B21, China Town Mall, Midrand

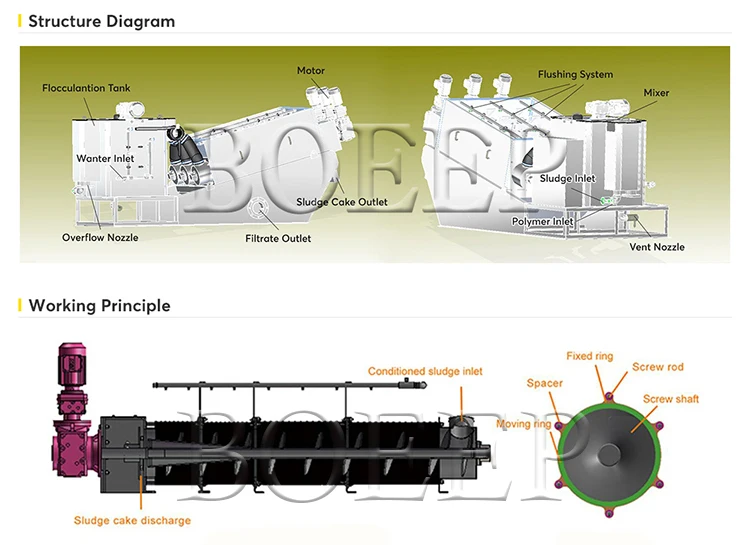

Fully Automatic DAF Sludge Stainless Steel Screw Press Dewatering Machine - Municipal Waste Water Treatment Plant

- Section : Machinery

- Category : Waste Treatment Machinery

- SKU : 1601124797090

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 05 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the main function of the Fully Automatic DAF Sludge Stainless Steel Screw Press Dewatering Machine?

The main function of this machine is to treat wastewater by efficiently dewatering sludge, reducing its volume and making waste disposal easier for municipal wastewater treatment plants.

2. What materials are used in the construction of this machine?

The machine is constructed from high-quality SS304/316 stainless steel, which is corrosion-resistant and durable, ensuring long-lasting performance even in harsh environments.

3. What is the treating capacity of this dewatering machine?

The machine can handle a sludge flow treating capacity ranging from 0.14m³/h to 55m³/h and a DS treating capacity of 5-650kgds/h.

4. How does the machine ensure precise moisture control?

The outlet cake moisture content can be controlled to range from 75% to 85%, which ensures that the dewatered sludge is easy to manage.

5. Is this machine energy efficient?

Yes, the Fully Automatic DAF Sludge Dewatering Machine is designed for high performance with low energy consumption, helping to reduce operating costs.

6. What kind of maintenance is required for this machine?

The machine requires minimal maintenance due to its robust design and high-quality components, making it cost-effective to operate.

7. Can this machine operate continuously?

Yes, the machine is capable of working 24/7, making it suitable for continuous operations in wastewater treatment plants.

8. What certifications does this machine have?

The machine is certified with SGS, CE, and ISO 9001 standards, meeting global industry standards for safety and performance.

9. Does the machine require manual control?

No, the machine features fully automatic operation, which reduces the need for manual control and enhances overall operational efficiency.

10. What are the advanced components used in this machine?

The machine features high-quality components from trusted brands, including SEW, NORD, Schneider, and Omron, ensuring reliable performance.

11. Is the machine suitable for all types of sludge?

Yes, the machine is suitable for dewatering various types of sludge, including those rich in oil and grease.

12. What is the protection level of the machine?

The machine has a protection level of IP55, offering protection against dust and water, ensuring reliable operation in tough conditions.

13. How is quality control ensured for this machine?

Quality control is ensured through video outgoing inspection and a machinery test report, guaranteeing that all machines meet strict quality standards.

14. What is the noise level during operation?

The machine operates with minimal noise, making it suitable for environments where noise reduction is important.

15. What are the benefits of using this dewatering machine?

Key benefits include low energy and water consumption, minimal polymer consumption, no need for sludge thickening, and low operational costs.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading