B21, China Town Mall, Midrand

Exclusive Milk Jam Soup And Honey Stick Sachet Filling Packing Machine

- Section : Machinery

- Category : Multi-Function Packaging Machines

- SKU : 1601009876930

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 05 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What products can the Exclusive Milk Jam Soup And Honey Stick Sachet Filling Packing Machine handle?

The machine is designed for liquids and semi-liquids such as water, milk, honey, soups, oils, sauces, jams and many personal-care liquids. For very high-viscosity products (thick jams or crystallized honey) we recommend discussing compatible filling pump options or heating with the supplier to ensure reliable dosing.

2. What is the maximum production speed?

Rated capacity is up to 80 bags per minute. Actual speed depends on bag length, film material, product viscosity, and operator settings.

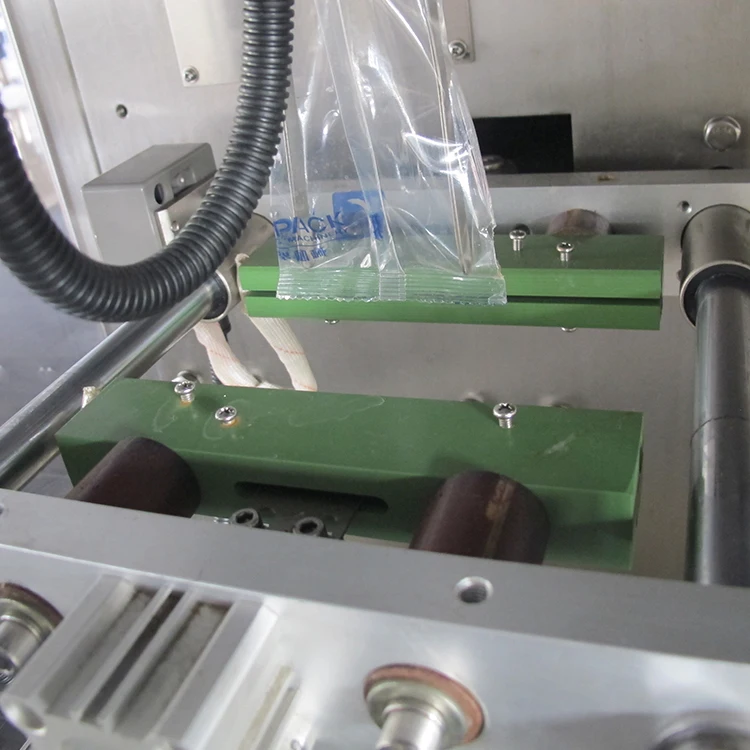

3. What bag sizes and bag types does it support?

Bag length (L) 50–200 mm and width (W) 60–150 mm. Supported bag styles include pillow bags, stand-up (gusset) bags, punching bags and vacuum bags (depending on film and tooling).

4. What packaging film specifications are required?

Packaging film width range is 140–320 mm with recommended film thickness of 0.04–0.09 mm. Film must be compatible with a vertical form-fill-seal process and the selected sealing type.

5. What materials contact the product and is it food safe?

Product-contact parts are manufactured from 316# or 304# stainless steel to meet food-safety requirements and facilitate cleaning.

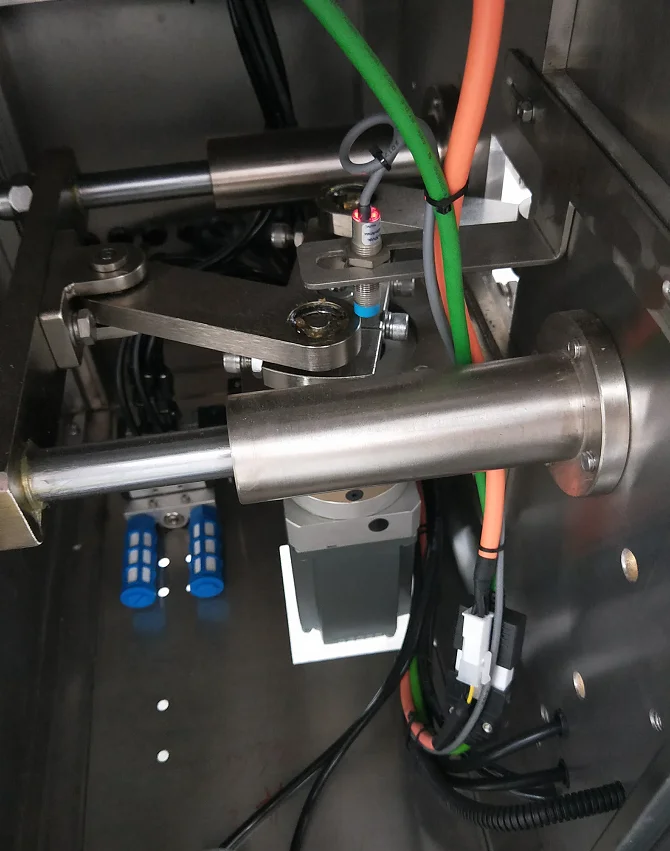

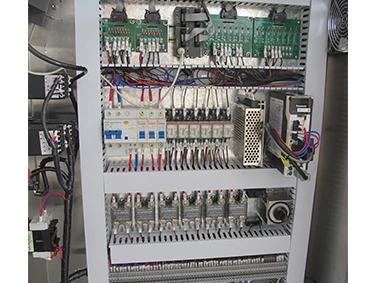

6. What control and motion systems are used?

The machine is available with Mitsubishi PLC or Siemens control systems and uses servo motor control for film drawing and horizontal sealing to ensure precise, synchronized operation and minimal film waste.

7. What are the machine dimensions, weight and power requirements?

Machine dimensions are approximately L1115 × W800 × H1370 mm with a net weight of 300 kg. Total electrical power is 2.2 kW at 220 V, 50 Hz. Air consumption is about 0.25 m³/min at 0.8 MPa.

8. Does the machine include automatic functions like printing, counting and date coding?

Yes — the machine performs automatic measuring, filling, sealing, date printing (coding), counting and transporting as standard functions.

9. How easy is it to changeover between products or bag sizes?

Changeovers are straightforward thanks to servo control and adjustable tooling; bag length and width are adjustable within the machine ranges. Some format parts (film collar, sealing jaws, formers) may need manual swap-over. Exact changeover time depends on operator experience and requested bag format.

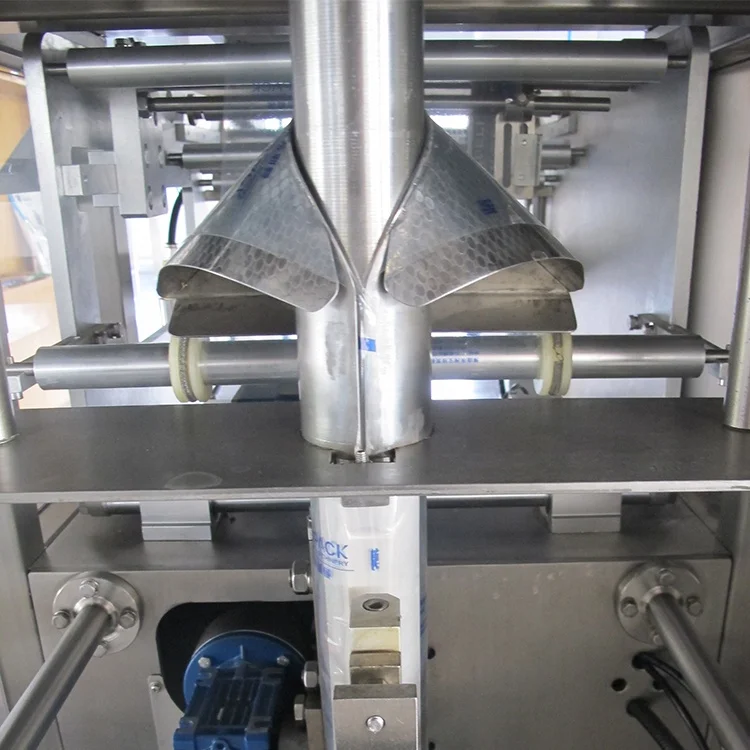

10. How is film feeding handled and how does it reduce film waste?

A double-belt pulling film system with servo-controlled film drawing provides stable material handling and precise indexing, minimizing film slip and reducing film loss.

11. What maintenance and cleaning are required?

Routine maintenance includes cleaning product-contact surfaces (stainless steel parts), checking and replacing wear items (seals, cutting knives, belts), lubricating moving parts per manual, and verifying electrical/air connections. Removable tooling and sanitary design simplify cleaning; follow supplier service schedule for optimal uptime.

12. Can the machine handle particulates or pieces in product (e.g., soups with solids)?

The machine is primarily designed for liquids and semi-liquids. Small particulates can be possible if the chosen filling system (pump/nozzle) and sealing allow passage. For soups with larger solids, confirm compatibility and consider an appropriate filler (e.g., piston or gear pump or special nozzle) with the supplier.

13. Are spare parts and after-sales support available?

Spare parts, optional accessories and technical support are normally available from the manufacturer or authorized distributor. Contact sales for recommended spare parts lists, lead times and service agreements.

14. What optional features or upgrades are available?

Common options include alternate PLC brands, different filling pumps for viscous products, heated nozzles or tanks, upgraded date/lot coders, specialized bag formers (e.g., DIMPLE SUS304), and tailored tooling for nonstandard bag types. Consult the supplier to configure options for your product and line speed.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading