B21, China Town Mall, Midrand

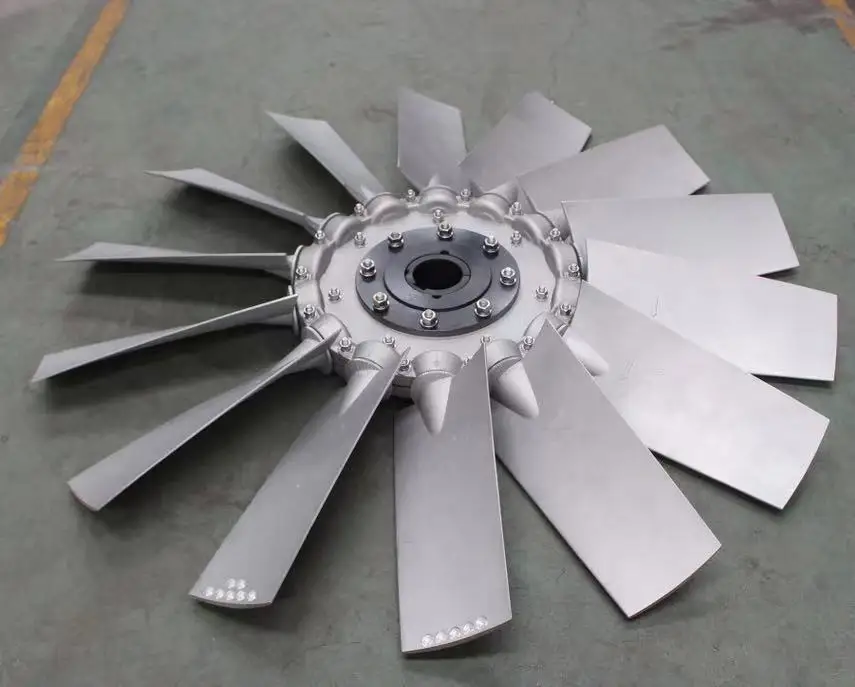

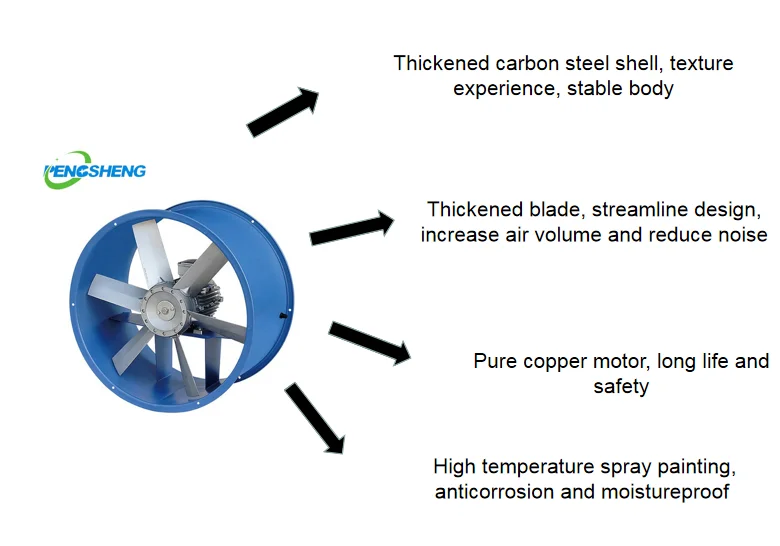

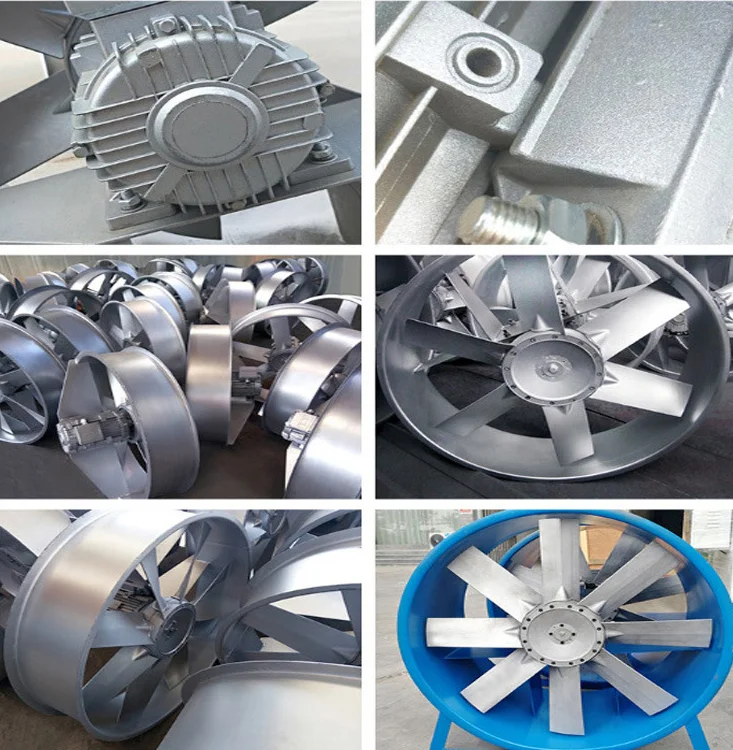

Axial Flow Fan Industrial Exhaust fan Pipe Type Post Type Fixed 200-1000mm

- Section : Machinery

- Category : Engineering & Construction Machinery

- SKU : 1601104616999-1

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 05 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What environments are the Axial Flow Fans suitable for?

The Axial Flow Fans are designed for explosive environments, making them ideal for industries such as oil refining, chemical, medicine, and military applications.

2. What is the temperature class range for the explosion-proof fans?

These fans are designed to operate in hazardous environments with temperature classes ranging from T1 to T4.

3. Are the fans resistant to moisture and corrosion?

Yes, the fans feature moisture-proof and anti-corrosion properties, making them suitable for high moisture and corrosive conditions.

4. Can the blades of the fan be adjusted?

Yes, the fan blades can be adjusted to optimize airflow and performance based on specific requirements.

5. How noisy are these fans during operation?

The fans are engineered to operate quietly, which helps in reducing noise pollution and creating a more comfortable work environment.

6. What are the installation options for these fans?

The fans offer multiple installation types, including wall-mounted, dusted, post, and fixed types for flexible installation options.

7. What materials are used in the construction of the fan?

The frame is made of SS304 stainless steel for high durability, while the blades are made of high-quality, corrosion-resistant material. The motor uses 100% copper wire for maximum efficiency.

8. What is the power consumption of the fans?

Power consumption varies by model, ranging from 0.18 kW for the 250mm model to 5.5 kW for the 1000mm model.

9. What is the air volume capacity of the Axial Flow Fans?

The air volume capacity ranges from 2100 m³/h for the 250mm model to 36000 m³/h for the 1000mm model.

10. Are these fans safe to use in hazardous locations?

Yes, these fans are specifically designed to be explosion-proof, ensuring safe operation in hazardous locations.

11. What industries can benefit from using these fans?

Industries such as oil refineries, chemical plants, pharmaceutical manufacturing, military and aerospace applications, and storage facilities with explosive materials can benefit from these fans.

12. How can I ensure compliance with safety regulations when using these fans?

These fans are built to meet high safety standards and are designed for hazardous environments, ensuring compliance with relevant safety regulations.

13. What is the total pressure range for the fans?

Total pressure ranges from 90 Pa for the 250mm model to 250 Pa for the 1000mm model.

14. What makes these fans energy-efficient?

The fans are designed for low noise and energy consumption, which reduces overall energy costs while maintaining effective ventilation.

15. Is there a warranty on the Axial Flow Fans?

Warranty details may vary by supplier or manufacturer, so it is recommended to check with your vendor for specific warranty terms and conditions.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading