B21, China Town Mall, Midrand

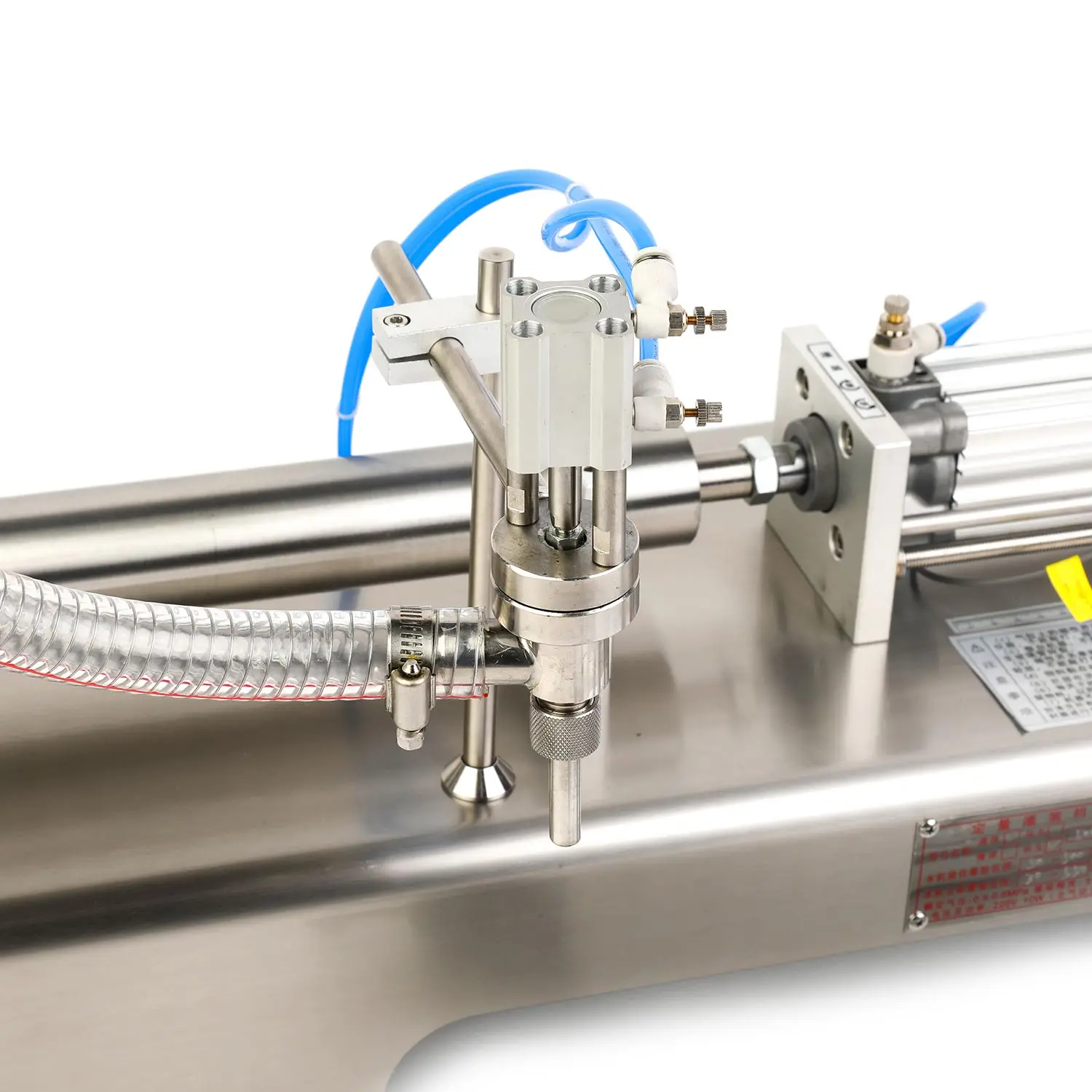

equipment supplier G1WYD Semi- automatic liquid filling machine

- Section : Machinery

- Category : Filling Machines

- SKU : 62089596416

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 21 Mar, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the G1WYD Semi-automatic liquid filling machine?

The G1WYD (Kunba) Semi-automatic Double Heads Paste Cosmetic Cream Filling Machine is a semi-automatic, motor-driven filling machine with two filling heads designed for accurate and efficient filling of liquids and pastes such as beer, milk, water, oil, juice and cosmetic creams.

2. What industries and products is this machine suitable for?

It is suitable for food & beverage (juices, milk, beer), cosmetics (creams, lotions), pharmaceutical/medical pastes and a range of chemical liquids and pastes used in packaging lines.

3. What container and packaging types can it fill?

The machine can handle cartons, cans, bottles, stand-up pouches, regular pouches and cases. Specific container sizes and shapes should be confirmed with the supplier for required tooling or adapters.

4. What is the filling speed and what affects it?

Filling speed ranges from 10 to 60 bottles per minute. Actual throughput depends on product viscosity, fill volume, container size, operator workflow and how quickly containers are presented to the machine.

5. What is the filling accuracy?

Filling accuracy is ≤1% under recommended operating conditions. Accuracy depends on correct setup, consistent product viscosity and proper maintenance.

6. Which liquids and viscosities can the machine handle?

It handles low-viscosity liquids like water, milk, juice and oils as well as medium-viscosity pastes and creams. Extremely high-viscosity or abrasive products may require evaluation and possible customization—please consult the supplier with sample materials.

7. What is the machine made of and why does that matter?

The machine frame and product-contact parts are made of SUS304 stainless steel, providing corrosion resistance, durability and ease of cleaning—important for food, beverage and cosmetic hygiene standards.

8. What are the electrical requirements?

Standard electrical options are 220V or 110V (single-phase). Confirm the specific voltage, phase and frequency required for your region before purchase.

9. What does 'semi-automatic' operation mean for the operator?

Semi-automatic means the machine performs filling cycles mechanically/electrically while an operator typically loads and positions containers, starts cycles and removes filled containers. It reduces manual filling labor but still requires human interaction.

10. How easy is the machine to clean and maintain?

SUS304 construction and a straightforward design make cleaning relatively easy. Routine maintenance includes cleaning product-contact surfaces after production runs, checking seals/nozzles, lubricating moving parts as recommended, and inspecting the motor and fittings periodically.

11. What certifications and warranty does it come with?

The machine carries CE and ISO certifications to meet international safety and quality standards and comes with a 1-year warranty. Warranty terms may vary by supplier—check the sales contract for details.

12. What are the machine dimensions and packaging for shipment?

Machine external dimensions are approximately 1080 × 460 × 360 mm. For shipment the machine is typically packed in wood packaging to protect it during transit.

13. What spare parts or core components should I expect to need?

The motor is the core driven component; common spare parts include seals, nozzles, valves, tubing and gaskets. It’s recommended to stock basic wear parts and order replacements through the supplier.

14. Is installation and operator training provided?

Many suppliers offer installation support and operator training either on-site or remotely—confirm availability, costs and scope of training with your sales representative prior to purchase.

15. Can the machine be customized or upgraded?

Customization options (for example different nozzle types, additional heads, different fill volumes or automation interfaces) are often available. Contact the supplier with your production requirements to discuss possible upgrades or custom configurations.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals