B21, China Town Mall, Midrand

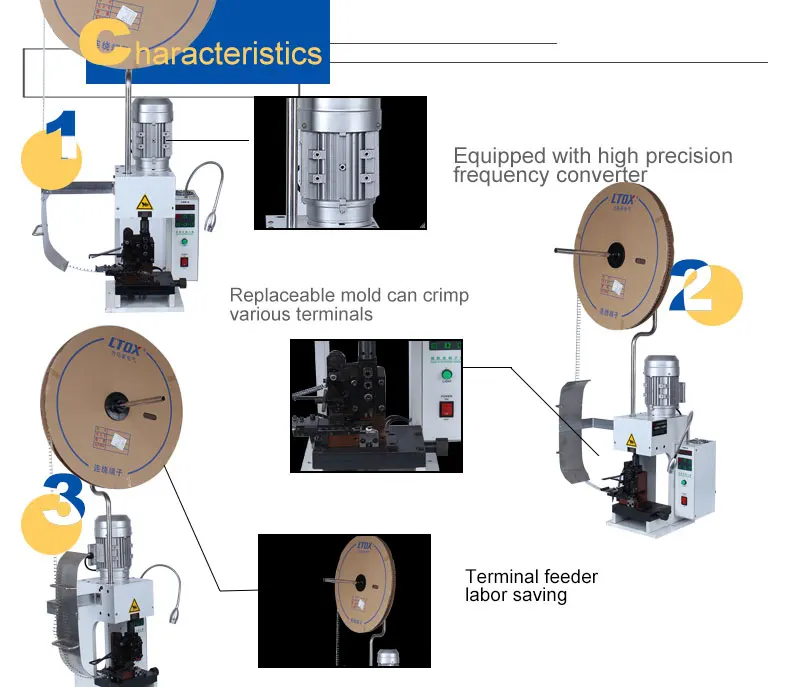

HC-3T Semi-Automatic Wire Terminal Crimp Machine

- Section : Machinery

- Category : Metal & Metallurgy Machinery

- SKU : 62056476057

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 21 Mar, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the HC-3T Semi-Automatic Wire Terminal Crimp Machine used for?

The HC-3T is designed for efficient crimping of wire terminals in cable manufacturing environments. It performs high-pressure crimps for a variety of terminal types to increase productivity in semi-automatic production lines.

2. What are the key specifications (size, weight, power) of the HC-3T?

Outer dimensions: L390mm × W300mm × H710mm. Weight: 75 kg. Power supply: 220V. Power consumption (220V): 750W.

3. What crimping force and conductor sizes does the HC-3T support?

The machine provides a standard 3-ton (nominal 3000 kg) crimping capacity. It supports conductor cross sections from 0.1 mm² up to 6 mm² (approximately AWG 26 to AWG 10).

4. How fast can the HC-3T crimp?

The HC-3T has a high theoretical crimping rate (advertised up to 45 cycles per minute). Practical throughput depends on operator handling, terminal type and cycle setup; the stated typical process capability is around 5 pieces per minute for realistic production conditions.

5. What stroke and closing height adjustments are available?

The programmable stroke can be set up to a maximum of 30 mm. Maximum closing height is 150 mm, with fine closing-height adjustment increments of 10 mm.

6. Is the HC-3T fully automatic or semi-automatic? How is it operated?

The HC-3T is semi-automatic: an operator typically feeds the wire/terminal and the machine performs the crimp cycle. Controls are user-friendly and designed to minimize required training. Specific actuation methods (push-button, foot pedal, etc.) should be confirmed with the supplier or in the configuration you purchase.

7. What types of terminals and wires are compatible with this machine?

The HC-3T is suitable for a wide range of crimp terminals and wire types that fall within the conductor size range of 0.1–6 mm². For specific terminal geometries (ferrules, ring, spade, bootlace, etc.), appropriate crimp tooling/dies are required — the supplier can recommend or supply matching tooling.

8. Are crimping dies/tooling included and are they replaceable?

Crimp dies/tooling are typically replaceable to suit different terminal profiles. Whether tooling is included varies by purchase package; contact your supplier to confirm included tooling and options for additional or custom dies.

9. What maintenance is required to keep the HC-3T running reliably?

Regular maintenance typically includes routine cleaning, periodic inspection of dies and wear components, lubrication of mechanical parts as recommended by the manufacturer, and checking electrical connections. Follow the supplier’s maintenance checklist for interval specifics and replacement parts.

10. What safety precautions should operators follow when using the HC-3T?

Follow standard machine safety procedures: disconnect power before servicing, use proper personal protective equipment, keep hands and loose clothing clear of the tooling area during operation, and ensure operators are trained on safe use. Consult the machine manual or supplier for any machine-specific safety features and instructions.

11. Can the HC-3T be serviced or supported overseas?

Yes. The product description states engineers are available to assist with overseas machinery service and integration. Contact the supplier to arrange service, installation, and remote or on-site support options.

12. Can the HC-3T be adapted for 110V power supplies or other voltages?

The standard specification lists 220V. For other voltages (e.g., 110V), you should contact the manufacturer or supplier — they can advise on transformer/convertor options or whether a different model/configuration is available for your region.

13. What is the expected lifespan and durability of the machine?

The HC-3T is described as having a robust design and is built to endure heavy usage. Actual lifespan depends on usage intensity, maintenance, and operating conditions. For long-term reliability plan routine maintenance and use genuine replacement parts recommended by the supplier.

14. Is there a warranty or spare-parts availability?

Warranty terms and spare-parts availability can vary by supplier and purchase agreement. Contact the seller or manufacturer for exact warranty coverage, spare parts lead times, and recommended spare-parts kits.

15. How do I get help selecting the right configuration or integrating the HC-3T into my production line?

The manufacturer/supplier offers engineering support for customized solutions and overseas service. Provide details about your terminals, wire sizes, desired throughput and any integration requirements so their engineers can recommend tooling, configuration, and installation options.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals