B21, China Town Mall, Midrand

BLK-50-2 Charcoal Briquette Machine - Coconut Shell Charcoal Making Machine

- Section : Machinery

- Category : Other Agricultural Equipment

- SKU : 1600883862905

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 31 Mar, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What types of raw materials can the BLK-50-2 machine process?

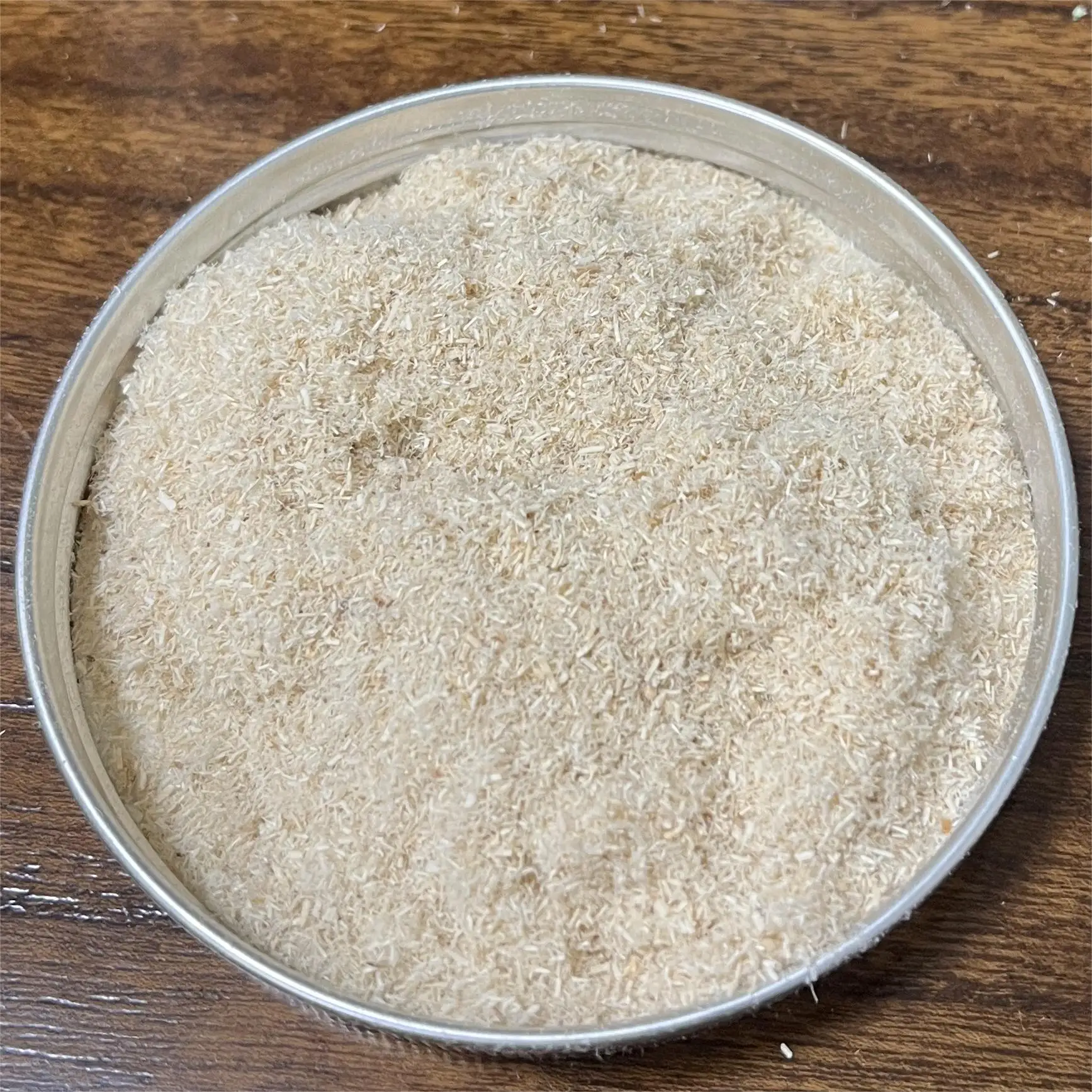

The BLK-50-2 machine can process a variety of biomass materials, including sawdust, coconut shells, straw, rice husk, bamboo, bagasse, and peanut seedlings.

2. What is the production capacity of the BLK-50-2 Charcoal Briquette Machine?

The BLK-50-2 model has a production capacity of 200-300 kg/h, making it suitable for medium to large-scale production.

3. Is the BLK-50-2 machine energy efficient?

Yes, the BLK-50-2 is designed with energy efficiency in mind, utilizing advanced technology to minimize energy consumption while maximizing output.

4. What is the finished product produced by the BLK-50-2 machine?

The BLK-50-2 machine produces hexagonal biomass briquettes that are ideal for use as eco-friendly fuel alternatives.

5. What are the dimensions and weight of the BLK-50-2 machine?

The machine has dimensions of 1770 x 660 x 1450 mm and weighs 800 kg.

6. Does the BLK-50-2 come with a warranty?

Yes, the BLK-50-2 comes with a 1-year warranty, ensuring high-quality performance and reliability.

7. Can the design of the BLK-50-2 be customized?

Yes, the BLK-50-2 can be customized with options for color and modifications to meet specific industry requirements.

8. What industries can benefit from using the BLK-50-2 machine?

The BLK-50-2 is ideal for industries involved in biomass energy production, charcoal manufacturing, and environmental sustainability initiatives.

9. How does the control system of the BLK-50-2 machine work?

The machine features an advanced PLC control system that provides precise control over the production process, ensuring consistency and quality in the finished products.

10. What are the key features of the BLK-50-2 machine?

Key features include high-efficiency biomass briquette press, energy-saving operation, versatile application, durable components, compact design, and high production capacity.

11. What is the maintenance requirement for the BLK-50-2 machine?

Regular maintenance includes checking oil levels for the lubrication system, ensuring the components are free from wear, and conducting routine inspections to maintain optimal performance.

12. Is training provided for operating the BLK-50-2 machine?

Yes, training is typically provided to ensure users can operate the machine safely and effectively, maximizing its performance.

13. What is the briquette size produced by the BLK-50-2 machine?

The machine produces hexagonal briquettes with an outer diameter of 50-60 mm and an aperture of 15-20 mm.

14. How does the BLK-50-2 contribute to environmental sustainability?

The BLK-50-2 machine helps recycle biomass waste materials like sawdust and coconut shells into eco-friendly fuel, reducing reliance on fossil fuels and promoting sustainable practices.

15. What safety features are included in the BLK-50-2 machine?

The machine is built with durable materials and components to ensure reliability; it also includes safety mechanisms to prevent operational hazards during use.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading