B21, China Town Mall, Midrand

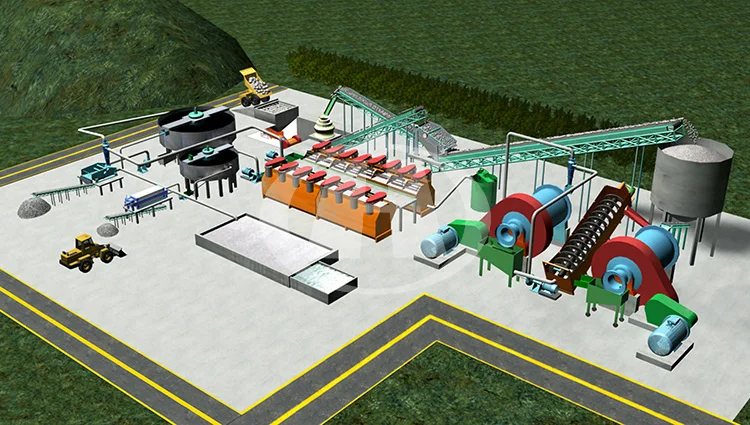

Gold Cip Production Line Gold Mining Machine

- Section : Machinery

- Category : Industrial Machinery

- SKU : 62245860556

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 22 Mar, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the Gold Cip Production Line Gold Mining Machine?

The Gold Cip Production Line Gold Mining Machine is a complete set of equipment designed for gold mining processing, specifically utilizing the Carbon in Leach (CIL) process to extract gold efficiently.

2. What capacity does the Gold Cip Production Line support?

The production line can handle capacities ranging from 50 to 1000 tons per day (tpd) depending on your operational needs.

3. What types of ores can be processed with this equipment?

In addition to gold ore, the equipment can also be used for flotation of copper, lead, zinc, fluorite, feldspar, graphite, tungsten, and other metals and non-metal ores.

4. What are the main components of the Gold Cip Production Line?

The main components include a feeder, jaw crusher, cone crusher, vibrating screen, belt conveyors, ball mill, spiral classifier, hydro cyclone, thickener, leaching tanks, electrowinning and desorption device, and a gold smelting furnace.

5. How does the gold extraction process work?

The process involves crushing and grinding the ore, followed by leaching it with cyanide to extract gold. The gold is then recovered through electrowinning and smelting.

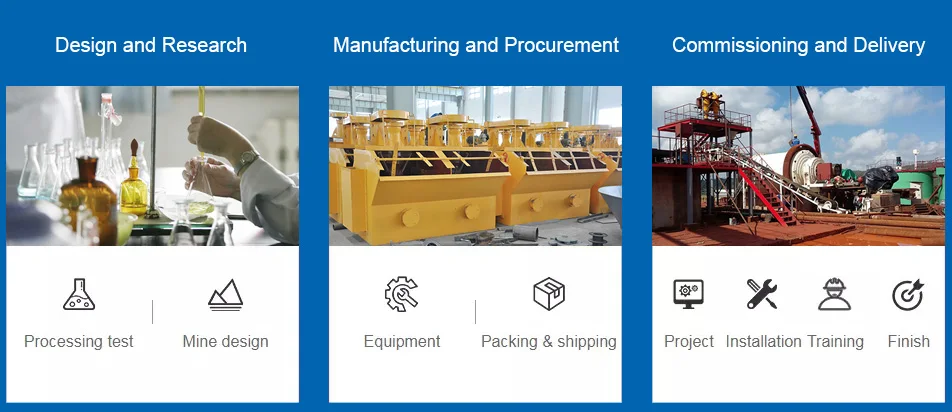

6. What advantages does Hongji offer as a manufacturer?

Hongji has over 18 years of production experience, a dedicated R&D team, a comprehensive after-sales service system, and offers customized solutions tailored to client needs.

7. Is there a training program available for operating the machinery?

Yes, we provide training for operators as part of our service, ensuring they are well-equipped to handle the machinery safely and effectively.

8. Can Hongji assist with the design and layout of the production line?

Absolutely! We offer flowchart designing and layout designing services to create an optimal setup for your gold mining operations.

9. What is the recovery rate of gold using this production line?

The gold mine utilizing our production line boasts a high recovery rate, ensuring efficient extraction of gold with minimal waste.

10. What type of after-sales support is available?

We provide a complete after-sales service, which includes technical consultation, troubleshooting, and maintenance assistance to ensure your production runs smoothly.

11. How can I get a customized solution for my mining needs?

You can contact us directly to discuss your specific requirements, and our team will work with you to develop a tailored solution that meets your operational goals.

12. Is the Gold Cip Production Line environmentally friendly?

We prioritize sustainability and implement technologies that minimize environmental impact while maximizing gold recovery efficiency.

13. What are the installation requirements for the production line?

Installation requirements will depend on the specific layout and site conditions. Our team will assist with erecting and commissioning the equipment on-site.

14. Are there financing options available for purchasing the equipment?

We can discuss various financing options and packages to accommodate your budget and investment plans.

15. How long does it take to set up the production line?

The setup time varies based on the complexity of the installation and equipment. Our team will provide a timeline after assessing your specific project.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals