B21, China Town Mall, Midrand

Fully Automatic PVC Edge Banding Machine: Streamlining Wooden Furniture Processing

- Section : Machinery

- Category : Woodworking Machinery

- SKU : 62325797529

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 05 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the Fully Automatic PVC Edge Banding Machine used for?

It's designed to automatically apply PVC edge banding to wooden furniture panels (e.g., MDF, particle board, solid wood edges), trimming and polishing the edges to produce a finished, factory-quality look.

2. What banding tape thickness and width does the machine support?

Banding tape thickness: 0.4–3 mm. Banding tape width: 10–60 mm.

3. What workpiece dimensions can the machine handle?

Workpiece thickness: 10–60 mm. Minimum workpiece length: ≥100 mm. Minimum workpiece width: ≥50 mm.

4. What is the feeding speed (production speed) of the machine?

Feeding speed is adjustable between 10–23 m/min. Production throughput depends on panel sizes; at 20 m/min the machine applies about 1,200 m of edge banding per hour in continuous running.

5. What are the main power and motor specifications?

Heating power: 1.5 kW. Feeding motor: 2.2 kW. Glue spreading motor: 0.37 kW. End trimming motors: 0.55 kW × 2. Fine trimming motors: 0.75 kW × 2. Rough trimming motors: 0.75 kW × 2. Corner trimming motors: 0.5 kW × 2. Polishing motors: 0.37 kW × 2.

6. What are the machine dimensions, weight and packing size?

Overall dimension: 4700 × 750 × 1500 mm. Packing size: 5000 × 1000 × 1600 mm. Net weight (N.W.): 1600 kg. Gross weight (G.W.): 1870 kg.

7. What air supply is required?

Required air pressure is 0.8 MPa (approximately 8 bar). Ensure a stable, dry compressed air source sized to supply the machine's pneumatic components.

8. How does the glue system work and is it easy to clean?

The glue mechanism uses four irregular cylindrical pinch rollers to firmly press the band to the panel, plus board preheating for better adhesion. The glue pot is nonstick for easy cleaning and minimal residue. Automatic oiling equipment is also included.

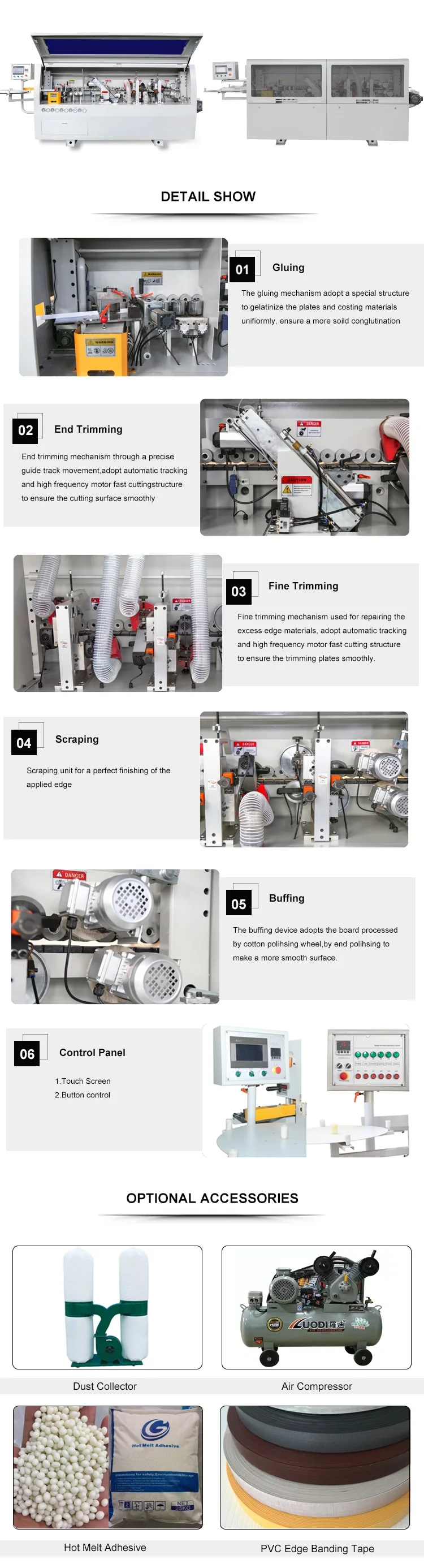

9. What trimming and finishing units are included?

Includes end trimming with precise guide-track movement and auxiliary pinch roller for narrow boards; rough trimming and fine trimming (six-edge knives and linear guideways) for smooth cuts; scraping unit with dust-collecting pipe; and buffing/polishing with cotton polishing wheels for smooth surfaces.

10. Does the machine provide dust control?

Yes. It features a dust-proof plate along the edge banding process and a scraping unit with a dust-collecting pipe to reduce airborne dust and make cleanup easier.

11. What controls and user interface does the machine have?

The machine is equipped with an easy-to-operate control panel for adjusting feeding speed, temperature and process parameters. Settings are accessible to operators and intended for straightforward daily use.

12. What safety features are included?

Safety features include dust-proof protection plates, pneumatic components (SMC cylinders and throttles) for stable, low-noise operation, and standard emergency stop and guarding to protect operators during operation.

13. What maintenance is required to keep the machine running well?

Regularly clean the glue pot and glue rollers, check and replace trimming knives and polishing wheels as needed, lubricate guide rails and moving parts per schedule, inspect pneumatic lines and filters, and keep dust collection functioning.

14. What materials and panel types are compatible?

Primarily designed for PVC edge banding on wooden furniture panels such as MDF, particleboard and solid wood edge banding. Also compatible with most standard PVC banding tapes within the specified thickness/width ranges.

15. What should I consider for installation and site requirements?

Provide a flat, level floor able to support the machine weight, adequate electrical supply matched to motor ratings, stable compressed air at 0.8 MPa, sufficient space for loading/unloading and ventilation, and access for dust extraction. Professional installation and commissioning are recommended.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading