B21, China Town Mall, Midrand

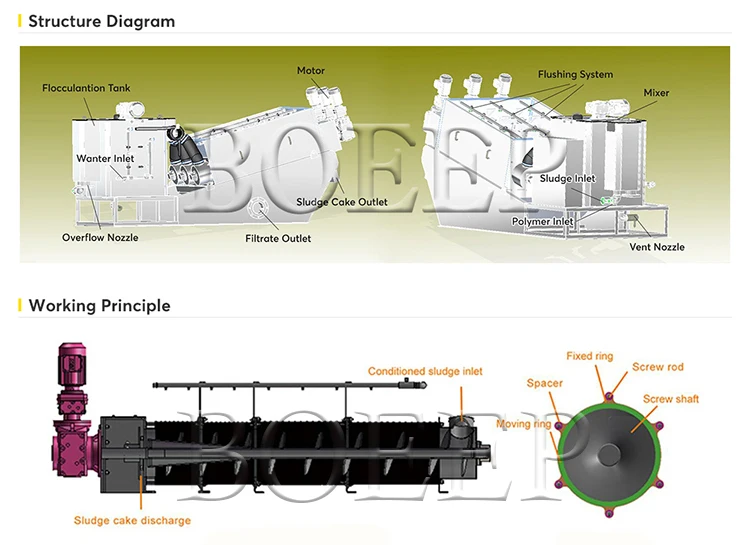

Clog-Free Self-Clean Volute Type Screw Press Multi Disk Sludge Dewatering Machine For Kitchen Food Waste Water Treatment

- SKU : 1601024636000

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 02 Mar, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the main function of the Clog-Free Self-Clean Volute Type Screw Press Multi Disk Sludge Dewatering Machine?

The main function is to dewater sludge from kitchen food waste water treatment using screw extrusion principles for solid-liquid separation.

2. How does this machine achieve clog-free operation?

The design includes a volute screw mechanism with moveable and fixed annular plates that create pressure for efficient solid-liquid separation, minimizing the risk of clogs.

3. What types of sludge can this machine handle?

It is suitable for any type of sludge, including those rich in oil and grease.

4. What are the energy consumption characteristics of this machine?

The machine is designed for low energy consumption, ensuring efficient operation while reducing operating costs.

5. Is there a need for sludge thickening before using this machine?

No, there is no need for sludge thickening as the machine can effectively dewater sludge directly.

6. How noisy is the operation of this machine?

The machine operates with minimal noise, making it suitable for environments where noise reduction is a priority.

7. What is the maintenance requirement for this machine?

The machine requires minimal maintenance, which helps to keep operational costs low.

8. Can this machine operate continuously?

Yes, it is capable of operating 24/7, making it ideal for continuous sludge treatment processes.

9. What is the sludge treating capacity of the MYDL101 model?

The MYDL101 model has a sludge treating capacity of 3-6 kg/h.

10. What is the maximum flow treating capacity of the MYDL202 model?

The MYDL202 model has a maximum flow treating capacity of approximately 1.8 m3/h.

11. What are the polymer consumption characteristics of this machine?

The machine is designed to have low polymer consumption, which reduces chemical costs in the dewatering process.

12. How does this machine compare to traditional dewatering methods?

This machine offers advantages such as lower energy and water consumption, minimal noise, and does not require prior sludge thickening, making it more efficient than traditional methods.

13. What models are available in this product line?

The product line includes models like MYDL101, MYDL131, MYDL201, MYDL202, MYDL301, MYDL302, MYDL303, MYDL304, MYDL351, MYDL352, MYDL353, MYDL354, MYDL401, MYDL402, MYDL403, and MYDL404, each with varying capacities.

14. What is the benefit of using a multi-disk design in this machine?

The multi-disk design enhances the efficiency of solid-liquid separation by increasing the surface area for dewatering, resulting in better performance.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals