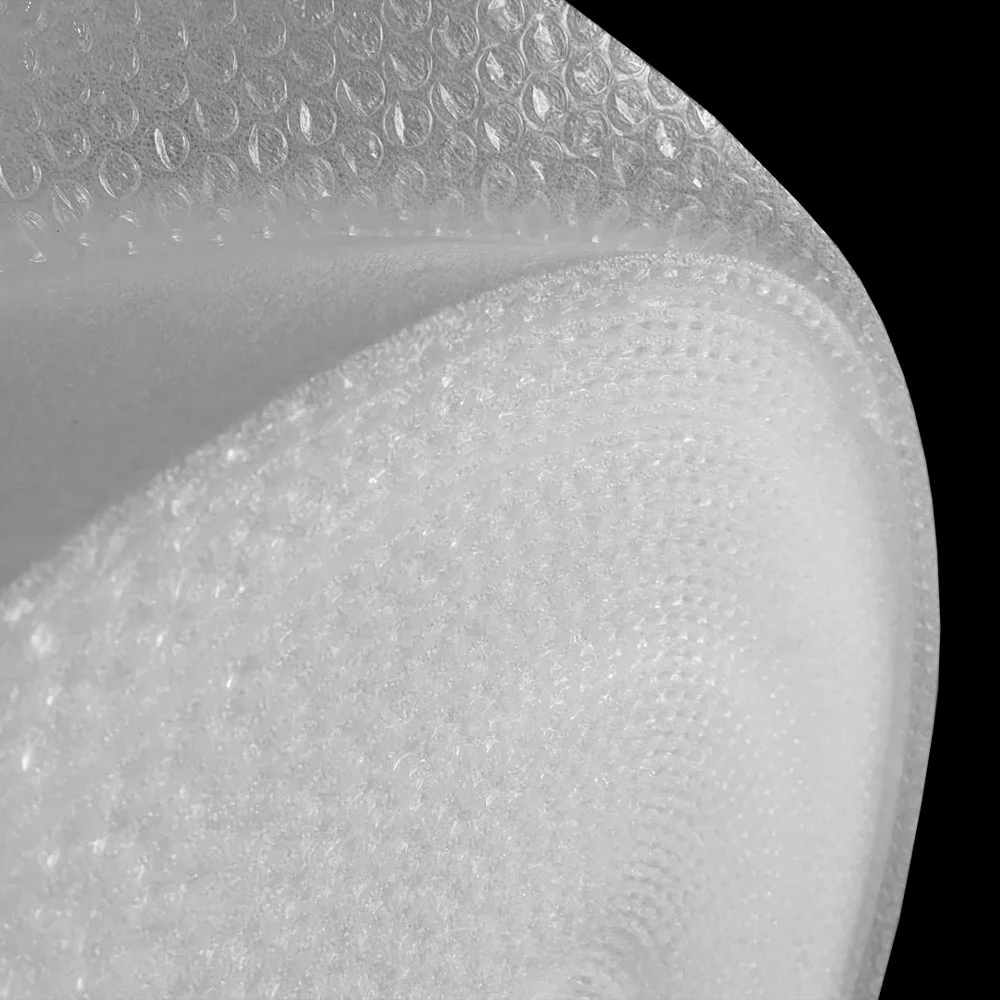

3. Which film materials are compatible with this machine?

Standard compatibility is PE bubble film. The machine also supports two- and multi-layer formats such as two-side-flat three-layer, kraft- or aluminum-laminated three/four/five-layer bubble films and EPE/PE foam laminated bubble film (confirm specific laminate types when ordering).

4. What bag sizes can the machine make?

Bag width range is approximately 50–990 mm. Available nominal bag lengths shown for the models include about 1150 mm, 1250 mm, 1350 mm and 1450 mm (model-dependent). Actual size limits depend on model and machine setup.

5. What sealing method does the machine use?

The standard configuration provides three-side sealing. The machine can be optionally upgraded with automatic four heated blades for four-side or alternative sealing processes.

6. What is included in the full machine set?

A full set includes an automatic bag number counter, an air bubble breaker, synchronous belts, triangular folding system and the sealing/station components for continuous bag making. Optional add-ons are available.

7. What optional upgrades are available?

Optional upgrades include automatic four heated blades, a glue sprayer, a 5 kW servo motor, bag number counting (if not standard) and stack conveying for easier packing and handling.

8. What are the power requirements?

Operation power varies by model and configuration. Please consult the detailed technical specification or contact the supplier with your chosen model and optional upgrades to get the exact kW and electrical requirements.

9. What are the machine dimensions and weight?

Dimensions and weight vary by model and configuration. The product family spans multi-meter lengths and machine weights in the tonne range (example weights shown in the data: approximately 2000–3000 kg depending on model). Ask the supplier for the exact L×W×H and weight of a given model.

10. How do I choose the right model for my production?

Select based on the maximum bag width and length you need, desired output (units/min), film type (single or multi-layer, laminated), and whether you need optional features such as four heated blades, glue sprayer or conveyor/stacking. Provide your production targets and film specification to the supplier for a recommendation.

11. Does the machine require special installation or operator training?

Yes — professional installation and commissioning are recommended. Suppliers typically offer on-site installation, commissioning and operator training to ensure proper setup, safety and optimal production.

12. What maintenance is required?

Routine maintenance includes cleaning sealing blades and folding areas, inspecting and replacing worn synchronous belts and blades, lubricating moving parts as recommended, and routine electrical and sensor checks. Follow the supplier’s maintenance schedule for best results.

13. Are spare parts and after-sales support available?

Spare parts (blades, belts, sensors, etc.) and after-sales support are normally available from the manufacturer or distributor. Confirm lead times, warranty terms and spare-part availability before purchase.

14. What safety features does the machine have?

The machine is designed for industrial production and can be equipped with standard safety protections such as guarding, emergency stop(s) and interlocks. Exact safety features depend on the configuration and local safety regulations — confirm with the supplier.

15. Can the machine handle laminated and multi-layer bubble films?

Yes. The line supports a variety of laminated and multi-layer bubble films (kraft-laminated, aluminum-laminated, four- or five-layer constructions, EPE/PE foam laminated films). Verify compatibility for your specific laminate thickness and adhesive layers when ordering.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading