B21, China Town Mall, Midrand

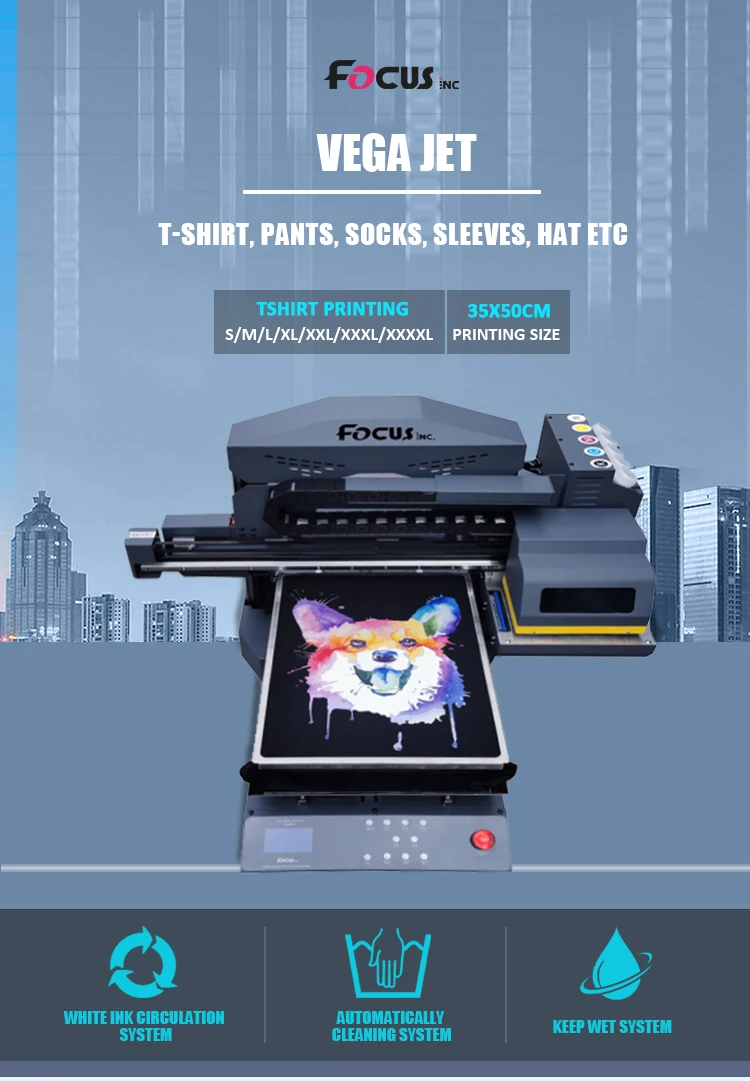

Focusinc A3 DTG Printer Direct Inkjet Digital Printer T shirts Printer

- Section : Consumer Electronics

- Category : Digital Printers

- SKU : 1600269985882-1712845324

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 30 Mar, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the maximum printable area of the Focusinc A3 DTG Printer?

The Focusinc A3 DTG Printer is designed for A3-sized prints. The printable area is approximately A3 dimensions (roughly 300–330 mm x 420–480 mm) depending on platen size and carriage limits. Exact usable area depends on the supplied platen and any fixture accessories.

2. What types of inks does this DTG printer use?

It uses textile-specific water-based pigment inks (CMYK plus white) formulated for direct-to-garment printing. These inks are designed for good color vibrancy and wash fastness when used with proper curing and pretreatment.

3. Can it print on dark garments, and is pretreatment required?

Yes — the printer can print on dark garments. For best opacity and color fidelity on dark fabrics, a white underbase is typically printed first and a pretreatment solution applied to the garment beforehand. Pretreatment improves ink adhesion and reduces bleeding.

4. What fabrics are compatible with the printer?

It works best on natural fibers such as 100% cotton and high-cotton blends. Polyester and performance fabrics can be printed but may require specialized inks or processes and can yield different hand-feel and durability. Always test on your specific fabric and follow ink manufacturer guidelines.

5. What resolution and print quality can I expect?

The printer supports high-resolution printing suitable for detailed graphics and photos. Typical DTG resolutions up to 1440 dpi are supported via the included RIP software, providing photographic-quality output depending on image preparation and garment pretreatment.

6. How fast is the Focusinc A3 DTG Printer?

Print speed depends on print mode, coverage, and whether a white underbase is used. Light-shirt prints can take under a minute in fast modes; dark-shirt prints with white underbase take longer (often 1–3 minutes). Throughput varies with resolution and RIP settings.

7. What software and drivers are included and which operating systems are supported?

The printer typically ships with a Windows-compatible driver and RIP software for print layout, color management, and white underbase control. Windows 7/10/11 are commonly supported. Mac support may be limited; check with the vendor for native Mac or third-party RIP options.

8. How is white ink managed to prevent clogging and settling?

This model uses white-ink circulation or periodic agitation routines (depending on configuration) and built-in head maintenance/capping sequences to minimize settling and clogging. Regular maintenance flushing and following the recommended use cycles are important to maintain reliability.

9. What are the maintenance requirements?

Daily checks and head-clean cycles are recommended, plus regular platen cleaning and scheduled flushing when idle for extended periods. Replace consumables such as capping pads, filters, and waste ink pads according to the maintenance schedule. Follow the user manual for detailed maintenance procedures.

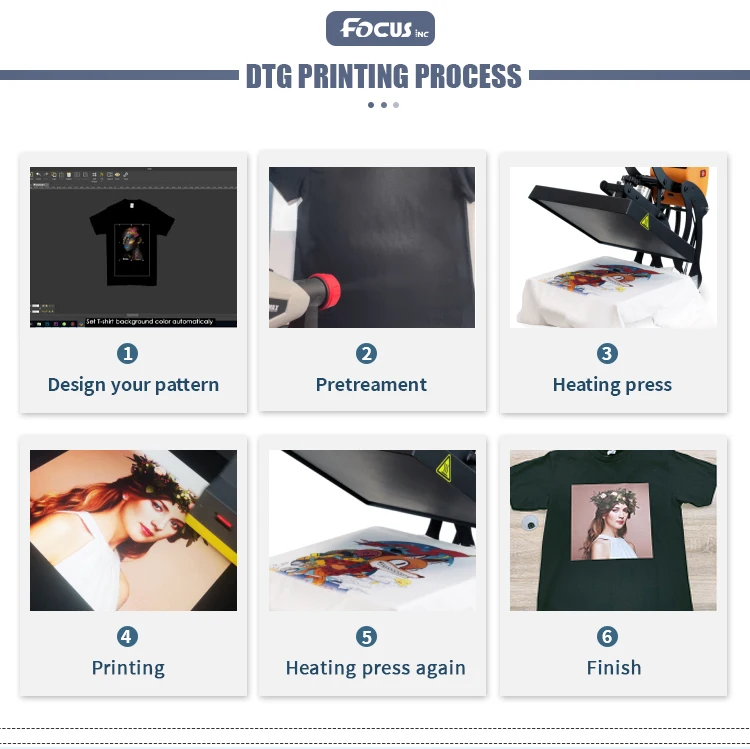

10. How do I cure the prints and what are the recommended curing settings?

Curing is required for wash-fastness. Typical methods are a heat press (e.g., 160°C / 320°F for 60–90 seconds) or a conveyor dryer set to the ink manufacturer’s recommended temperature/time. Exact settings depend on ink, garment, and dryer calibration — always follow the ink supplier’s curing guidelines.

11. What are the electrical and physical requirements for installation?

Install the printer on a stable, level surface in a well-ventilated area. Most benchtop A3 DTG units run on standard AC power (commonly 110–120V or 220–240V depending on the region); check the specific model label for voltage and amperage. Ensure adequate space around the unit for access and maintenance.

12. What consumables and spare parts should I expect to buy regularly?

Regular consumables include textile inks (CMYK + white), maintenance solution/flush, pretreatment fluid, platen blankets or tapes, capping station parts, wipers, and waste ink pads. Keep critical spares like extra printheads and platen accessories if you have high uptime requirements.

13. Is installation, training, and technical support available?

Vendors commonly offer installation assistance, on-site or remote training, and technical support packages. Check with your supplier for available options, costs, and warranty-covered support. Many suppliers also provide instructional materials and software setup help.

14. What warranty does the Focusinc A3 DTG Printer come with?

Warranty terms vary by supplier and region. A standard limited warranty (e.g., one year on parts and limited labor) is common, but confirm exact coverage, exclusions (consumables, printheads, misuse), and available extended warranty or service plans with the seller.

15. How do I get pricing, ordering information, and replacement parts?

Contact an authorized Focusinc dealer or the vendor’s sales team for current pricing, lead times, and ordering of replacement parts and consumables. Dealers can also provide quotes for bundled packages (printer, inks, pretreatment, and training).

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading