B21, China Town Mall, Midrand

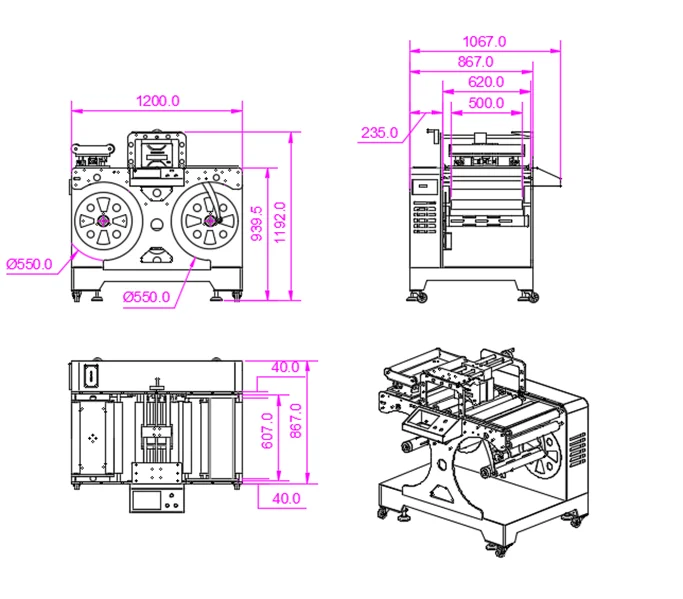

High speed label rewinding machine

- Section : Machinery

- Category : Industrial Machinery

- SKU : 1600460610242

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 22 Mar, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What industries can the High Speed Label Rewinding Machine be used in?

The machine is suitable for various industries including pharmaceutical, printing, packaging, food, cosmetics, seed, and pesticide industries.

2. What are the core components of the High Speed Label Rewinding Machine?

The core components include a PLC, touch screen, bearings, gearbox, motor, and gears.

3. What are the key features of this machine?

Key features include friction paging, energy saving, long service life, vacuum adsorption (optional), low noise level, high accuracy, high scalability, high safety level, competitive price, high reliability, automatic operation, sustainable design, high productivity, and multifunctional capability.

4. Does the machine support double sheet detection?

Yes, the High Speed Label Rewinding Machine offers optional double sheet detection to enhance functionality.

5. Is the High Speed Label Rewinding Machine energy efficient?

Yes, it features an energy-saving design that contributes to lower operational costs and sustainability.

6. How does the vacuum adsorption feature work?

The vacuum adsorption feature helps in securely holding the labels during the rewinding process, ensuring a high level of precision and reducing the risk of damage.

7. What is the noise level of the machine during operation?

The High Speed Label Rewinding Machine is designed to operate at a low noise level, making it suitable for various working environments.

8. Can this machine operate automatically?

Yes, the machine has automatic operation capabilities, which enhances efficiency and reduces labor requirements.

9. What is the expected service life of the machine?

The machine is designed for a long service life, thanks to its robust construction and high-quality components.

10. Is the machine easy to operate?

Yes, it features a user-friendly touch screen interface that simplifies the operation process.

11. What kind of maintenance does the machine require?

Regular maintenance includes checking and replacing gears, bearings, and ensuring the cleanliness of the machine to prevent any operational issues.

12. What is the production capacity of the High Speed Label Rewinding Machine?

The machine is designed for high productivity, capable of handling large volumes of labels efficiently.

13. Is the machine suitable for small batch production?

Yes, the high scalability of the machine makes it suitable for both small and large batch production.

14. What safety features does the machine include?

The machine is equipped with high safety levels to ensure safe operation and minimize risks during use.

15. How does the competitive pricing of this machine compare to others in the market?

The High Speed Label Rewinding Machine offers competitive pricing while maintaining high reliability and performance, making it a great investment.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals