B21, China Town Mall, Midrand

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 11 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the Gold Ore Ball Mill Machine used for?

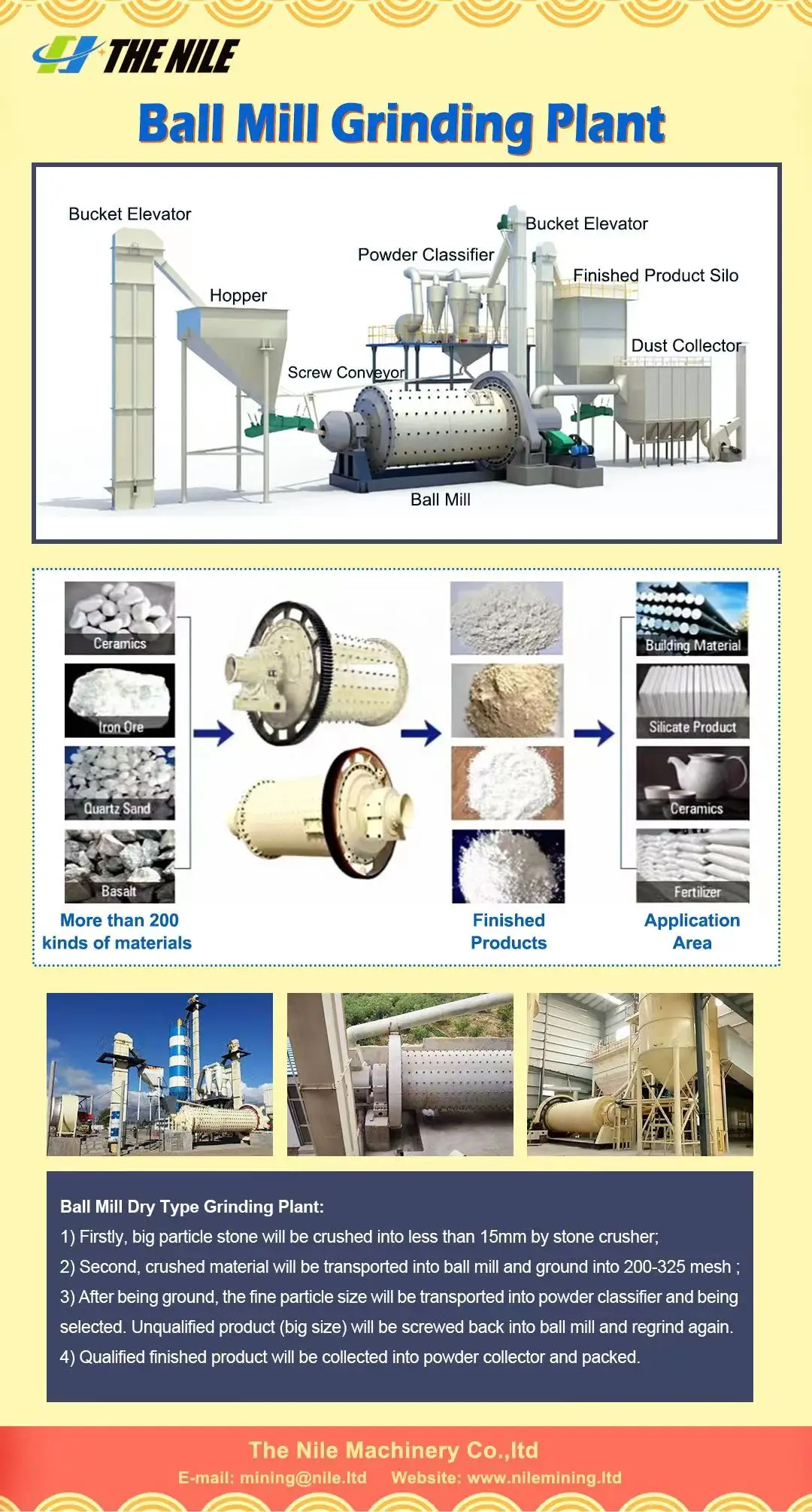

It is used to grind gold ore, stones and other minerals into fine powder for mining, mineral processing and construction applications such as ore liberation, grinding for flotation, leaching or producing construction-grade powder.

2. Which materials can this ball mill process?

Typical materials include gold ore, iron ore, copper ore, limestone, quartz, feldspar and other hard or brittle minerals. It can be configured for wet or dry grinding depending on the material and downstream process.

3. What milling modes are supported — wet or dry?

Both wet and dry milling modes are supported. Wet milling is commonly used in mineral processing for higher efficiency and better particle dispersion; dry milling is used when moisture must be avoided or for specific downstream uses.

4. What particle size / fineness can the machine achieve?

Final particle size depends on feed size, milling time, grinding media and classifier. It can produce a wide range from coarse powder to very fine powder — commonly in the range of about 80–325 mesh (and finer with extended milling or additional classification). Exact fineness should be specified for model selection and testing.

5. How much material can the mill process (capacity / throughput)?

Throughput depends on model size, feed size, desired fineness and operating parameters. Capacities range from small pilot-scale (hundreds of kg/day) to large industrial systems (several tons/hour). Provide your target capacity so we can recommend an appropriate model.

6. What are the machine's power and energy consumption characteristics?

The machine is engineered for high efficiency and lower energy consumption compared with older designs. Actual power draw depends on motor rating, load and operating conditions. We can provide estimated power consumption for a given configuration during quotation.

7. Are dimensions and specifications customizable?

Yes. Length, diameter, motor power, lining type, discharge method and auxiliary equipment can be customized to meet site constraints and process requirements.

8. What are the main wearing parts and how often do they need replacement?

Primary wear parts are shell liners, grinding media (balls), inlet/outlet liners and seals. Replacement frequency depends on ore abrasiveness and operating hours; routine inspection and scheduled liner/ball replacement are recommended to maintain efficiency.

9. What maintenance is required to keep the machine running reliably?

Regular maintenance includes checking and tightening bolts, monitoring and replacing liners and grinding media, lubricating bearings and gearboxes, inspecting seals and couplings, and monitoring vibration/temperature. A preventive maintenance schedule is recommended.

10. What installation requirements does the machine have?

Installation typically requires a solid concrete foundation, appropriate crane/hoisting for positioning, electrical power supply sized to the motor, and space for accessories (feed system, classifier, dust collector). Detailed installation drawings and support are provided with the equipment.

11. Does the machine comply with safety and quality standards?

Yes. The product meets ISO and CE standards. Standard safety features include protective guards, emergency stop, and grounding. Additional safety and monitoring options are available on request.

12. Can the mill be integrated into a complete processing line?

Yes. It can be supplied as a stand-alone unit or integrated with feeders, classifiers (cyclones or screens), conveyors, slurry pumps, dust collectors and control systems to form a complete grinding circuit.

13. How is dust and noise managed?

Dust control options include enclosed housings, bag filters, cyclones and wet suppression. Noise reduction can be achieved with soundproof enclosures and acoustic panels. Specific mitigation measures are recommended based on site requirements.

14. What comes with the purchase — spare parts and after-sales service?

Standard packages typically include the main mill, motor, standard liners, a basic control panel and documentation. Spare parts kits and on-site commissioning, operator training and maintenance support are available. Extended service agreements can be arranged.

15. How do I choose the right model and get a quotation?

Provide the following: material type and abrasiveness, feed size, desired final fineness, required capacity (t/h), available power supply and any site constraints. We can perform lab or pilot testing on samples to recommend the best model and provide a detailed quote.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading