B21, China Town Mall, Midrand

Electric Ride Automation On Huge Floor Sweeper

- Section : Machinery

- Category : Other Cleaning Equipment

- SKU : 1601014820428

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 13 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the 'Electric Ride Automation On Huge Floor Sweeper'?

A large, electric ride‑on floor sweeper with optional automation features for high‑productivity sweeping of big indoor/outdoor areas. It combines ride‑on comfort, large hopper/brush capacity and choices of remote or autonomous navigation for industrial and municipal cleaning.

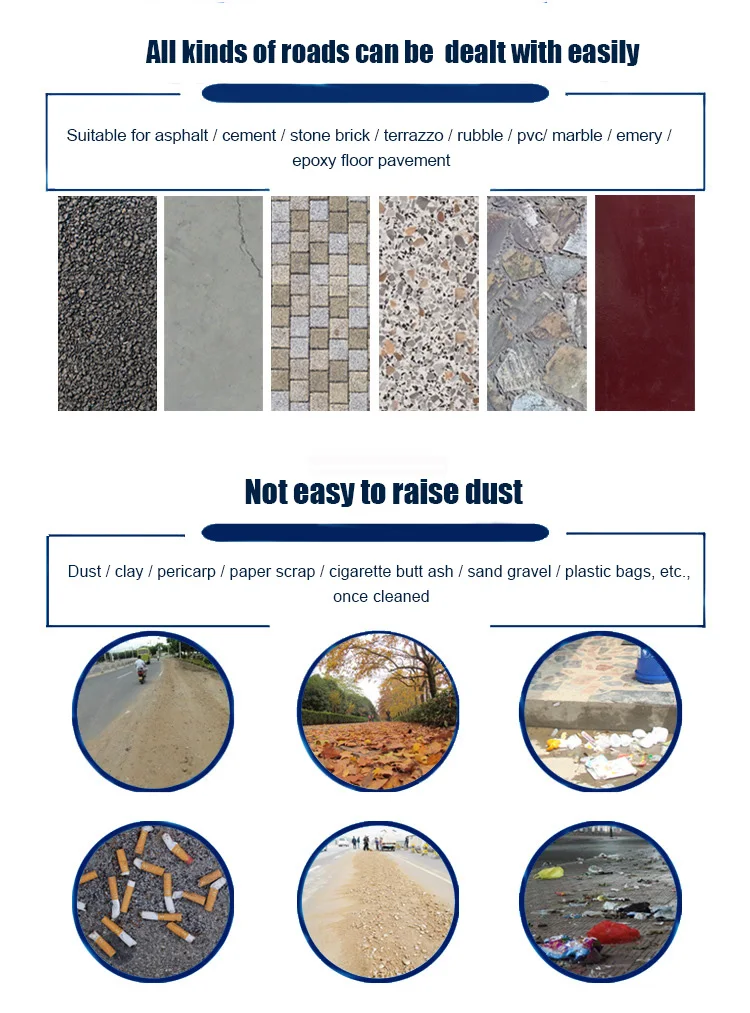

2. Which applications is this machine designed for?

Designed for warehouses, logistics centers, factories, airports, shopping centers, parking lots, campuses and municipal yards where large‑area, efficient cleaning is required.

3. What are the key features and benefits?

Key features include electric drive (zero tailpipe emissions), ride‑on ergonomics, large main and side brushes, high‑capacity debris hopper, modular filtration (including HEPA options), and optional automation such as remote control, obstacle avoidance and route mapping. Benefits are higher productivity, lower operating cost and safer, quieter operation.

4. What automation capabilities are available?

Automation options typically include remote control, semi‑autonomous modes, fully autonomous navigation with mapping, obstacle detection and avoidance using sensors (LiDAR/camera/ultrasonic), and GPS/RTK positioning for outdoor sites. Specific functions depend on selected model and accessory package.

5. What battery types, runtime and charging times are offered?

Machines use industrial lead‑acid or lithium battery packs. Typical runtime depends on battery choice and duty but commonly ranges from 4 to 10 hours per charge. Charging time varies (lead‑acid: 6–10 hours; lithium: 3–6 hours). Fast‑charge options and spare battery packages are available on request.

6. What are the typical cleaning widths and hopper capacities?

Cleaning width depends on brush configuration and model; typical sweeping widths range up to about 3 m with side brushes engaged. Hopper/debris capacities vary by model—commonly from several hundred liters up to around 1.5 m3 for the largest units. Exact figures depend on the selected model.

7. How effective is dust filtration?

The sweeper uses multi‑stage filtration. Options include primary mesh filters, cartridge filters and high‑efficiency (HEPA) filters for fine particulate capture. Water spray or pre‑separator options are available to reduce airborne dust during heavy dust operations.

8. What safety features does the machine include?

Standard safety features include emergency stop button, automatic parking brake, operator presence/seat sensor, safety lights and audible alarms. Automated versions add obstacle detection and automatic stop on obstruction. Configurable speed limits and zone restrictions are available for safe operation.

9. How noisy is the sweeper and is it suitable for indoor use?

Electric drive and brush systems are designed for low noise operation, making the machines well suited for indoor use and noise‑sensitive environments. Exact dB(A) levels depend on model and options, but electric sweepers are significantly quieter than diesel equivalents.

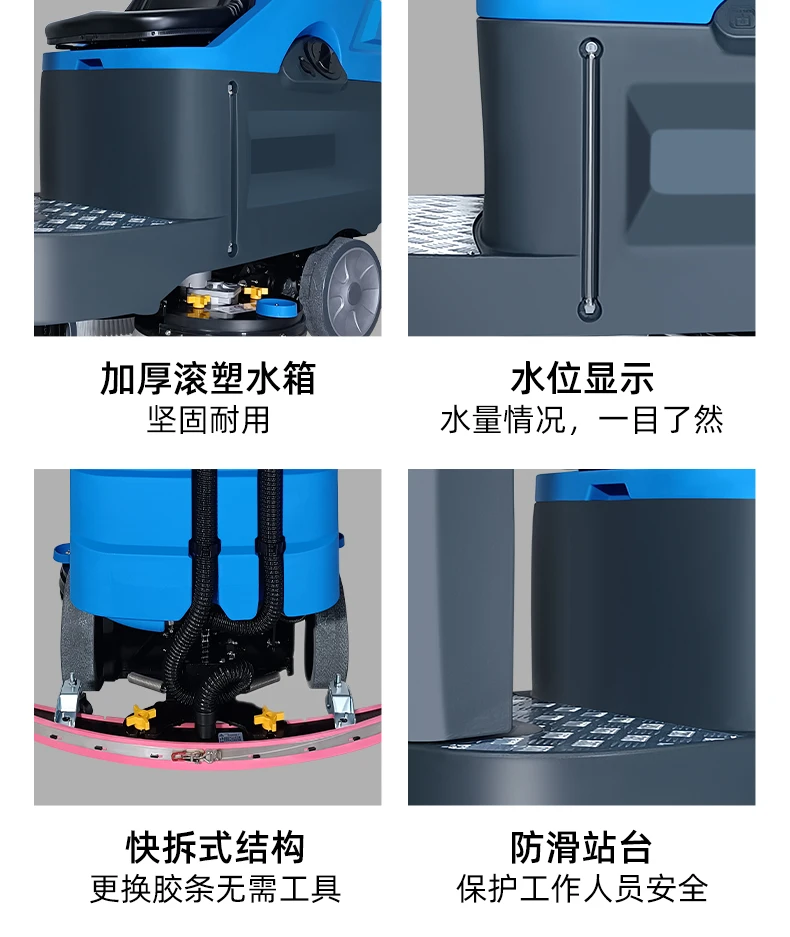

10. What maintenance is required and how often?

Routine maintenance includes daily brush and hopper inspection/cleaning, weekly filter checks, battery maintenance per manufacturer instructions, and periodic service of hydraulic/electrical systems. Typical preventive maintenance intervals are daily, monthly and annual checks; specific schedules are provided in the operator manual.

11. What warranty and after‑sales support do you offer?

Standard warranty terms vary by model but commonly include 12 months or a specified number of operating hours. PLSON provides spare parts, technical support, remote diagnostics (for automated units) and optional extended warranties and maintenance contracts.

12. Can the sweeper be customized or fitted with accessories?

Yes. Common customizations include different brush types, HEPA filtration, larger battery packs, water spray systems, specific lighting and signage, telematics packages, and bespoke paint or decals. Automation and sensor suites are offered as configurable options.

13. What certifications and manufacturing standards does the product meet?

PLSON has been manufacturing electric sweepers since 1988 and assembles machines on a domestic standard production line that meets automobile production standards. The company typically supports common certifications such as CE and ISO9001; specific certification packages can be provided per contract.

14. How do I purchase, and what are lead times and minimum order quantities?

You can contact PLSON sales for quotes, configuration options and ordering. Lead times depend on model and customization but commonly range from 30 to 60 days for production; expedited options may be available. Minimum order quantities depend on distributor agreements—single‑unit purchases are usually accepted for standard models.

15. Does PLSON provide operator training and installation for automated systems?

Yes. PLSON offers operator training, on‑site commissioning, system integration assistance and remote/onsite training for automated navigation, fleet management and maintenance procedures. Training packages can be included in purchase contracts or supplied as add‑ons.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading