B21, China Town Mall, Midrand

Diesel Wood Chipper for Efficient Farm Waste Management

- Section : Machinery

- Category : Forestry Machinery

- SKU : 62146766602

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 05 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What powers the Diesel Wood Chipper — a diesel engine or tractor PTO?

The product listing refers to a diesel-capable design but the units in the specification table are PTO-driven and require a tractor PTO. Typical models require 18–35 HP at a PTO speed of 540 RPM. If you need a self-contained diesel-engine version, contact the supplier to confirm availability and exact configuration.

2. What maximum branch diameter can the chipper handle?

Depending on the model, the chipper can process woody material with a maximum diameter of approximately 80–100 mm (about 3.1–4 inches). Actual capacity depends on wood type and moisture content.

3. What is the chipping capacity (output) per hour?

Typical working efficiency for the listed models is about 5–6 m3 per hour. Actual throughput varies with material species, moisture, operator feed rate and PTO power.

4. What PTO speed is required for proper operation?

The chipper is designed to operate at a PTO speed of 540 RPM (540 T/min). Ensure your tractor or PTO source can reliably maintain that speed.

5. What are the machine dimensions and weight?

The compact design is approximately 1600 x 2500 mm overall. Net weight varies by model and configuration — typical model weights range from about 195 kg to 305 kg. Confirm the exact model weight when ordering.

6. What are the hopper and rotor specifications?

Standard hopper sizes are shown as 500 x 500 x 700 mm (some variants 500 x 500 x 250 mm). Rotor diameter is 600 mm (25"). Knives are arranged as 4+1 pieces on the rotor in the supplied models.

7. What type of blades/knives does the chipper use and are they replaceable?

Knives and rollers are made from heat-treated special materials for longer service life. Knives are replaceable; the rotor uses 4+1 knife configuration. Keep spare knives on hand and follow the supplier's instructions for fitting and balancing.

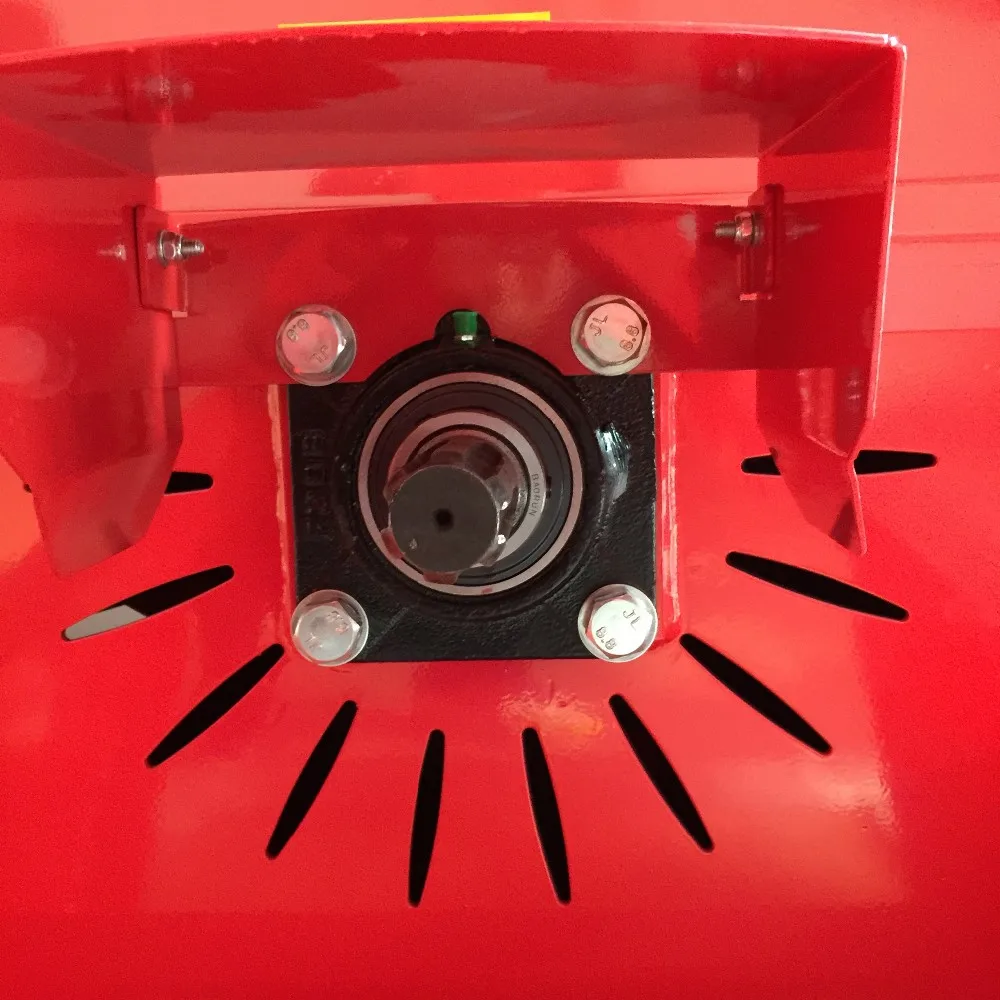

8. How durable are the gearbox and gears, and what maintenance do they need?

The machine is equipped with heavy-duty gears and a robust gearbox to withstand farm use. Regular maintenance includes gearbox oil checks/changes per the manual, periodic inspection for wear, and ensuring shaft/driveshaft alignment. Follow the maintenance schedule provided with the machine.

9. What mobility features does the chipper have for moving around the farm?

The chipper is fitted with heavy-duty wheels (20*7-8) for easy movement and transport around the farm. Its compact footprint also helps with maneuverability and storage.

10. Is color customization available?

Yes — color customization is available on request so you can match the chipper to your farm equipment or branding. Confirm lead time and any additional cost with the supplier.

11. Is the product certified and inspected before delivery?

Yes — designs are produced according to CE requirements and each product is inspected before delivery. The manufacturer has exported to Europe since 2003, indicating experienced production and quality control processes.

12. What safety precautions should operators follow?

Always read and follow the operator manual. Recommended practices include: wear appropriate PPE (gloves, eye and ear protection), keep bystanders well away, do not feed hands or loose clothing into the hopper, shut off PTO and ensure all moving parts are stopped before maintenance, and only allow trained operators to use the machine.

13. What are common uses for the wood chips produced?

Produced chips are suitable for mulch, composting, biomass fuel, pathway surfacing and general farm/landscape waste management. Chip size depends on feed material and model settings.

14. Are spare parts, warranty and after-sales support available?

Spare parts and after-sales support are available — contact the supplier for details on parts availability, warranty terms, service options and any local dealer or service network. Given the manufacturer's long export history, they generally provide parts and technical support; confirm specifics when ordering.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading