B21, China Town Mall, Midrand

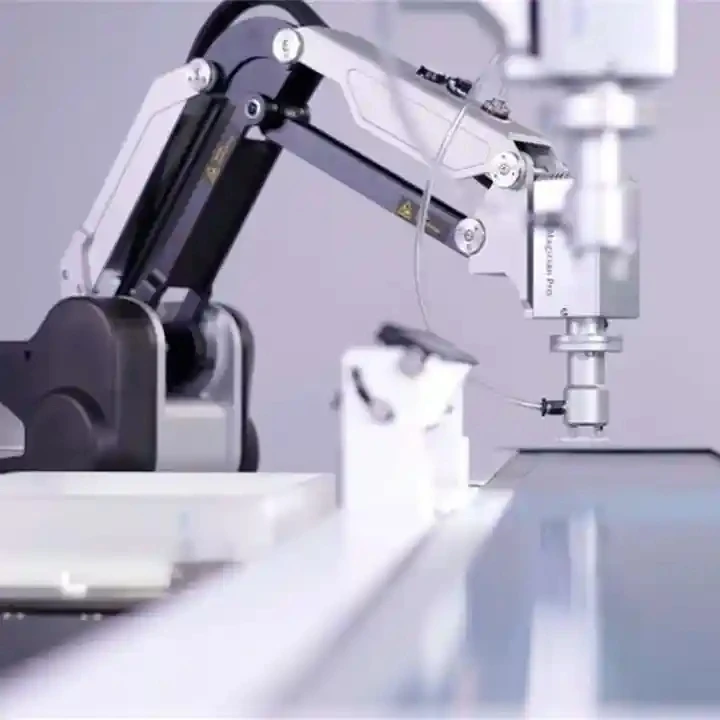

Best MG400 Desktop Robot Arm Industrial automation Equipment

- Section : Machinery

- Category : Industrial Machinery

- SKU : 1600836904780

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 11 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the Best MG400 Desktop Robot Arm (Dobot MG400)?

The Dobot MG400 is a 4-axis desktop robot arm designed for precise pick-and-place and light industrial automation tasks. It provides a compact footprint with a 440 mm working radius and is built for repeated, accurate operations in manufacturing, electronics assembly, and labs.

2. What are the key specifications of the MG400?

Key specs: 4 axes, maximum payload 0.5 kg, working radius 440 mm, repeatability ±0.05 mm, rated voltage DC 48V, weight 11 kg, made from aluminum alloy and ABS plastic, communications via TCP/IP, Modbus and Wi‑Fi, 36‑month warranty.

3. Which applications and industries is the MG400 best suited for?

Ideal for pick-and-place, small-parts assembly, PCB handling, testing and inspection, laboratory automation and light material handling tasks in electronics, small-scale manufacturing and research labs.

4. How is the MG400 programmed and controlled?

The arm supports network-based control through TCP/IP and Modbus and can be controlled over Wi‑Fi. Dobot typically provides control software and developer SDKs/APIs for custom integration; check with your supplier for available software packages and documentation.

5. Can the MG400 integrate with PLCs, vision systems or other automation equipment?

Yes. Communication protocols such as Modbus and TCP/IP enable integration with PLCs, PCs and networked devices. Vision and other sensors can be integrated via the controller or host PC—consult the supplier for recommended integration examples.

6. What are the power requirements and is a power supply included?

The MG400 operates on DC 48V. Whether a power adapter is included depends on the seller or kit configuration; confirm with your vendor before purchase.

7. How accurate and repeatable is the MG400?

The MG400 offers a repeatability of ±0.05 mm, making it suitable for precise pick-and-place and repeatable positioning tasks.

8. What mounting options are available for desktop use?

The unit is designed for desktop/benchtop deployment. For exact base dimensions, hole patterns and mounting hardware recommendations, refer to the product datasheet or ask the vendor for mechanical drawings.

9. What safety features does the MG400 include?

Specific safety features vary by configuration. Typical safety measures include software motion limits, emergency stop integration and the ability to add external safety devices. Always follow local safety regulations and implement required guards, sensors or emergency stops in your application.

10. What maintenance does the MG400 require?

Routine maintenance generally includes keeping the arm and joints clean, periodic inspection of cables and connectors, firmware/software updates and following any calibration checks recommended in the user manual. Refer to the supplied maintenance guide for intervals and procedures.

11. What warranty and support are provided?

The MG400 comes with a 36‑month warranty. For warranty service, spare parts, repairs or technical support, contact the reseller or manufacturer support channel and keep your proof of purchase available.

12. Are spare parts, end effectors or grippers available?

Various end effectors, grippers and accessory kits are commonly available for Dobot arms. Availability of specific parts or custom tooling should be confirmed with your supplier; they can provide compatible grippers, mounting adapters and replacement components.

13. What are the environmental and operating conditions for the MG400?

The product description does not list exact environmental specs. The MG400 is intended for indoor industrial/bench environments. For rated operating temperature, humidity limits and ingress protection, request the detailed specifications from the vendor or datasheet.

14. Where is the MG400 manufactured and what is its shipping weight?

The MG400 is manufactured in Guangdong, China. The listed weight for the unit is 11 kg; packaged weight will be higher—check with the seller for shipping details.

15. Does the MG400 have certifications (CE, RoHS, UL) or compliance documentation?

Certification details are not provided in the basic description. If you require CE, RoHS, UL or other compliance documents for regulatory or procurement reasons, request the certificates from your supplier before purchase.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading