B21, China Town Mall, Midrand

D-215 Anchor Drilling Machine For Construction Piling

- Section : Machinery

- Category : Engineering & Construction Machinery

- SKU : 62324892162

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 05 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What applications is the D-215 Anchor Drilling Machine designed for?

The D-215 is built for anchor and minipile engineering used in deep pits, subway and tunnel construction, railways, highways and disaster relief projects. It works in a wide range of geological strata.

2. What are the key technical specifications of the D-215?

Key specs include Cummins QSC8.3-C215 diesel engine (160 kW), 24 V electrical system, fuel tank 380 L, hydraulic oil tank 500 L, feed stroke 4000 mm, feed/retraction force 100 kN, percussion frequency up to 1150 times/min, and transport dimensions 7800×2280×2700 mm with a weight of 13,400 kg.

3. What engine powers the rig and what is its output?

The rig is powered by a Cummins QSC8.3-C215 turbocharged diesel engine with a maximum power output of 160 kW.

4. Which drilling modes does the D-215 support?

The D-215 supports rotary and percussive (rotary-percussion) drilling modes, enabling use with a variety of drilling tools and formations.

5. What are the torque and rotational speed ranges?

Maximum torque is 8,750 N·m at high speed and 15,800 N·m at low speed. Rotational speeds are 0–120 rpm (high speed) and 0–60 rpm (low speed).

6. What are the feed and retraction performance characteristics?

Feed stroke is 4,000 mm. Feed and retraction force are 100 kN. Feed/retraction speeds are Low: 0–15 m/min and High: 0–50 m/min.

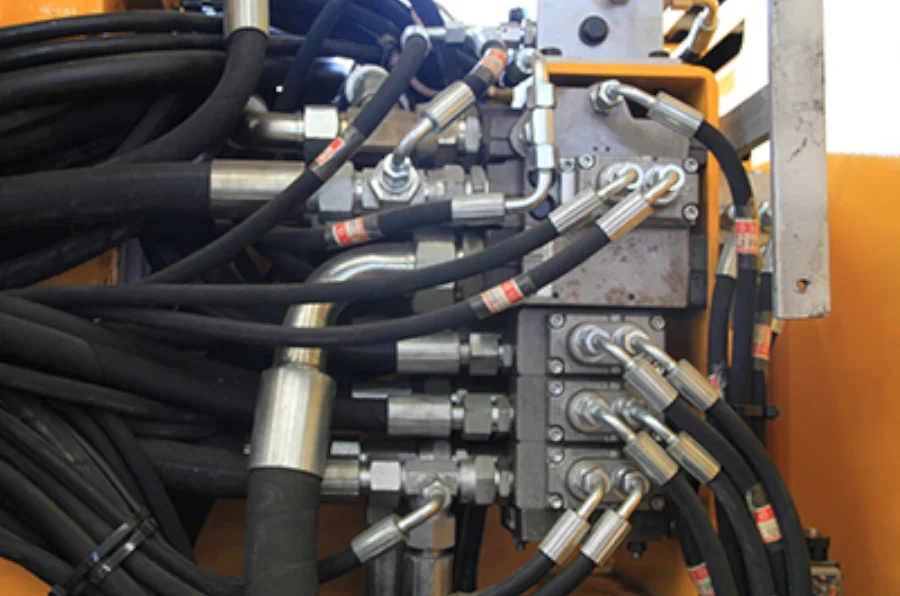

7. What are the hydraulic system features?

The rig uses a multifunctional hydraulic system with load-sensing technology to improve efficiency. It has three hydraulic circuits with operating pressures up to 24, 20 and 25 MPa respectively (as specified).

8. How is mobility provided and what terrain can it handle?

The D-215 is crawler-mounted with a high-traction crawler system designed by Bealong, providing smooth and reliable movement across diverse road and worksite conditions.

9. What mast features help with positioning and angling?

The drill mast offers large swing and tilt angles for flexible positioning and efficient operation under various working conditions, enabling inclined and vertical drilling as required.

10. What operator controls and ergonomics does the machine offer?

The rig has a swingable, integrated operation panel and top-drive power head with electric control cylinders to provide easier, flexible and centralized operation for drillers.

11. Which components and accessories are included or available?

Standard components include the top-drive power head, power station, holder, engine and electric control cylinder. The D-215 is compatible with common piling accessories (drill rods, bits, casings, Kelly systems, grout equipment). Specific tooling and optional attachments are available on request.

12. How easy is maintenance and what after-sales support is available?

The D-215 is designed for economical operation and easy maintenance. Bealong provides spare parts and after-sales support; for specific service packages, parts availability and lead times, contact your supplier or the manufacturer directly.

13. What are the transport and site installation requirements?

Transport dimensions are 7800×2280×2700 mm and operating weight is about 13,400 kg. Site requirements depend on local lifting/rigging regulations; the rig is crawler-mounted and typically requires level access for assembly and commissioning. Confirm local transport permits and lifting equipment for delivery.

14. Are there recommended safety practices for operating the D-215?

Operate only with trained personnel, follow manufacturer safety manuals, use required PPE, verify ground stability, secure the work area, perform pre-shift checks (engine, hydraulic lines, controls), and follow lockout/tagout procedures during maintenance.

15. What warranty, training and operator support options are offered?

Warranty, training and support vary by supplier and region. Typically manufacturers or distributors provide operator training, commissioning assistance and a warranty for a defined period. Contact your local dealer for details on warranty terms, training programs and after-sales packages.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading