B21, China Town Mall, Midrand

Ergonomic Design Suitable For Pipe From 2'' To 12'' With High Speed Cutter

- Section : Machinery

- Category : Metal & Metallurgy Machinery

- SKU : 1601053344347

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 03 Feb, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What pipe diameters does this machine support?

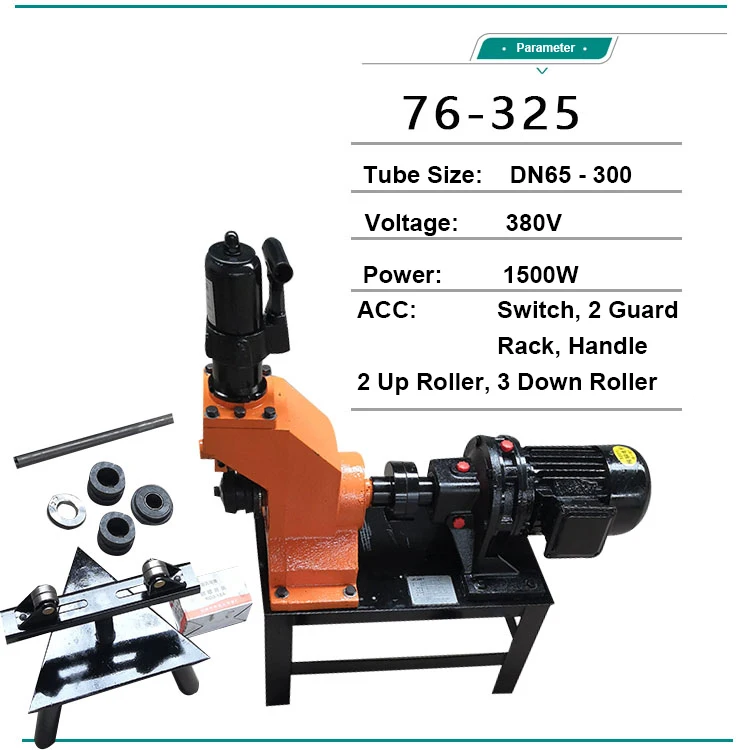

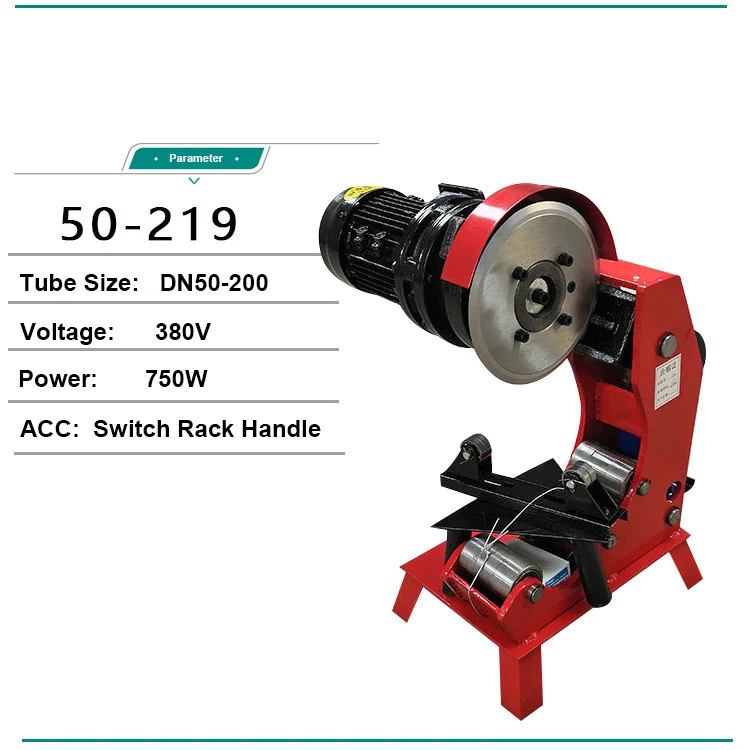

The GC-12-219 roll grooving machine processes pipe diameters from 76 mm to 219 mm (approximately 3.0" to 8.6"). Note: the product name reference to 2"–12" may reflect other model ranges; please confirm with sales if you need 50.8 mm (2") or 304.8 mm (12") capacity.

2. What is the maximum pipe wall thickness this machine can handle?

Maximum tube wall thickness is 6 mm (about 0.24").

3. What pipe types and materials can be grooved?

The machine is designed for round pipes and is commonly used on piping for fire protection, potable water, mining and general industrial applications. For specific materials (e.g., stainless steel, carbon steel, copper), confirm compatibility with your supplier.

4. What are the machine's motor, power and speed specifications?

Motor: 380 V, 1.1 kW, 50 Hz. Grooving speed (roller rotation) is 24 RPM.

5. Is this a cutter or a roll-grooving machine, and what does 'high speed cutter' mean?

This is a roll grooving machine that forms grooves by pressing the pipe between rotating pressure and forming rollers. The term 'high speed cutter' in the name refers to the efficient grooving/forming capability of the tooling; the machine's working rotation is specified at 24 RPM.

6. What are the machine dimensions and weight? Is it portable?

Dimensions: 650 × 310 × 760 mm. Weight: 85 kg. It is compact and relatively mobile for workshop use, but due to its weight it typically requires manual handling aids or two people for transport.

7. What are the key safety and ergonomic features?

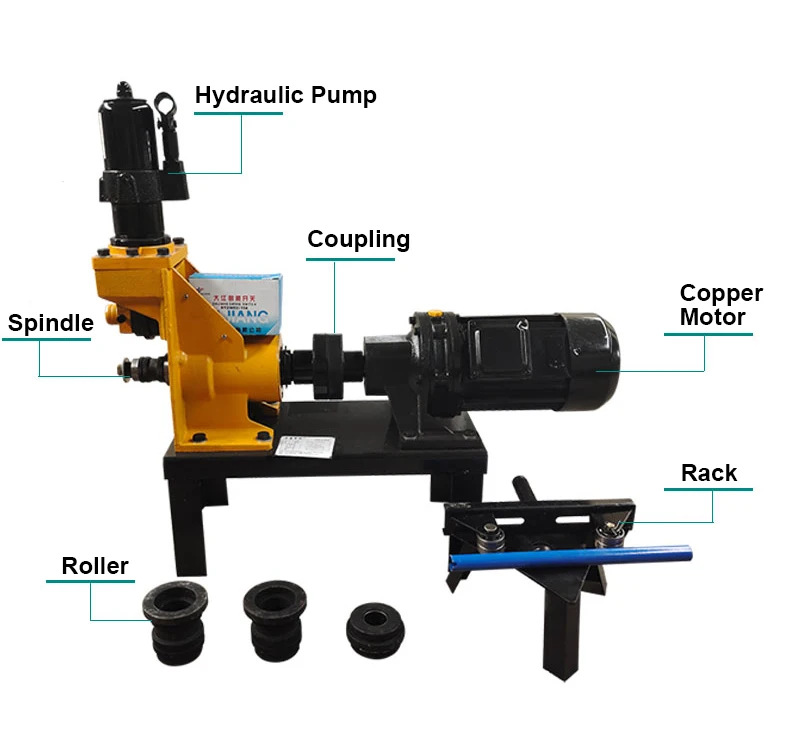

Features include a safety frame, compact ergonomic design, simple controls for safer operation, and an extending undercarriage for stable pipe support. Always use personal protective equipment and follow the operator manual for safe use.

8. How do you operate the machine (basic steps)?

Basic steps: secure the machine and power, place and center the pipe on the rollers, adjust the extending undercarriage/support as needed, engage the turning pressure wheel to start rotation, and slowly apply forming pressure with the convex roller to create the groove. Refer to the operator manual for full instructions and safety checks.

9. What maintenance is required?

Regular maintenance includes cleaning the rollers and housing, lubricating bearings and moving parts per the manual, inspecting rollers and forming dies for wear, checking motor mounts and electrical connections, and replacing worn tooling promptly to ensure groove quality.

10. Are replacement parts and tooling available?

Yes — common wear parts such as rollers, forming dies and bearings are typically available. Contact your supplier or sales representative with the model (GC-12-219) and part descriptions to order spares.

11. What payment methods and shipping terms are offered?

Accepted payment methods: T/T, L/C, PayPal, Western Union. Shipping terms: FOB Qingdao, China.

12. Does the machine require any special electrical hookup?

The standard motor is 380 V, 1.1 kW, 50 Hz. Ensure you have the appropriate three-phase supply or arrange for the correct power configuration with an electrician or the supplier if your local power differs.

13. What is the model number and where can I get technical specifications?

Model: GC-12-219 (Roll Grooving Machine). Technical specifications (motor, processing diameter, speed, weight, dimensions, max tube thickness) are listed with the product; contact the seller for full datasheets or user manuals.

14. Who do I contact for warranty, service or technical support?

Warranty and service terms are provided by the seller/manufacturer. For warranty coverage, installation support, spare parts or technical assistance, contact your point of sale or the manufacturer's service department; provide the model (GC-12-219) and serial number for faster support.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals