B21, China Town Mall, Midrand

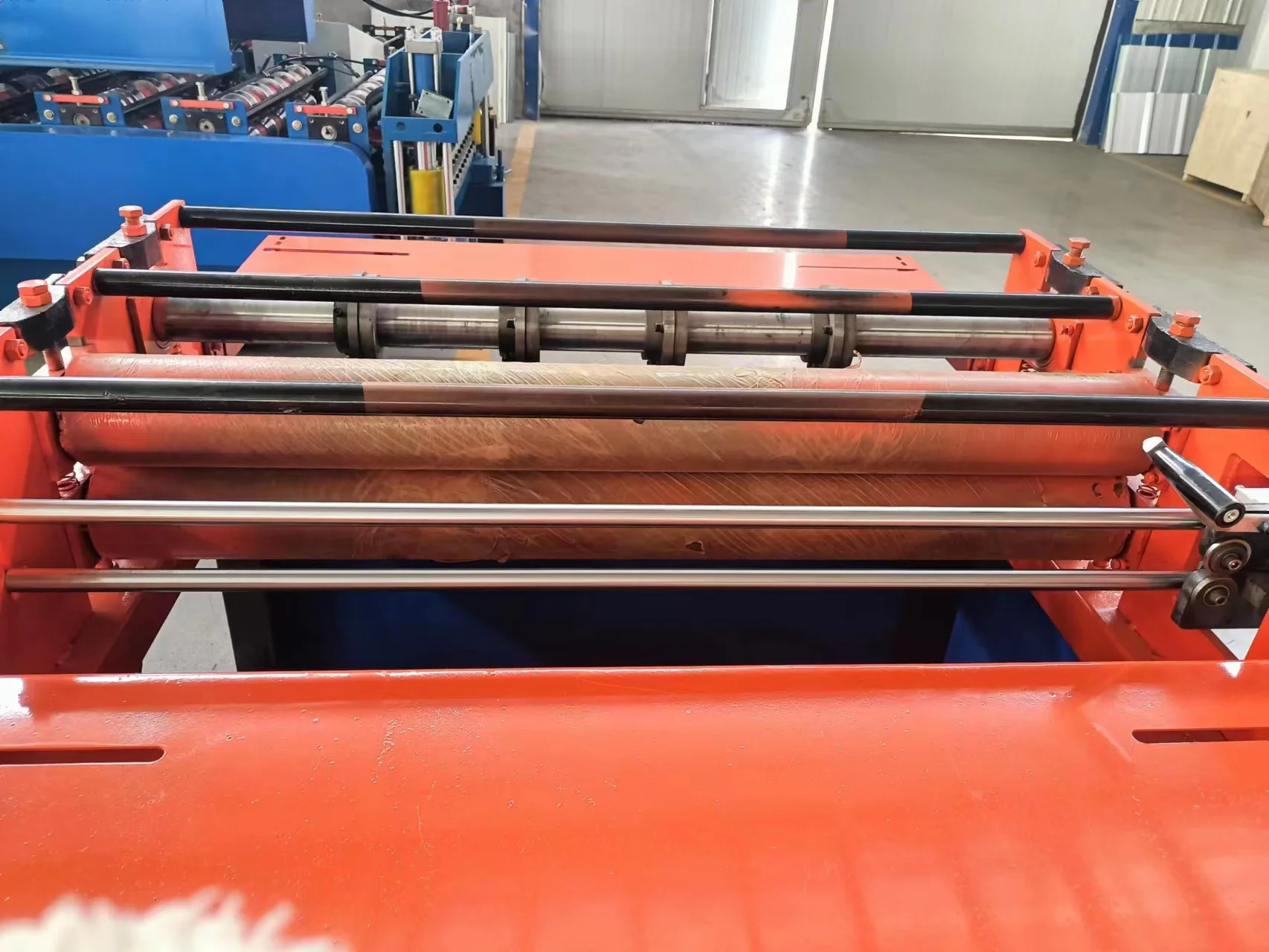

Carbon Steel Slitting Machine Color Steel Metal Sheet Plate Coil Slitting Cutting/slitter Cutter Machine

- Section : Machinery

- Category : Industrial Machinery

- SKU : 1600910105242

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 23 Mar, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What materials can the Carbon Steel Slitting Machine process?

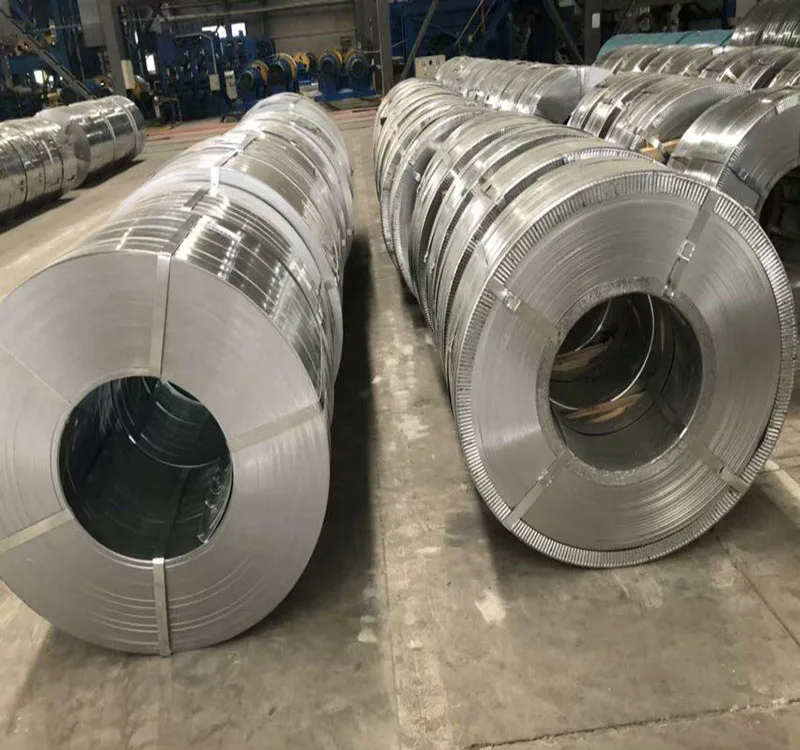

The Carbon Steel Slitting Machine can process various materials including steel, aluminum, color steel, and PPGI.

2. What is the thickness range of materials that can be used with this machine?

This machine can handle raw material thicknesses ranging from 0.2mm to 0.7mm.

3. What is the maximum running speed of the slitting machine?

The machine operates at a running speed of up to 15 meters per minute.

4. What is the optimal working environment temperature for this machine?

The optimal working environment temperature for the machine is between -10℃ to 30℃.

5. Can the machine create strips of different widths?

Yes, the machine features adjustable rollers that allow you to create strips of widths ranging from 2 to 9 strips.

6. What is the diameter of the feeding roller shaft?

The feeding roller shaft diameter is 70mm.

7. How does the feeding device protect the raw material surface?

The feeding device uses rubber rollers to protect the surface of the raw material during processing.

8. Is this machine suitable for beginners in metal processing?

Yes, the Carbon Steel Slitting Machine is compact and easy to operate, making it an excellent choice for beginners.

9. What type of drive does the machine use for operation?

The machine is motor-driven, which ensures efficient operation and ease of use.

10. How can I adjust the slit blade for different strip widths?

The slit blade is designed to be easily adjustable, allowing you to customize the width of the strips being cut.

11. What are the main applications of this slitting machine?

This machine is ideal for slitting steel strips for construction, processing stainless steel for kitchen equipment, cutting aluminum for decorative purposes, and manufacturing color steel sheets.

12. Does the machine have a compact design?

Yes, the Carbon Steel Slitting Machine has a compact size, making it easy to store and move.

13. What transmission system does the machine use?

The machine features a gear and chain drive transmission system for smooth performance.

14. Can this machine be used for cold rolled and silicon steel?

Yes, the machine is suitable for processing cold rolled and silicon steel, as well as tinplate and various metal coils.

15. What is the price range for the Carbon Steel Slitting Machine?

The machine is competitively priced, making it an affordable option for new businesses entering the metal processing industry.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals